Transparent luminescent mosaic glass and preparation method thereof

A technology of luminous glass and mosaic, applied in the field of mosaic, can solve the problems of affecting the dazzling effect of lighting, poor luminous effect, etc., and achieve the effects of easy implementation, simple preparation steps and good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

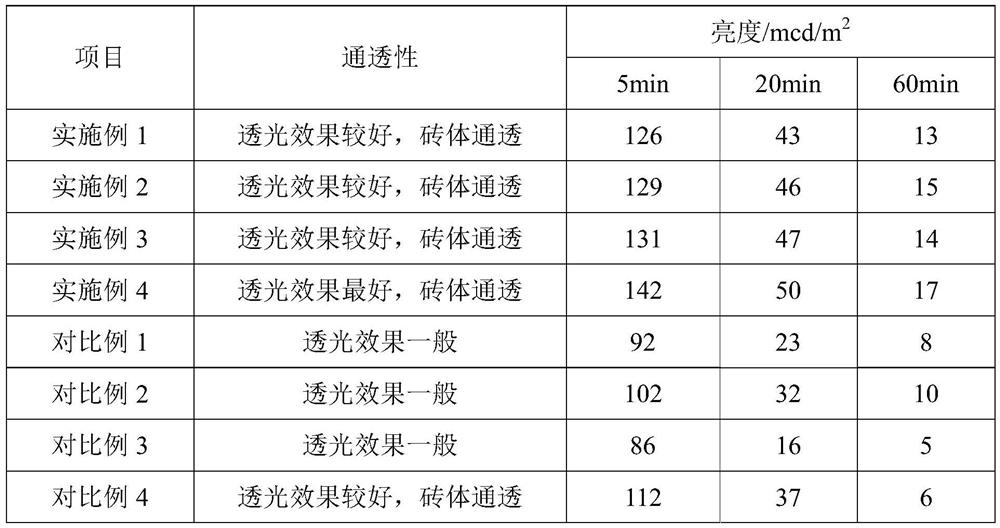

Examples

Embodiment 1

[0027] A transparent luminescent glass mosaic, comprising the following components by weight:

[0028] 60 parts of glass powder, 5 parts of potassium feldspar, 10 parts of albite, 1 part of dolomite, 0.1 part of luminescent material, 3 parts of amorphous transparent fluororesin, 0.1 part of emulsifier.

[0029] The preparation method of the above-mentioned transparent luminescent glass mosaic includes the following preparation steps:

[0030] S1: First put the amorphous transparent fluororesin into a high-temperature melting furnace at 650°C-700°C, melt at high temperature to form a solution, then add luminescent material to disperse the luminescent material in the solution, and then granulate to obtain a resin containing reflective material particles;

[0031] S2: Mix the glass powder, potassium feldspar, albite, dolomite, emulsifier and the resin particles obtained in step S1 evenly, then add it to a high-temperature melting furnace at 700°C-800°C, and melt at a high temper...

Embodiment 2

[0033] A transparent luminescent glass mosaic, comprising the following components by weight:

[0034] 65 parts of glass powder, 10 parts of potassium feldspar, 12 parts of albite, 5 parts of dolomite, 0.5 part of luminescent material, 5 parts of amorphous transparent fluororesin, and 0.5 part of emulsifier.

[0035] The preparation method of the above-mentioned transparent luminescent glass mosaic includes the following preparation steps:

[0036] S1: First put the amorphous transparent fluororesin into a high-temperature melting furnace at 650°C-700°C, melt at high temperature to form a solution, then add luminescent material to disperse the luminescent material in the solution, and then granulate to obtain a resin containing reflective material particles;

[0037] S2: Mix the glass powder, potassium feldspar, albite, dolomite, emulsifier and the resin particles obtained in step S1 evenly, then add it to a high-temperature melting furnace at 700°C-800°C, and melt at a high ...

Embodiment 3

[0039] A transparent luminescent glass mosaic, comprising the following components by weight:

[0040] 70 parts of glass powder, 15 parts of potassium feldspar, 15 parts of albite, 8 parts of dolomite, 1 part of luminescent material, 10 parts of amorphous transparent fluororesin, and 1 part of emulsifier.

[0041] The preparation method of the above-mentioned transparent luminescent glass mosaic includes the following preparation steps:

[0042] S1: First put the amorphous transparent fluororesin into a high-temperature melting furnace at 650°C-700°C, melt at high temperature to form a solution, then add luminescent material to disperse the luminescent material in the solution, and then granulate to obtain a resin containing reflective material particles;

[0043] S2: Mix the glass powder, potassium feldspar, albite, dolomite, emulsifier and the resin particles obtained in step S1 evenly, then add it to a high-temperature melting furnace at 700°C-800°C, and melt at a high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com