High-voltage ceramic insulated dark blue glaze

A high-voltage porcelain, deep blue technology, applied in the field of electric porcelain

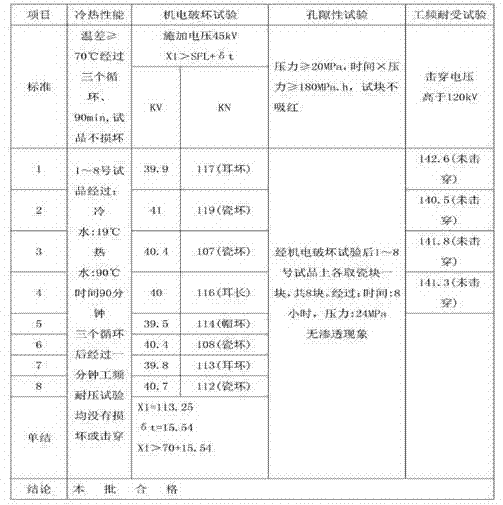

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The high-voltage porcelain insulating dark blue glaze contains the following components by weight: high potassium and low iron feldspar 10-50, Yichun quartz powder 5-25, Yunnan kaolin 3-20, Guangdong Xinhui soil 2-15, limestone 2-10, Forged talc 2-10, spodumene 3-15, barium carbonate 1-3, albite feldspar 2-10, cobalt blue agent 1-8, among them, the chemical composition requirement of high potassium and low iron feldspar is SiO 2 =66.2%, AI 2 o 3 =16.0%, Fe 2 o 3 =0.2%, CaO=0.7%, MgO=0.5%, K 2 O=11.5%, Na 2 O=3.0%, LL=0.1%; the chemical composition requirement of Yichun quartz powder is SiO 2 =98.9%, Fe 2 o 3 =0.1%, K 2 O=0.15%; the chemical composition requirement of Yunnan kaolin is SiO 2 =44%, AI 2 o 3 =37.5%, Fe 2 o 3 =0.5%, CaO=0.6%, MgO=0.4%, K 2 O=0.1%, Na 2 O=0.8%, LL=15%; the chemical composition requirement of Guangdong Xinhui soil is SiO 2 =48.9%, AI 2 o 3 =32%, Fe 2 o 3 =1.1%, TiO 2 =0.5%, CaO=0.8%, MgO=0.4%, K 2 O=1%, Na 2 O=0.5%, LL=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com