Method for preparing cobalt blue material for decorating ceramic

A blue and ceramic technology, applied in the field of preparation of cobalt blue materials for ceramic decoration, can solve the problems of poor acid resistance of cobalt blue materials, no acid resistance, good cobalt blue materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

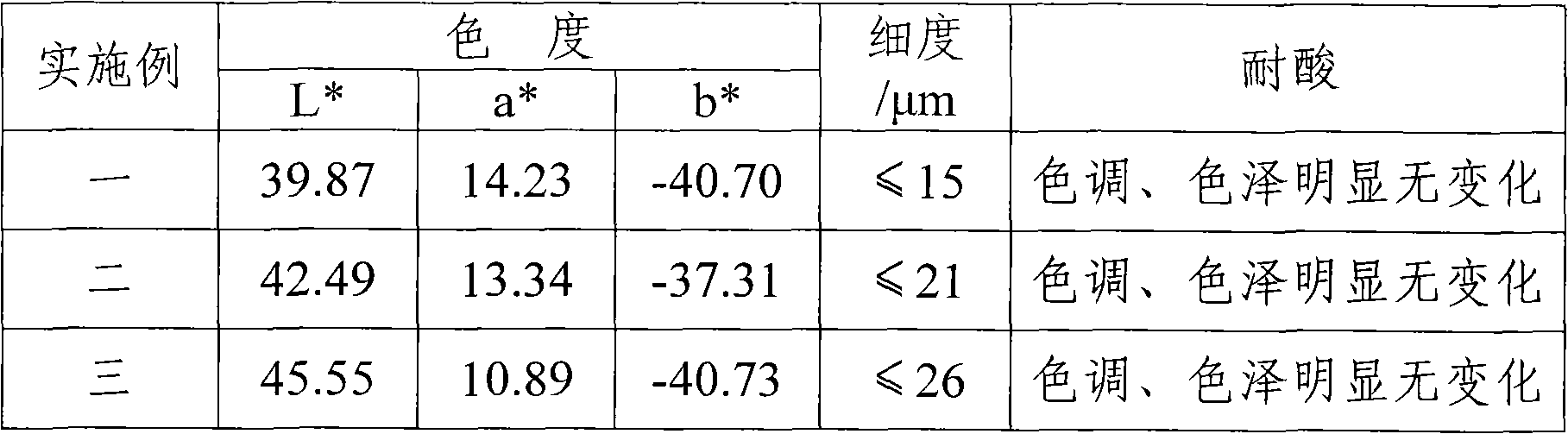

Examples

Embodiment 1-3

[0012] The first step: according to the formula of the crystal nucleating agent shown in Table 1, use distilled water to make the aqueous solution of the mixture respectively, stir it evenly, add 3mol / L sodium hydroxide solution, after the pH value of the solution is 13, mix it according to 60% Put the filling degree into a 100mL reactor, add the corresponding type and quantity of grain growth inhibitor, incubate in water for 20 hours at the corresponding temperature, take it out after cooling, rinse with distilled water at pH=7, and then dry at 80°C to obtain crystal nuclei .

[0013] Table 1: Mole Percentage (mol%)

[0014] Example

one

two

three

Cobalt Chloride (CoCl 2 ·6H 2 O)

20.0

25.0

32.0

Aluminum Chloride (AlCl 3 )

13.3

26.6

33.3

Cobalt Sulfate (CoSO 4 ·7H 2 O)

26.7

18.4

9.7

Aluminum Sulfate (Al 2 (SO 4 ) 3 18H 2 O)

40.0

30.0

25.0

Hydroth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com