Extraction method of fructus-clausenae-lanii-peel uranidin

An extraction method, yellow pigment technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of less research on the extraction of yellow peel pigments, achieve loose particles, short extraction time, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for extracting yellow pigment from yellow peel, comprising the following steps:

[0029] 1) Take the peel of the yellow skin, wash it, and crush it;

[0030] 2) Add distilled water to the crushed yellow peel, the ratio of solid to liquid is 1:60 (g / mL), place it at a low temperature of -15°C until it is completely frozen, then take it out and melt it at room temperature, add 0.6% cellulase, and Enzyme hydrolysis at 40°C for 35 minutes;

[0031] 3) centrifuging and discarding the precipitated part of impurities to obtain the yellow pigment crude extract of the yellow peel;

[0032] 4) passing the yellow pigment crude extract of the yellow peel of the yellow skin through a 100nm microfiltration membrane to obtain the primary effluent;

[0033] 5) passing the primary effluent through an ultrafiltration membrane with a molecular weight cut-off of 5KDa to obtain the final effluent;

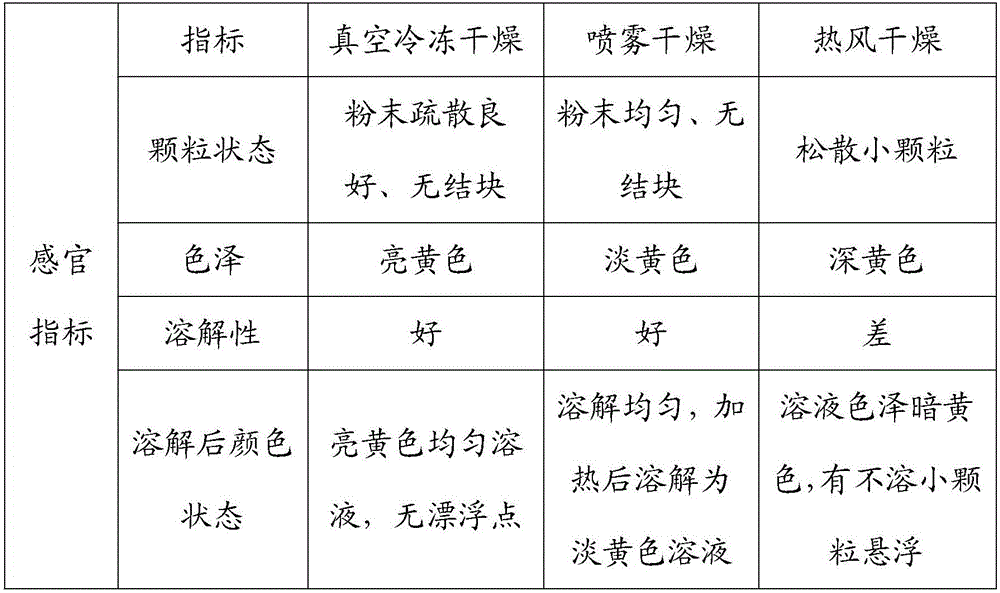

[0034] 6) Vacuum freeze-drying the final effluent to obtain the yellow pigment o...

Embodiment 2

[0038] A method for extracting yellow pigment from yellow peel, comprising the following steps:

[0039] 1) Take the peel of the yellow skin, wash it, and crush it;

[0040] 2) Add distilled water to the crushed yellow peel, the ratio of solid to liquid is 1:80 (g / mL), and place it in a low temperature -20°C to freeze until it is completely frozen, then take it out and melt it at room temperature, add 0.8% cellulase, and Enzyme hydrolysis at 50°C for 25 minutes;

[0041] 3) centrifuging and discarding the precipitated part of impurities to obtain the yellow pigment crude extract of the yellow peel;

[0042] 4) passing the yellow pigment crude extract of the yellow peel of the yellow skin through a 200nm microfiltration membrane to obtain the primary effluent;

[0043] 5) passing the primary effluent through an ultrafiltration membrane with a molecular weight cut-off of 3KDa to obtain the final effluent;

[0044] 6) Vacuum freeze-drying the final effluent to obtain the yello...

Embodiment 3

[0047] A method for extracting yellow pigment from yellow peel, comprising the following steps:

[0048] 1) Take the peel of the yellow skin, wash it, and crush it;

[0049] 2) Add distilled water to the pulverized yellow peel, the ratio of solid to liquid is 1:100 (g / mL), place it in the low temperature -18 ℃ and freeze until it is completely frozen, then take it out and melt it at room temperature, add 1.0% cellulase, and Enzyme hydrolysis at 55°C for 20 minutes;

[0050] 3) centrifuging and discarding the precipitated part of impurities to obtain the yellow pigment crude extract of the yellow peel;

[0051] 4) passing the yellow pigment crude extract of the yellow peel of the yellow skin through a 150nm microfiltration membrane to obtain the primary effluent;

[0052] 5) passing the primary effluent through an ultrafiltration membrane with a molecular weight cut-off of 4KDa to obtain the final effluent;

[0053] 6) Vacuum freeze-drying the final effluent to obtain the ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com