Preparation method of cobalt blue and clay mineral hybrid pigment

A technology of clay minerals and hybridization, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of easy mixing of impurities, small particle size of pigments, hard powder agglomeration, etc., and achieve low cost of raw materials and excellent color Bright, anti-agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

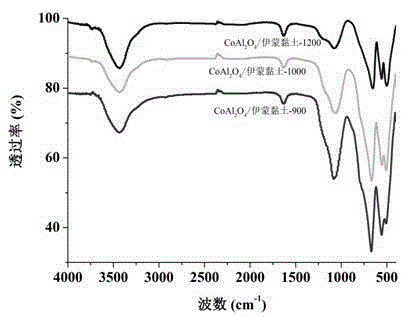

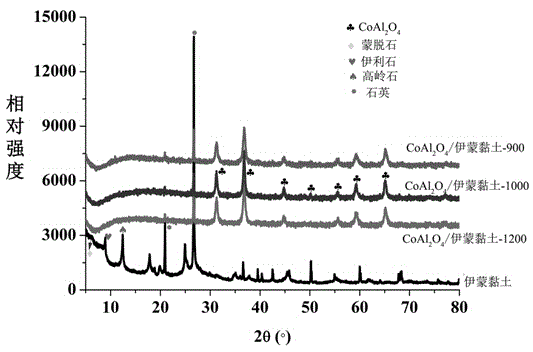

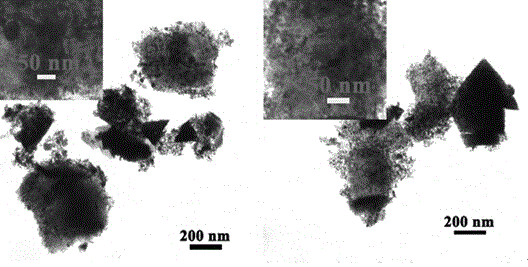

[0028] Add 0.8g of Imon clay into 50mL of water, stir, ultrasonically disperse to form a suspension, and then add 7.501g of Al(NO3 ) 3 and 2.91gCo(NO 3 ) 2 Stir to dissolve, slowly drop 3M NaOH until the pH of the system is 9, react at room temperature for 1 hour, centrifuge, wash until neutral, and dry at 70°C for 24 hours to obtain a pink powder; finally put the pink powder in a muffle furnace and calcinate at 900°C 2h (heating rate is 10oC / min), the obtained sample is marked as CoAl 2 o 4 / Emon Clay-900, the color is dark green.

Embodiment 2

[0030] The calcination temperature is 1000° C., and the others are the same as in Example 1. The resulting hybrid pigment is labeled CoAl 2 o 4 / Aemon's Clay - 1000, the color is bright blue.

Embodiment 3

[0032] The calcination temperature is 1200° C., and the others are the same as in Example 1. The resulting hybrid pigment is labeled CoAl 2 o 4 / Aemon's Clay - 1200, bright dark blue in color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com