Polyether ether ketone and its preparation method

A polyetheretherketone and fluoroketone technology, applied in the field of polyetheretherketone and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

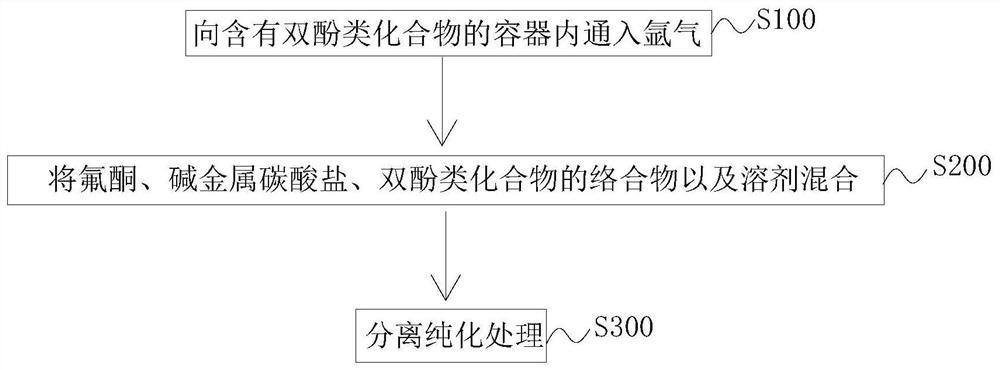

Method used

Image

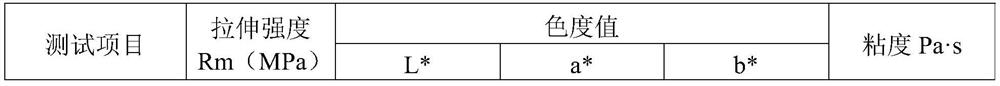

Examples

Embodiment 1

[0064] Add 300g of hydroquinone to a 500ml four-necked bottle, insert a stirring paddle into the middle port of the four-necked bottle, insert a tee pipe into one side port, connect the thermometer and argon gas inlet respectively to the three-way pipe, and insert a side port into The ventilation pipe is connected to the bottom of the four-necked bottle, and one side port is connected with a spherical condenser as an exhaust port. Put the four-necked bottle into the electric heating mantle, and pass high-purity argon gas into the four-necked bottle from the two inlet ports. The flow rate of argon gas is 50ml / min, and the purity of argon gas is ≥99.999%. Turn on the heating until the hydroquinone melts, adjust the argon gas flow to 200ml / min, start the stirring speed to 80rpm, maintain the temperature of the molten hydroquinone at 178°C, and continue the reaction for 1 hour. Put the four-neck bottle into a hot oil bath and cool to room temperature, turn off the argon to obtain ...

Embodiment 2

[0067]Add 300g of hydroquinone to a 500ml four-necked bottle, insert a stirring paddle into the middle port of the four-necked bottle, insert a tee pipe into one side port, connect the thermometer and argon gas inlet respectively to the three-way pipe, and insert a side port into The ventilation pipe is connected to the bottom of the four-necked bottle, and one side port is connected with a spherical condenser as an exhaust port. Put the four-necked bottle into the electric heating mantle, and pass high-purity argon gas into the four-necked bottle from the two inlet ports. The flow rate of argon gas is 50ml / min, and the purity of argon gas is ≥99.999%. Turn on the heating until the hydroquinone melts, adjust the argon gas flow rate to 200ml / min, start the stirring speed to 80rpm, maintain the temperature of the molten hydroquinone liquid at 188°C, and continue the reaction for 1 hour. Put the four-neck bottle into a hot oil bath to cool to room temperature, turn off the argon ...

Embodiment 3

[0070] Add 300g of hydroquinone to a 500ml four-necked bottle, insert a stirring paddle into the middle port of the four-necked bottle, insert a tee pipe into one side port, connect the thermometer and argon gas inlet respectively to the three-way pipe, and insert a side port into The ventilation pipe is connected to the bottom of the four-necked bottle, and one side port is connected with a spherical condenser as an exhaust port. Put the four-necked bottle into the electric heating mantle, and pass high-purity argon gas into the four-necked bottle from the two inlet ports. The flow rate of argon gas is 50ml / min, and the purity of argon gas is ≥99.999%. Turn on the heating until the hydroquinone melts, adjust the argon gas flow to 200ml / min, start the stirring speed to 80rpm, maintain the temperature of the molten hydroquinone at 198°C, and continue the reaction for 1 hour. Put the four-neck bottle into a hot oil bath to cool to room temperature, turn off the argon to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com