Preparation method for FeS2 pyrite microballoon sphere and application thereof

A technology of pyrite and microspheres, applied in the field of nanomaterials, can solve the problems of complex process, uneven morphology, impure product phase, etc., and achieve the effect of simple process, excellent electrical and optical properties, and good monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

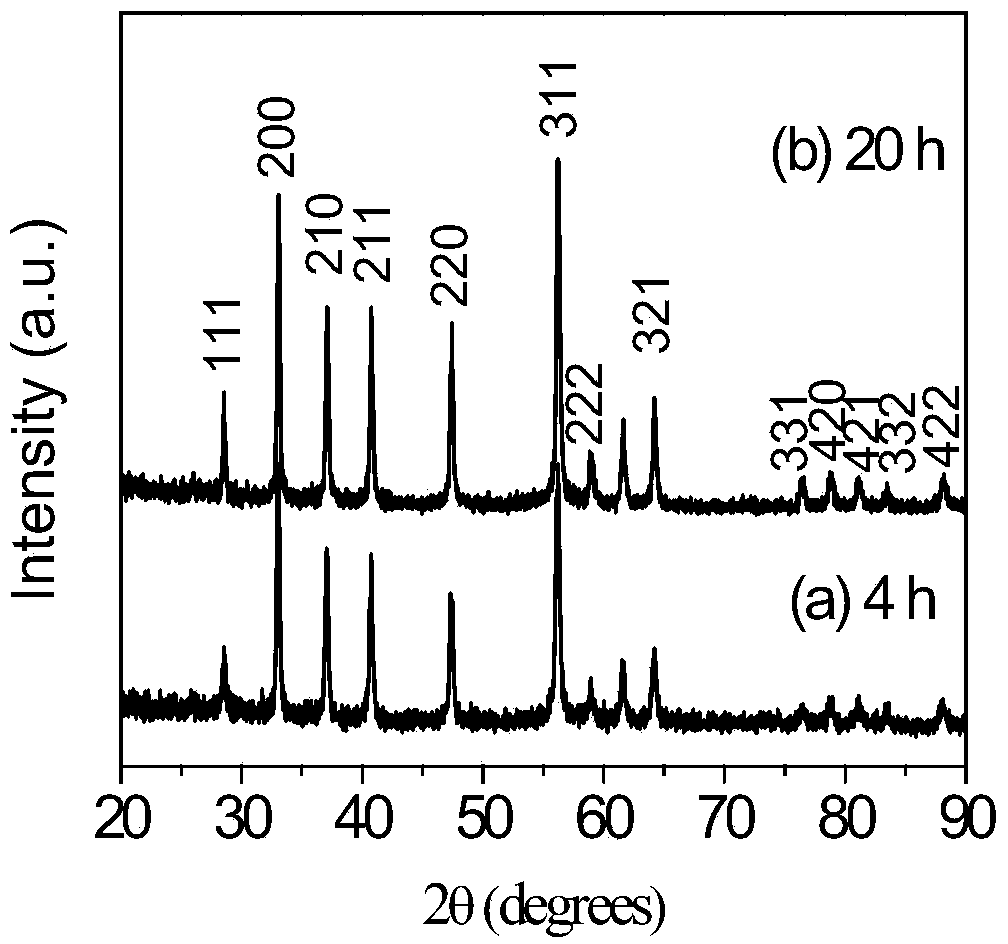

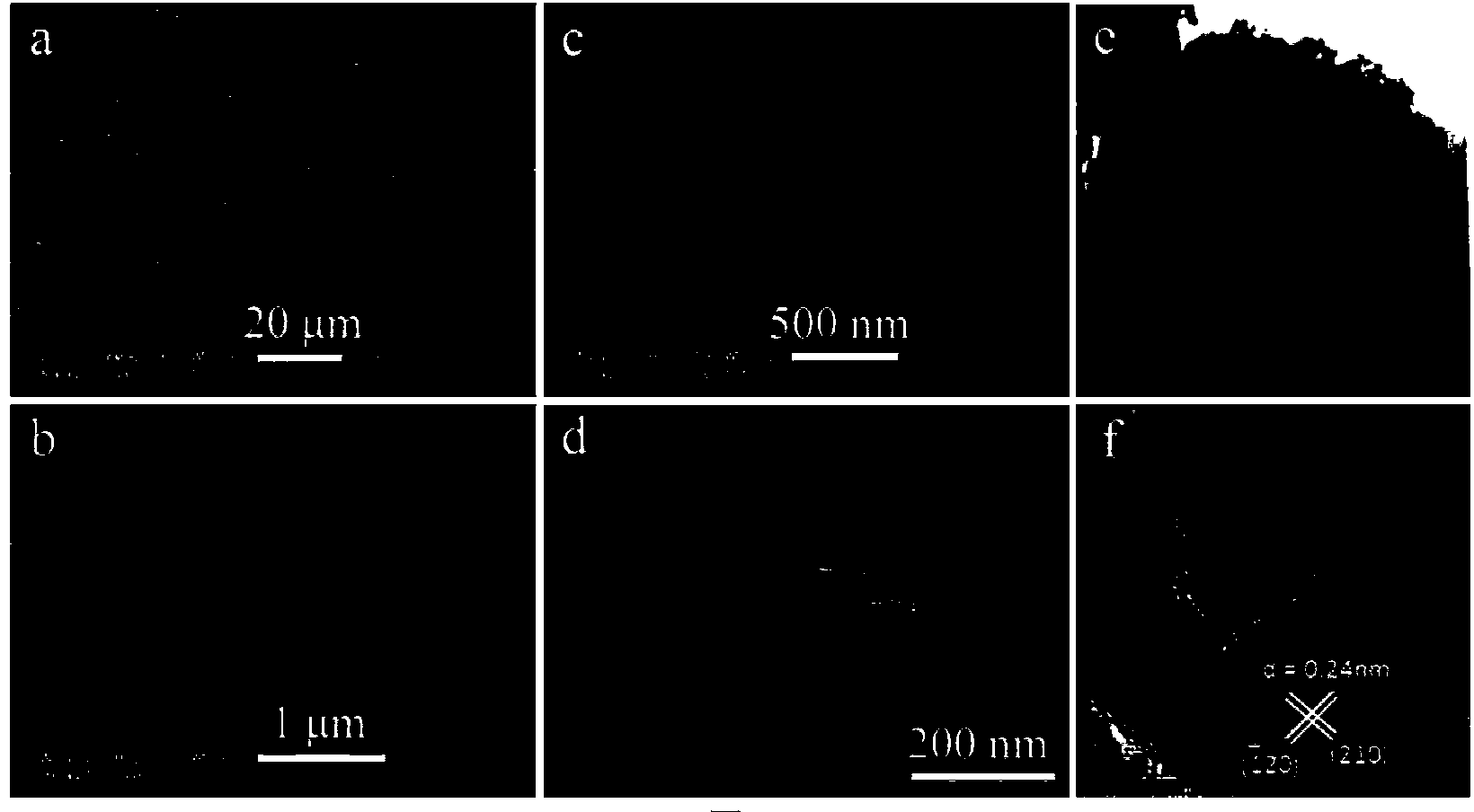

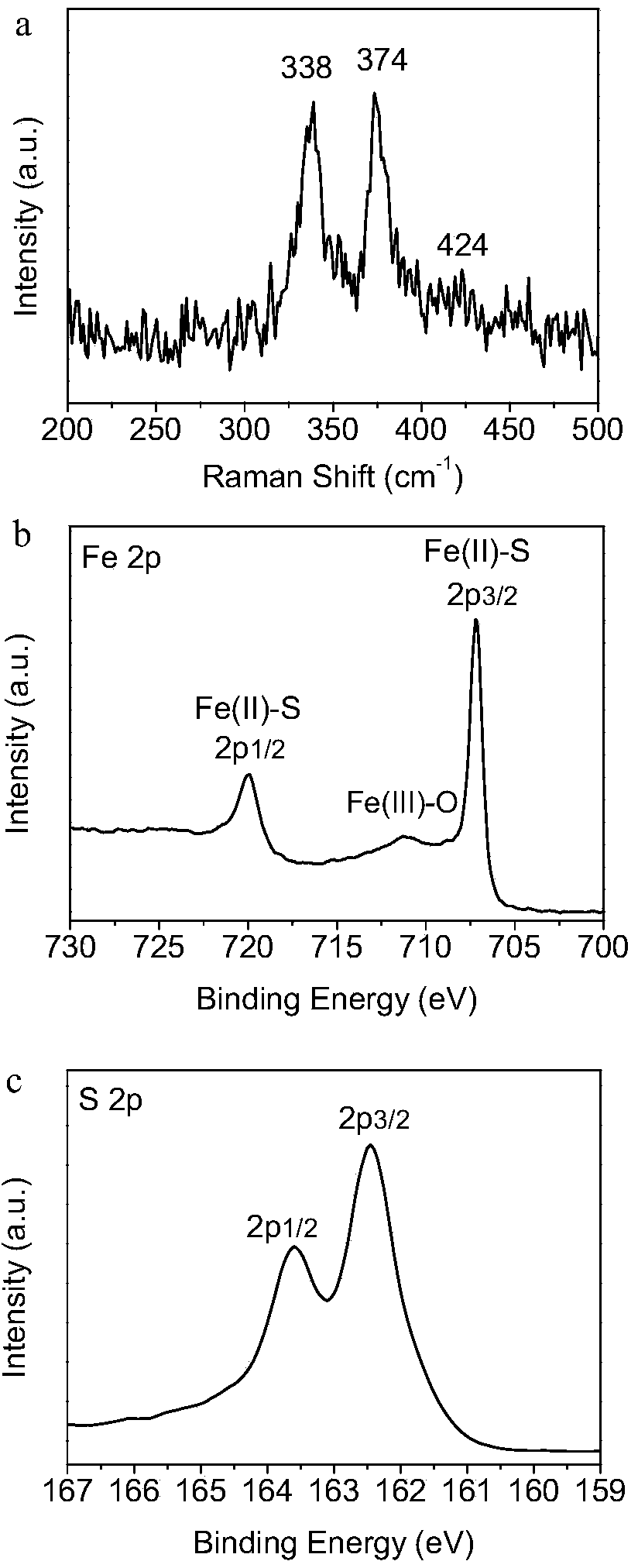

[0031] This embodiment prepares FeS according to the following steps 2 Pyrite microspheres:

[0032] a. Weigh or measure each raw material according to Table 1: S powder is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), analytically pure (>99.9%); FeSO 4 ·7H 2 O is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), analytically pure (>99.5%); triethylene glycol is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), chemically pure (>98%);

[0033] Table 1

[0034] Example

S powder

FeSO 4 ·7H 2 o

temperature

time

1

1.25mmol

0.5mmol

40ml

200℃

4h

2

1.25mmol

0.5mmol

40ml

200℃

6h

3

1.25mmol

0.5mmol

40ml

200℃

10h

4

1.25mmol

0.5mmol

40ml

200℃

20h

[0035] b. FeSO 4 ·7H 2 O was dissolved in triethylene glycol, and 1.25 mmol of sulfur powder was added, magnetically stirred for 10 minut...

Embodiment 5

[0039] This embodiment prepares FeS according to the following steps 2 Pyrite microspheres:

[0040] a. Weigh or measure each raw material according to Table 2: wherein S powder is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), analytically pure (>99.9%); FeCl 2 4H 2 O is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), analytically pure (>99.5%); triethylene glycol is selected from (Shanghai Runjie Chemical Reagent Co., Ltd.), chemically pure (>98%);

[0041] Table 2

[0042] Example

S powder

FeCl 2 4H 2 o

triethylene glycol

temperature

time

5

1.25mmol

0.5mmol

40ml

170℃

10h

[0043] b. FeCl 2 4H 2 O was dissolved in triethylene glycol, and 1.25 mmol of sulfur powder was added, magnetically stirred for 10 minutes and then ultrasonically treated for 20 minutes to fully disperse the sulfur powder to obtain a mixed solution.

[0044] c. Then transfer the obtained mixed solution to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com