Preparation method for niobium/tantalum cation disordered rock salt structure anode material

A cathode material and cation technology, applied in the field of preparation of cathode materials containing niobium/tantalum cation disordered rock salt structure, can solve the problems of expensive niobium salt, easy hydrolysis, easy introduction of impurities, etc. The effect of a simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

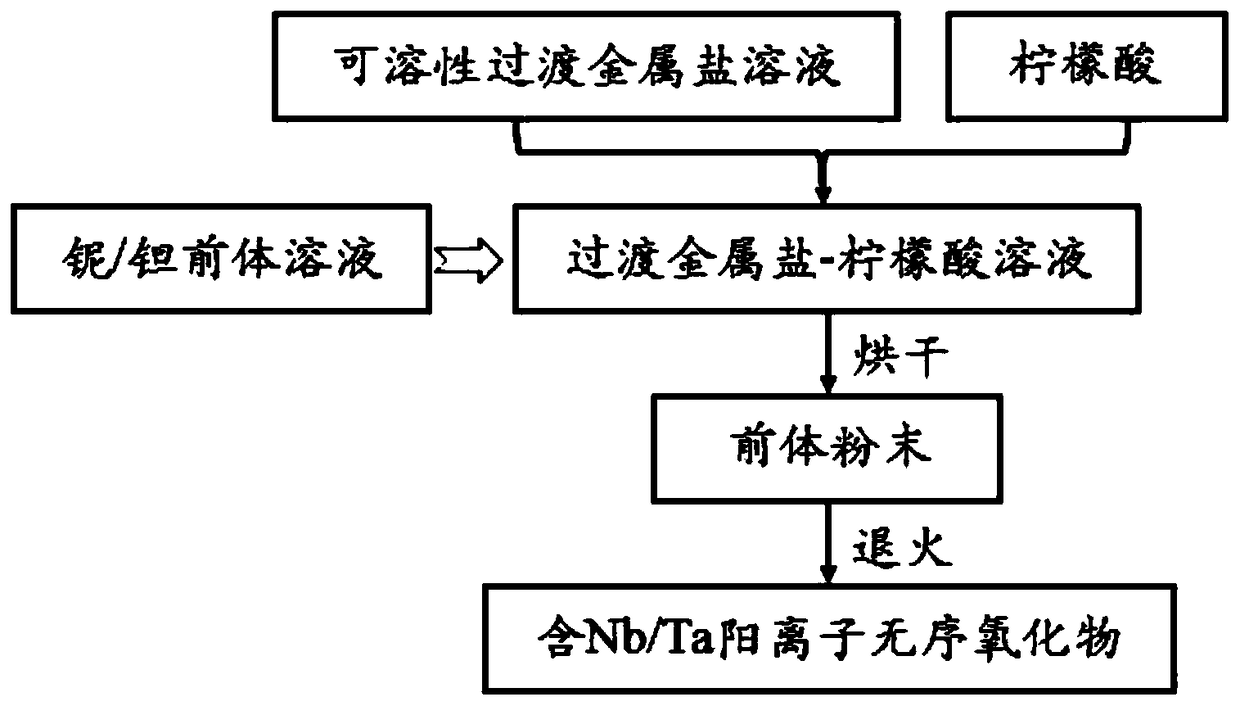

[0031] The preparation embodiment of cathode material (concrete preparation process is as figure 1 shown):

[0032] Synthetic raw materials: niobium / tantalum citrate precursor solution, soluble nickel salt (analytical pure), soluble cobalt salt (analytical pure), soluble manganese salt (analytical pure), citric acid (analytical pure), deionized water.

Embodiment 1

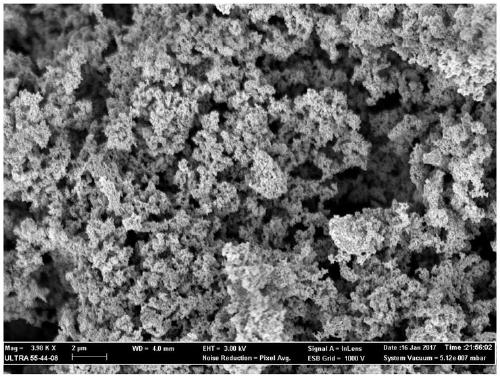

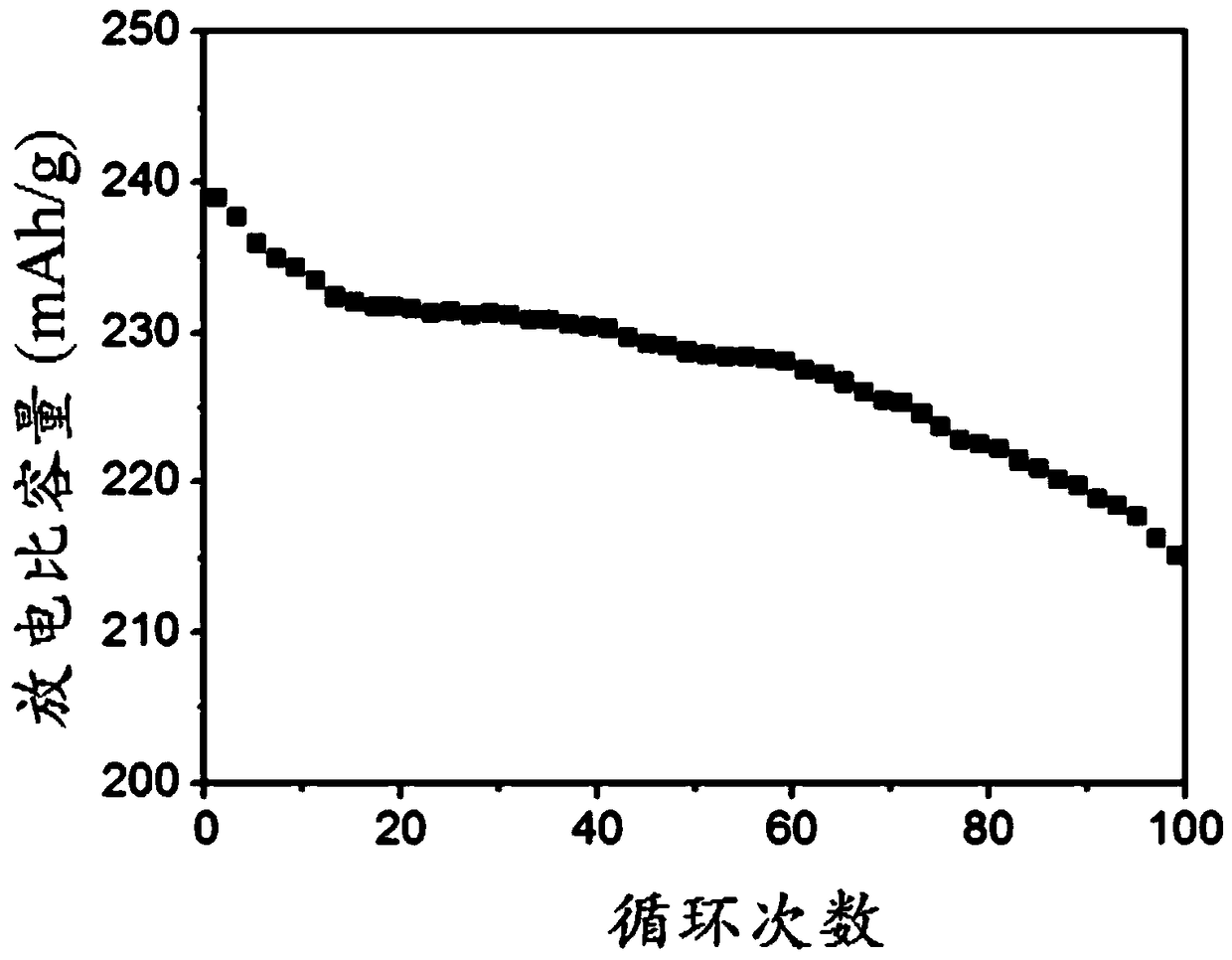

[0034] Prepare a manganese nitrate solution with a cation concentration of 1.5mol / L, add an appropriate amount of citric acid, and the molar ratio of metal manganese ions to citric acid is 1:1. An appropriate amount of water-soluble niobium citrate precursor solution is added so that the molar ratio of niobium ions to transition manganese metal ions is Nb:TM=1:1.3. The above solution was evaporated to dryness by heating at 90° C., and then dried at 150° C. for 12 hours to form a powder precursor; the powder precursor was pretreated at 350° C. for 2.0 hours. After mixing the pre-calcined powder with an appropriate amount of lithium salt, the amount of lithium salt should be added in excess of 5wt.%. Using ethanol as the medium, ball mill for 6 hours at a speed of 500r / min. After drying and compacting, it was annealed at 850 °C for 12 hours in an Ar atmosphere in a tube furnace to obtain Li 1.3 Nb 0.3 mn 0.4 o 2 Cationic disordered oxide powder samples. The oxide material i...

Embodiment 2

[0036] Prepare a cobalt nitrate solution with a cation concentration of 0.2mol / L, add an appropriate amount of citric acid, and the molar ratio of metal cobalt ions to citric acid is 1:0.5. An appropriate amount of water-soluble niobium citrate precursor solution is added so that the molar ratio of niobium ions to metal cobalt ions is Nb:TM=1:0.5. The above solution was evaporated to dryness by heating at 70° C., and then dried at 100° C. for 24 hours to form a powder precursor; the powder precursor was pretreated at 300° C. for 3.0 hours. After the pre-calcined powder is mixed with an appropriate amount of lithium salt, the amount of lithium salt should be added in excess of 10wt.%. Using ethanol as the medium, ball mill at 300r / min for 12 hours. After drying and compacting, in a tube furnace N 2 Annealing at 1000°C for 6 hours under atmospheric conditions yields Li 1.25 Nb 0.5 co 0.25 o 2 Cationic disordered oxide powder samples. The oxide material is used as the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com