Method for directly synthesizing M-phase vanadium dioxide nano particles by liquid phase method

A technology of vanadium dioxide nanometer and liquid phase method, which is applied in the field of preparation of functional inorganic materials, can solve the problems of large particle size of M-phase VO2, high preparation cost, complicated process, etc., achieve significant competitive advantages and profit margins, and mild production conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

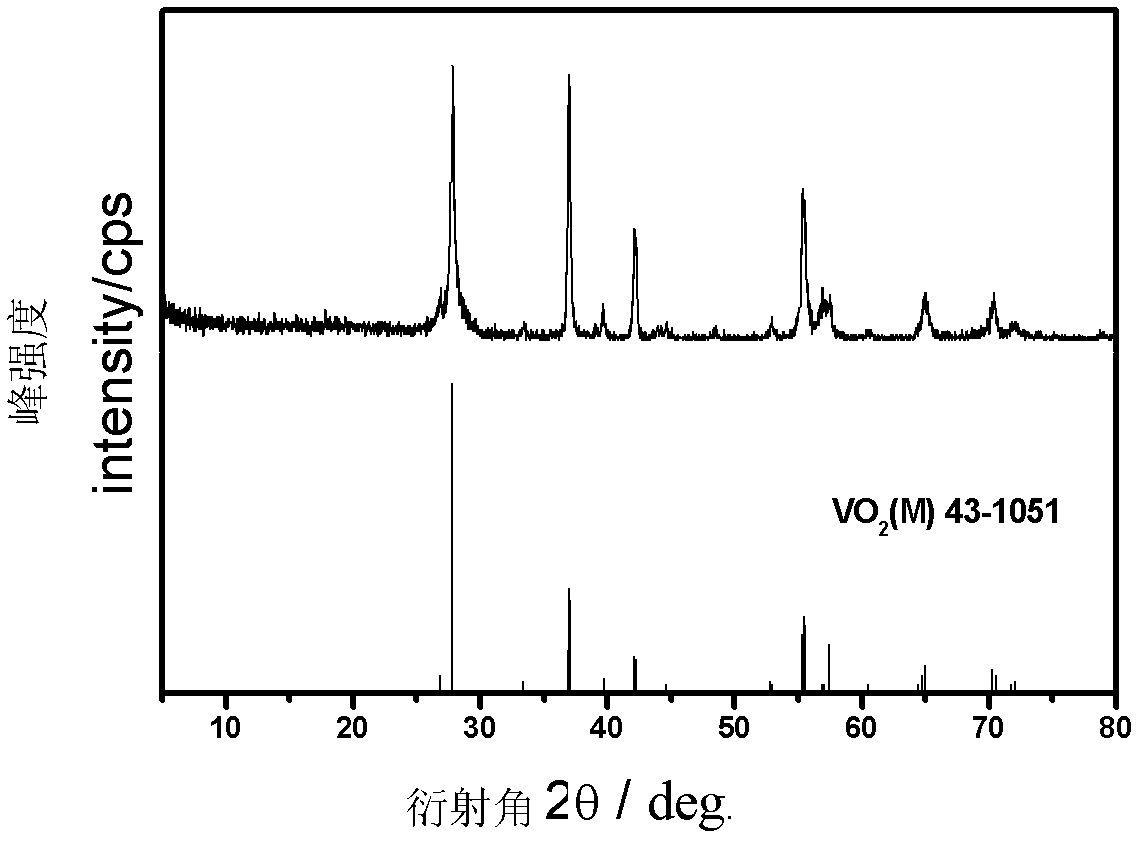

Embodiment 1

[0015] Take 0.3637g of vanadium pentoxide and 30-60mL of distilled water on a heating magnetic stirrer (60-100°C, 450-1100r / min) and mix for 10-30min to form a uniform suspension; then add 4mL of the prepared hydrazine hydrochloride solution ( V: hydrazine hydrochloride=1: 3) is slowly added dropwise in the vanadium pentoxide suspension that mixes homogeneously, continues reaction 1~6 hour, uses hydrochloric acid to regulate pH value in the reaction process and remains in the scope of 1~3; The reaction product is subjected to centrifugation (8000-12000 rad / min, 10-15 min) to obtain a precipitate of the reaction precursor. Mix the precursor precipitate with 50mL of distilled water and transfer it to a reaction steel kettle with a polytetrafluoroethylene liner. After the filling rate is 60-70%, the reaction temperature is 240°C, and the reaction time is 36h, it is cooled at room temperature and centrifuged (8000~ 12000rad / min, 10~15min), washing (washing with distilled water and...

Embodiment 2

[0017] Take 0.3637g of vanadium pentoxide and 30-70mL of distilled water on a heating magnetic stirrer (60-100°C, 450-1100r / min) and mix for 20-30min to form a uniform suspension; then add 10mL of the prepared oxalic acid solution (V : oxalic acid=1: 2) is slowly added dropwise in the mixed ammonium metavanadate solution, adjusts pH to be 2~3 with sulfuric acid solution, continues reaction 1~3 hour; Reaction product is carried out centrifugation (8000~12000rad / min, 10-15min) to obtain the precipitation of the reaction precursor. Mix the precursor precipitate with 70mL of distilled water and transfer it to a reaction steel kettle with a polytetrafluoroethylene liner. After the filling rate is 60-70%, the reaction temperature is 260°C, and the reaction time is 48 hours, it is cooled at room temperature and centrifuged (8000~ 12000rad / min, 10~15min), washing (washing with distilled water and absolute ethanol for 2~4 times respectively), drying (temperature not higher than 100°C,...

Embodiment 3

[0019] Take 0.4680g of ammonium metavanadate and 10-40mL of distilled water on a heated magnetic stirrer (60-120°C, 450-1100r / min) and mix for 20-30min to form a uniform suspension; then mix 5mL of the prepared hydrazine hydrate solution ( V: hydrazine hydrate = 1: 1) is slowly added dropwise in the uniformly mixed ammonium metavanadate solution, and the pH is adjusted to about 3 with hydrochloric acid, and the reaction is continued for 4 to 6 hours; the reaction product is centrifuged (8000 to 12000 rad / min, 10-15min) to obtain the precipitation of the reaction precursor. Mix the precursor precipitate with 40mL of distilled water and transfer it to a reaction steel kettle with a polytetrafluoroethylene liner. After the filling rate is 70-80%, the reaction temperature is 220 ° C, and the reaction time is 24 hours, it is cooled at room temperature and centrifuged (8000~ 12000rad / min, 10~15min), washing (washing with distilled water and absolute ethanol for 2~4 times respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com