Polymerization forming prepn process of ternary lithium ceramic microsphere

A technology of ceramic microspheres and microspheres, which is applied in ceramic products, applications, household appliances, etc., and can solve problems such as poor particle size dispersion, difficult control of microsphere particle size, and poor sphericity of ceramic microspheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

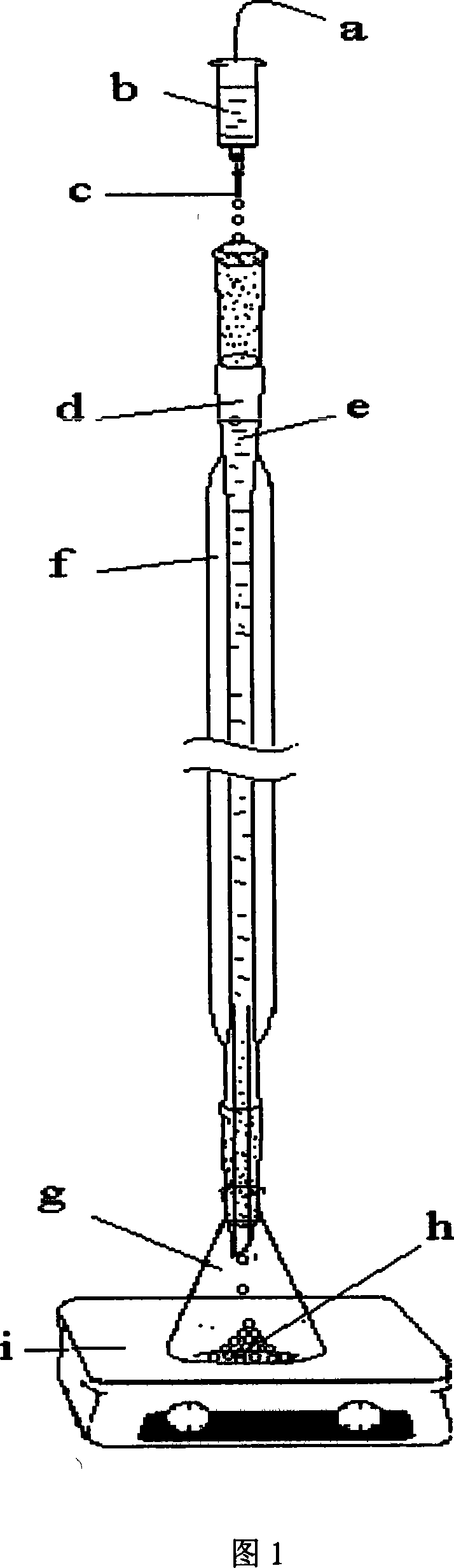

[0030]The preparation method of ternary lithium ceramic microspheres by polymerization and molding in the present invention comprises the following steps: (1) dissolving the raw materials for preparing ternary lithium ceramic microspheres, polymer monomers, crosslinking agents and auxiliary agents, etc. in a solvent to form A pasty mixture. The monomer is acrylamide, the crosslinking agent is methylenebisacrylamide, and the auxiliary agent is polyacrylamide. (2) Add defoamer to the pasty mixture and transfer it to a planetary grinder for 2 to 6 hours of grinding. After grinding, the mixture becomes a basically stable suspension slurry, in which the defoamer is isooctyl alcohol or fatty acid. (3) Add initiator and catalyst to the suspension slurry, stir quickly, transfer to the microsphere forming device, and form a bead-like liquid with a diameter of 1.0mm to 3.0mm through the nozzle under a certain pressure. , moving from top to bottom in a hydrophobic medium with a high vi...

Embodiment 1

[0033] (1) Dissolve 5g of acrylamide, 2g of polyacrylamide, and 0.5g of methylenebisacrylamide in 100g of water; (2) weigh Li 2 CO 3 and SiO 2 Powder 150g, add (1) the prepared solution and mix; (3) add 5 drops of isooctyl alcohol, and grind in a planetary mill for 5 hours to form a suspension slurry; (6) in the ground slurry Add 10 drops of 5% ammonium persulfate solution and 8 drops of tetramethylethylenediamine, stir evenly; (7) put the slurry into the microsphere preparation device shown in Figure 1, open the pressure control system, and the pressure is controlled at 20kPa, the slurry is sprayed from the nozzle, dripped into the heated silicone oil, and microspheres are formed due to the surface tension. Under the action of gravity, the crosslinking reaction occurs during the falling process of the microspheres and solidifies; (8) basically cured microspheres Drop into the microsphere collector and further react completely, the microsphere precursor of formation; (9) use...

Embodiment 2

[0035] (1) Dissolve 6g of acrylamide, 2g of polyacrylamide, and 0.5g of methylenebisacrylamide in 100g of water; (2) weigh Li 2 CO 3 and TiO 2 Powder 150g, add (1) prepared solution and mix; (3) add 8 drops of isooctyl alcohol, grind in planetary grinder for 6 hours to form ceramic slurry; (6) add 5 % ammonium persulfate solution 10 drops and 8 drops of tetramethylethylenediamine, stir; (7) slurry is packed in the microsphere preparation device shown in Figure 1, open pressure control system, pressure is controlled at 10kPa, The slurry is ejected from the nozzle and dripped into the heated silicone oil. Due to the surface tension, microspheres are formed. Under the action of gravity, the crosslinking reaction occurs during the falling process of the microspheres and solidifies; Further reaction is complete in the ball collector, the microsphere precursor of formation; (9) use CCl 4 Cleaning the fully reacted microsphere precursor; (10) aging the microsphere precursor at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com