Preparation method of aluminum-doped cobaltosic oxide

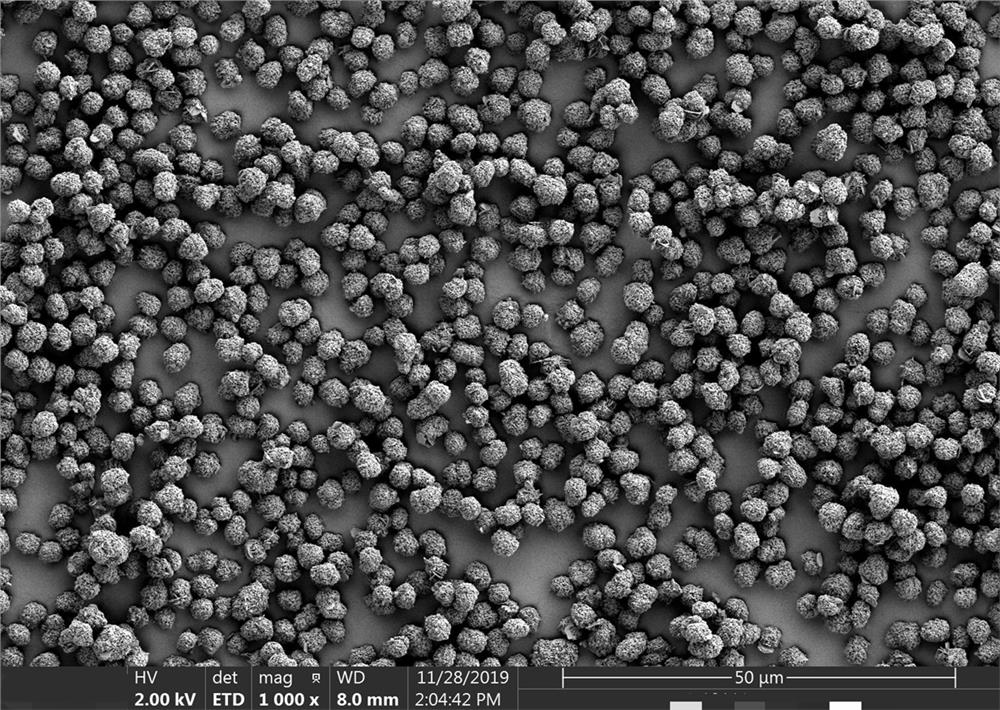

A technology of cobalt tetroxide and cobalt carbonate, which is applied in the field of preparation of aluminum-doped cobalt tetroxide, can solve problems such as unproposed solutions, and achieve the effect of uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of aluminum-doped cobalt tetroxide described in this embodiment, the specific steps are as follows:

[0032] Step 1. Prepare the solution: the concentration of the aluminum-doped cobalt sulfate solution is 2.4 mol / L, the mass ratio of aluminum-cobalt element in it is 0.014, and the concentration of the ammonium bicarbonate solution is 2.8 mol / L.

[0033] Step 2, crystal seed synthesis: inject pure water into the reaction kettle and add the low-concentration ammonium bicarbonate solution after mixing and diluting the ammonium bicarbonate solution in step 1 as the bottom liquid, the bottom liquid volume is 6%, and the ammonium bicarbonate concentration in the bottom liquid 40 g / L, the pH value of the bottom solution was controlled at 8.3. At a high stirring speed of 500rpm, the aluminum-cobalt solution and ammonium bicarbonate solution configured in step 1 are simultaneously pumped into the reactor in a certain proportion. The capacity is 16%...

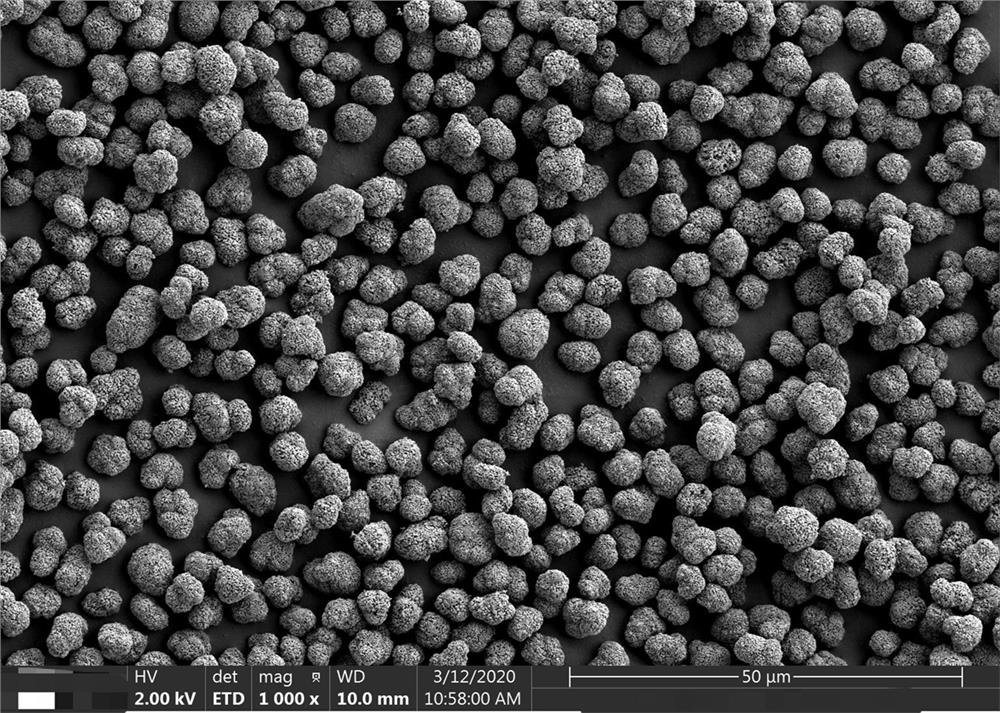

Embodiment 2

[0039] A kind of preparation method of aluminum-doped cobalt tetroxide described in this embodiment, the specific steps are as follows:

[0040] Step 1. Prepare the solution: the concentration of the aluminum-cobalt chloride solution is 2.2 mol / L, the mass ratio of the aluminum-cobalt element in it is 0.00972, and the concentration of the ammonium bicarbonate solution is 2.7 mol / L.

[0041]Step 2, crystal seed synthesis: Inject pure water into the reactor and add the low-concentration ammonium bicarbonate solution after mixing and diluting the ammonium bicarbonate solution in step 1 as the bottom liquid, the bottom liquid volume is 10%, and the ammonium bicarbonate concentration in the bottom liquid 30 g / L, and the pH value of the bottom solution was controlled at 8.0. At a high stirring speed of 400rpm, the aluminum-cobalt solution and ammonium bicarbonate solution configured in step 1 are simultaneously pumped into the reactor in a certain proportion. The capacity is 30%, t...

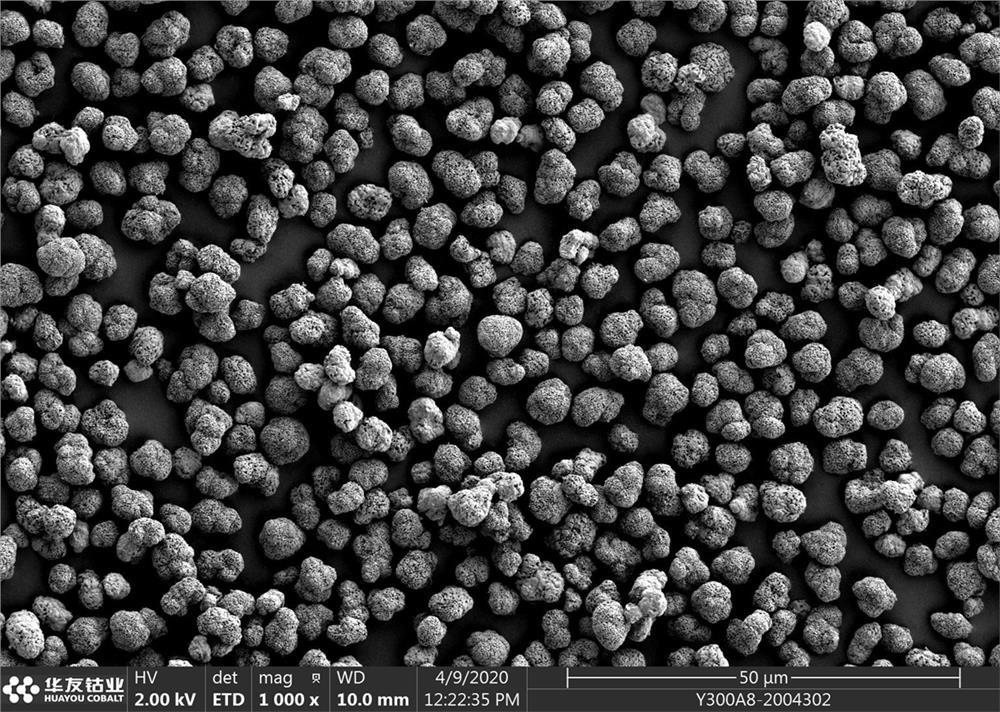

Embodiment 3

[0047] A kind of preparation method of aluminum-doped cobalt tetroxide described in this embodiment, the specific steps are as follows:

[0048] Step 1. Prepare the solution: the concentration of the aluminum-doped cobalt sulfate solution is 1.5 mol / L, the mass ratio of the aluminum-cobalt element in it is 0.0083, and the concentration of the ammonium bicarbonate solution is 2.5 mol / L.

[0049] Step 2. Synthesis of seed crystals: Inject pure water into the reaction kettle and mix and dilute the low-concentration ammonium bicarbonate solution in step 1 as the bottom liquid. The volume of the bottom liquid is 20%, and the concentration of ammonium bicarbonate in the bottom liquid is 20 g / L, the pH value of the bottom solution was controlled at 7.8. At a high stirring speed of 320 rpm, the aluminum-cobalt solution and ammonium bicarbonate solution configured in step 1 are simultaneously pumped into the reactor in a certain proportion, the molar ratio of cobalt salt and ammonium b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com