Polishing liquid, preparation method and application thereof

A polishing liquid and liquid technology, applied in the field of polishing liquid, can solve the problems of unstable performance of polishing liquid and short cycle life, and achieve the effect of reducing the time of cleaning the machine, reducing crystallization, and alleviating scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

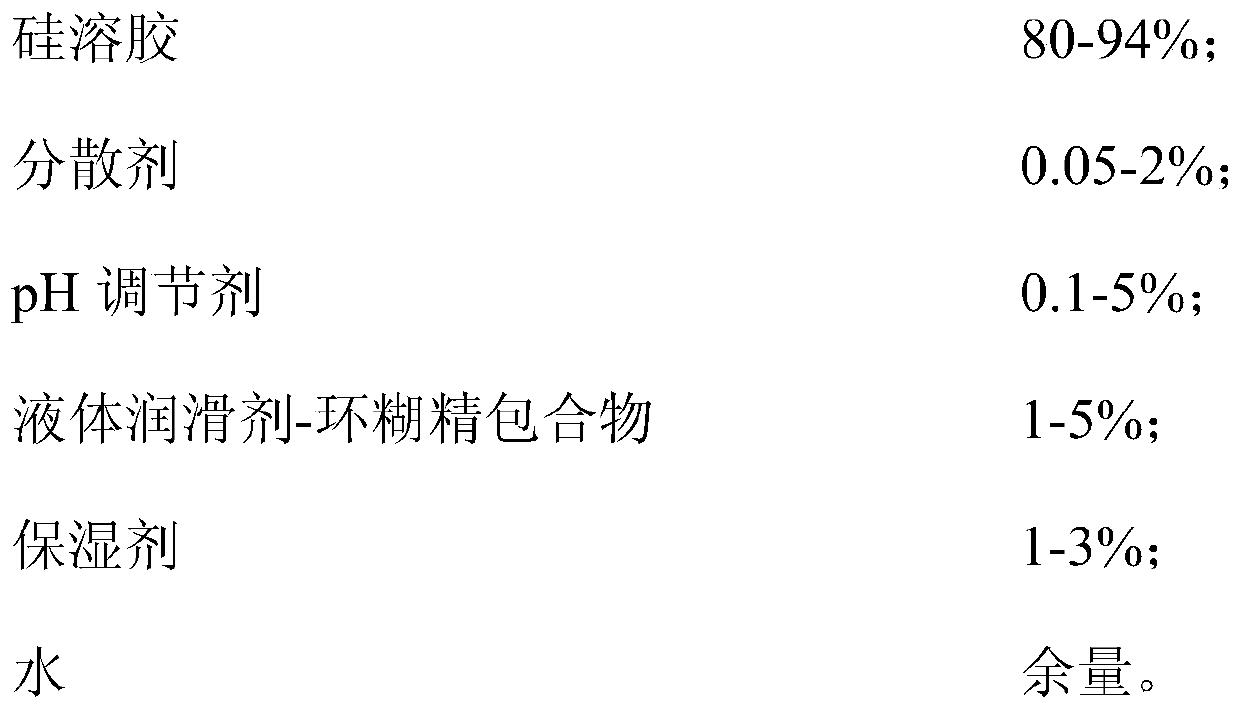

[0057] The present embodiment provides a kind of polishing liquid, and described polishing liquid comprises the following components by weight percentage:

[0058]

[0059] Wherein the particle diameter of silica in silica sol is 120nm, and the solid capacity of silica in silica sol is 40%; Dispersant is polyethylene glycol 400; pH adjuster is potassium hydroxide, ethylenediamine and triethanolamine Combination, the mass ratio of potassium hydroxide, ethylenediamine and triethanolamine is 1:1:1; the humectant is butanediol; the mass ratio of liquid lubricant and cyclodextrin in the liquid lubricant-cyclodextrin inclusion compound 1:3, the liquid lubricant is a combination of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether, the mass ratio of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether is 1:1; liquid lubrication The preparation method of agent-cyclodextrin clathrate comprises: adding fatty alcohol polyoxyethylene ether a...

Embodiment 2

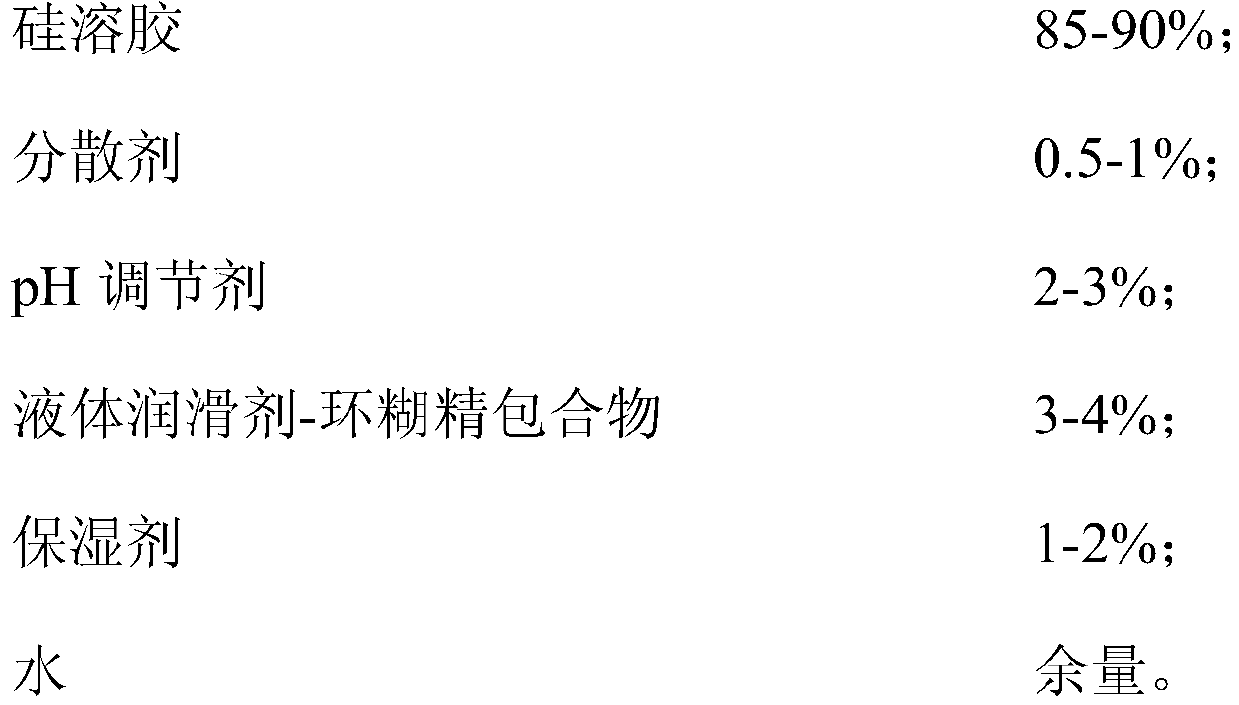

[0064] The present embodiment provides a kind of polishing liquid, and described polishing liquid comprises the following components by weight percentage:

[0065]

[0066] Wherein the particle diameter of silicon dioxide in the silica sol is 80nm, and the solid capacity of silicon dioxide in the silica sol is 50%; the dispersant is sodium citrate; the pH regulator is a combination of potassium hydroxide, ethylenediamine and triethanolamine, The mass ratio of potassium hydroxide, ethylenediamine and triethanolamine is 1:1:1; the moisturizing agent is glycerol; the mass ratio of liquid lubricant and cyclodextrin in the liquid lubricant-cyclodextrin inclusion compound is 1 : 1, the liquid lubricant is a combination of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether, the mass ratio of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether is 3:1; liquid lubricant- The preparation method of the cyclodextrin inclusion compound compris...

Embodiment 3

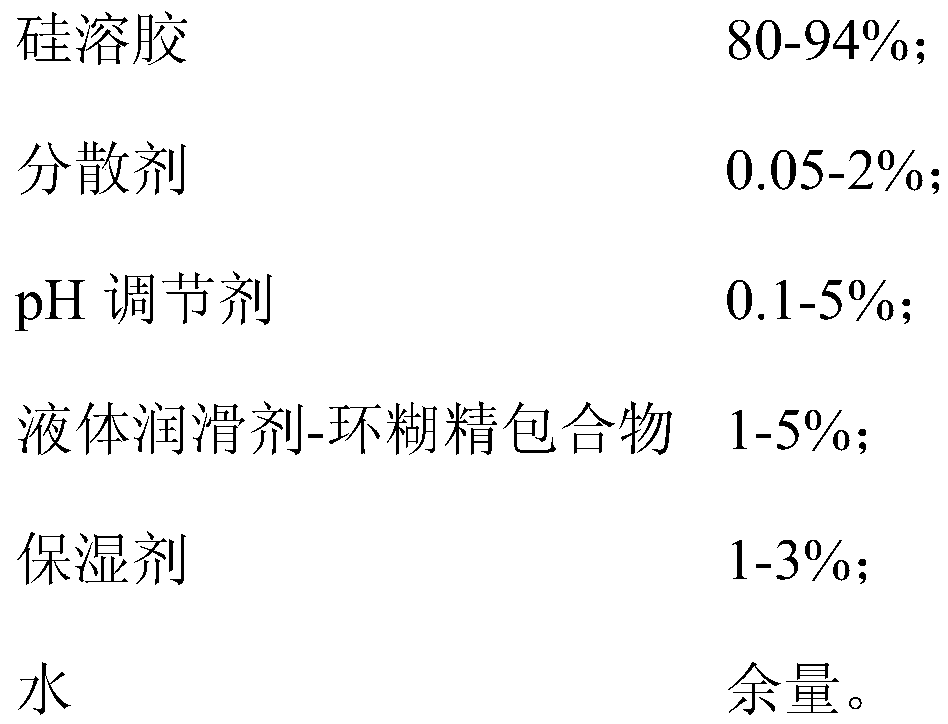

[0071] The present embodiment provides a kind of polishing liquid, and described polishing liquid comprises the following components by weight percentage:

[0072]

[0073] Wherein the particle diameter of silicon dioxide in the silica sol is 150nm, and the solid capacity of silicon dioxide in the silica sol is 30%; the dispersant is sodium orthophosphate; the pH regulator is a combination of potassium hydroxide, ethylenediamine and triethanolamine, The mass ratio of potassium hydroxide, ethylenediamine and triethanolamine is 1:1:1; the moisturizing agent is propylene glycol; the mass ratio of liquid lubricant and cyclodextrin in the liquid lubricant-cyclodextrin inclusion compound is 1:5 , the liquid lubricant is a combination of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether, the mass ratio of fatty alcohol polyoxyethylene ether and nonylphenol polyoxyethylene ether is 2:1; liquid lubricant-cyclopaste The preparation method of the fine clathrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com