Hydroscopic fine denier/superfine denier chinlon master batch, chinlon POY filaments and preparation method thereof

A fine-denier nylon and hygroscopicity technology, which is applied in the field of spinning materials, can solve the problems of unspecified nylon fiber specifications, large amount of moisture-absorbing modifier, and difficult practical operation, etc., to improve dyeing performance, improve mixing performance, and improve moisture absorption. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

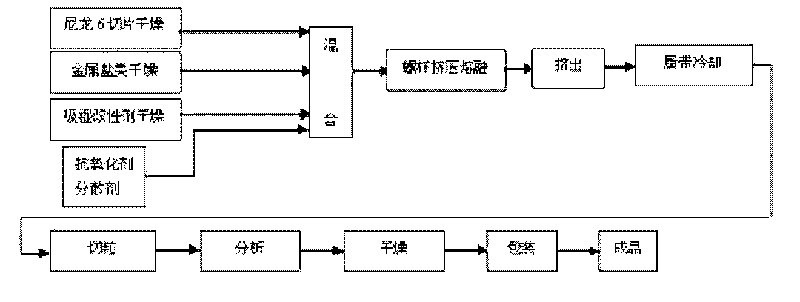

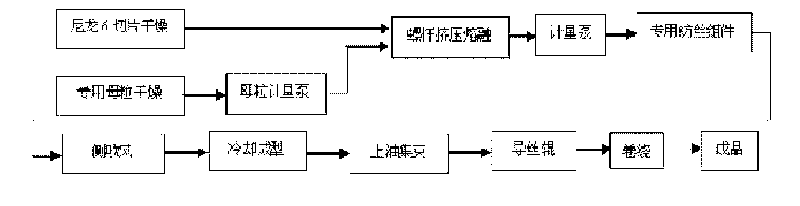

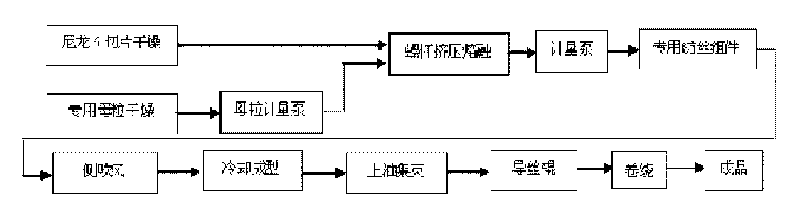

Method used

Image

Examples

Embodiment 1

[0065] (1) Raw materials: In terms of the weight of nylon 6 slices, weigh 1.0% of its weight PVP (PVP10000 and PVP24000 mass ratio is a mixture of 2: 1), 0.8% of MgSO 4 , 0.2% of antioxidant (antioxidant 1010 and antioxidant 168, the ratio of the two is 1:1), 0.2% of dispersant (liquid paraffin and PEG600, the ratio of the two is 1:1).

Embodiment 2

[0068] The vacuum-dried nylon 6 slices (moisture content 580ppm) and hygroscopic fine denier / ultrafine denier nylon masterbatch (moisture content 850ppm) are transported to the twin-screw high-speed spinning machine, and the supply volume of the nylon slice pump is 86.4g / min , the flow rate of the masterbatch pump is 1.32g / min, when the melt spinning temperature is 281°C, the screw speed is 25r / min and the screw pressure is 90-110kg / cm 2 Next, the molten mixture is extruded by a screw (including static and dynamic mixers), pumped into the spinneret assembly by metering, filtered by sea sand, and then passed through the spinneret hole (the spinneret hole is characterized by a diameter of 0.3mm, Aspect ratio 2.7) extrusion. Then, in the spinneret ring air blowing device, the temperature of the blown air is 36°C, the humidity is 50%, and the wind speed is 0.3m / s. Next, the fibers cooled by side blowing are bundled and oiled through an oil mist nozzle, and the oiling rate is 0.9 ...

Embodiment 3

[0070] (1) Raw materials: by weight of nylon 6 slices, weigh 2.4% of its weight PVP (the mixture of PVP10000 and PVP24000 with a mass ratio of 2:1), 3% of Zn(Ac) 2 , 0.5% of antioxidant (antioxidant 1010 and antioxidant 168, the ratio of the two is 1:1), 0.4% of dispersant (liquid paraffin and PEG600, the ratio of the two is 1:1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com