Method for preparing bottle-grade slices by recycling waste polyester bottles

A technology of waste polyester and polyester bottles, which is applied in recycling technology, plastic recycling, etc., can solve problems such as difficult common mixing and processing, achieve stable melt molecular weight distribution, adjust the amount of recycled waste polyester bottles, and improve The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

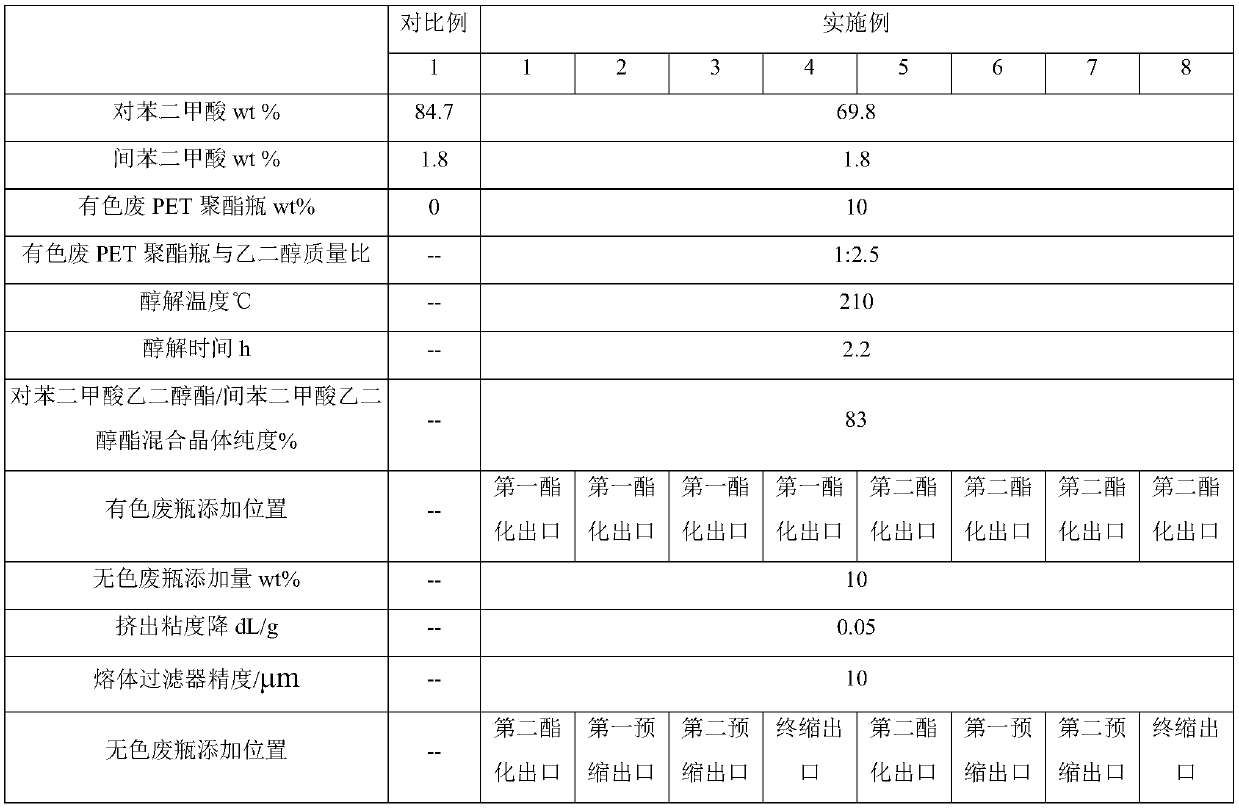

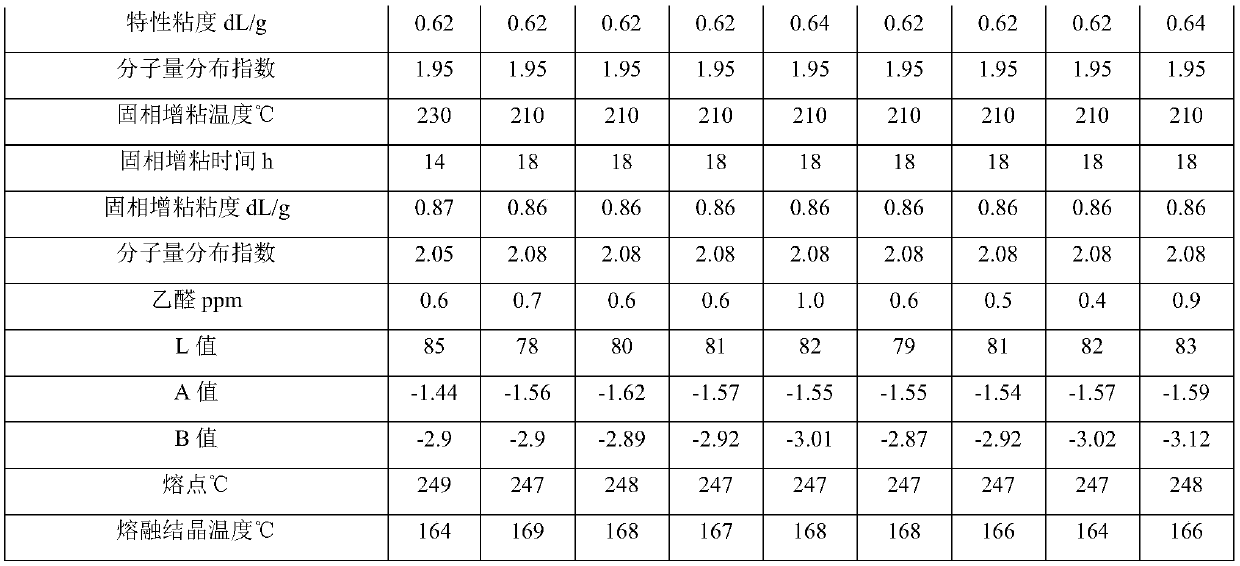

Embodiment 1

[0033] PET bottle-grade resin is made from terephthalic acid, isophthalic acid, ethylene glycol, colored waste PET polyester bottles, colorless waste PET polyester bottles, phosphoric acid, sodium acetate, and ethylene glycol antimony. Phthalic acid accounts for 69.8% of the total weight, isophthalic acid accounts for 1.8% of the total weight, colored waste PET polyester bottles account for 10% of the total weight, colorless waste PET polyester bottles account for 10% of the total weight, phosphoric acid accounts for 20ppm of the total weight, sodium acetate accounts for 50ppm of the total weight, and ethylene glycol antimony accounts for 170ppm of the total weight.

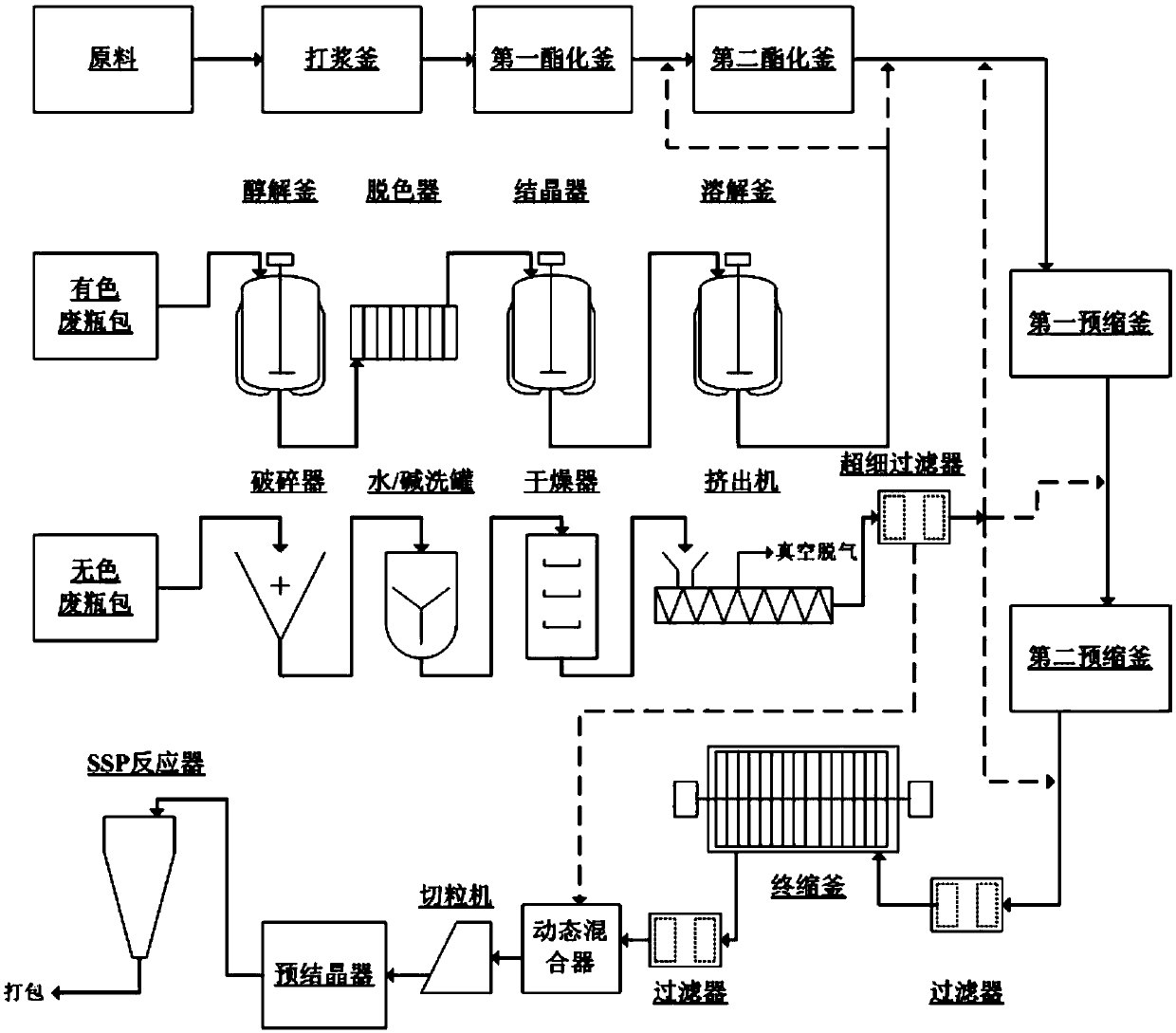

[0034] like figure 1 As shown, terephthalic acid, isophthalic acid, and ethylene glycol are beaten and mixed, and phosphoric acid and sodium acetate are added during the beating and mixing stage (to prevent the etherification of ethylene glycol in the conventional esterification process), and enter the first este...

Embodiment 2

[0038] PET bottle-grade resin is made from terephthalic acid, isophthalic acid, ethylene glycol, colored waste PET polyester bottles, colorless waste PET polyester bottles, phosphoric acid, sodium acetate, and ethylene glycol antimony. The amount of raw material, colored waste PET polyester bottle, and the treatment of colorless waste PET polyester bottle are the same as in Example 1, except that the filter melt of colorless waste PET polyester bottle is adjusted and added at the outlet of the first pre-shrinking kettle, and all the other process conditions are the same as those in Example 1. The same as in Example 1, after the polycondensation reaction, the tape was cast and pelletized, the intrinsic viscosity of the particles was controlled at 0.62dL / g, and the molecular weight distribution index was between 1.95. After drying and pre-crystallization, the particles enter the solid-phase viscosity-increasing reactor and react at a reaction temperature of 210°C for 18 hours to ...

Embodiment 3

[0041] PET bottle-grade resin is made from terephthalic acid, isophthalic acid, ethylene glycol, colored waste PET polyester bottles, colorless waste PET polyester bottles, phosphoric acid, sodium acetate, and ethylene glycol antimony. Raw material consumption, colored waste PET polyester bottle, the processing of colorless waste PET polyester bottle are the same as embodiment 1, except that the filter melt of colorless waste PET polyester bottle is adjusted and added at the outlet of the second pre-shrinking kettle, all the other process conditions are the same as The same as in Example 1, after the polycondensation reaction, the tape was cast and pelletized, the intrinsic viscosity of the particles was controlled at 0.62dL / g, and the molecular weight distribution index was 1.95. After drying and pre-crystallization, the particles enter the solid-phase thickening reactor and react at a reaction temperature of 210°C for 18 hours. The bottle-grade slices produced have an intrins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com