Underground brine collection and transport dedicated pump and its production method

A technology for underground brine and fresh water, applied in the direction of pumps, pump components, non-displacement pumps, etc., can solve problems such as equipment cannot operate normally, increase production costs, and unsatisfactory effects, and achieve good operating conditions, delaying crystallization speed, and running Life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

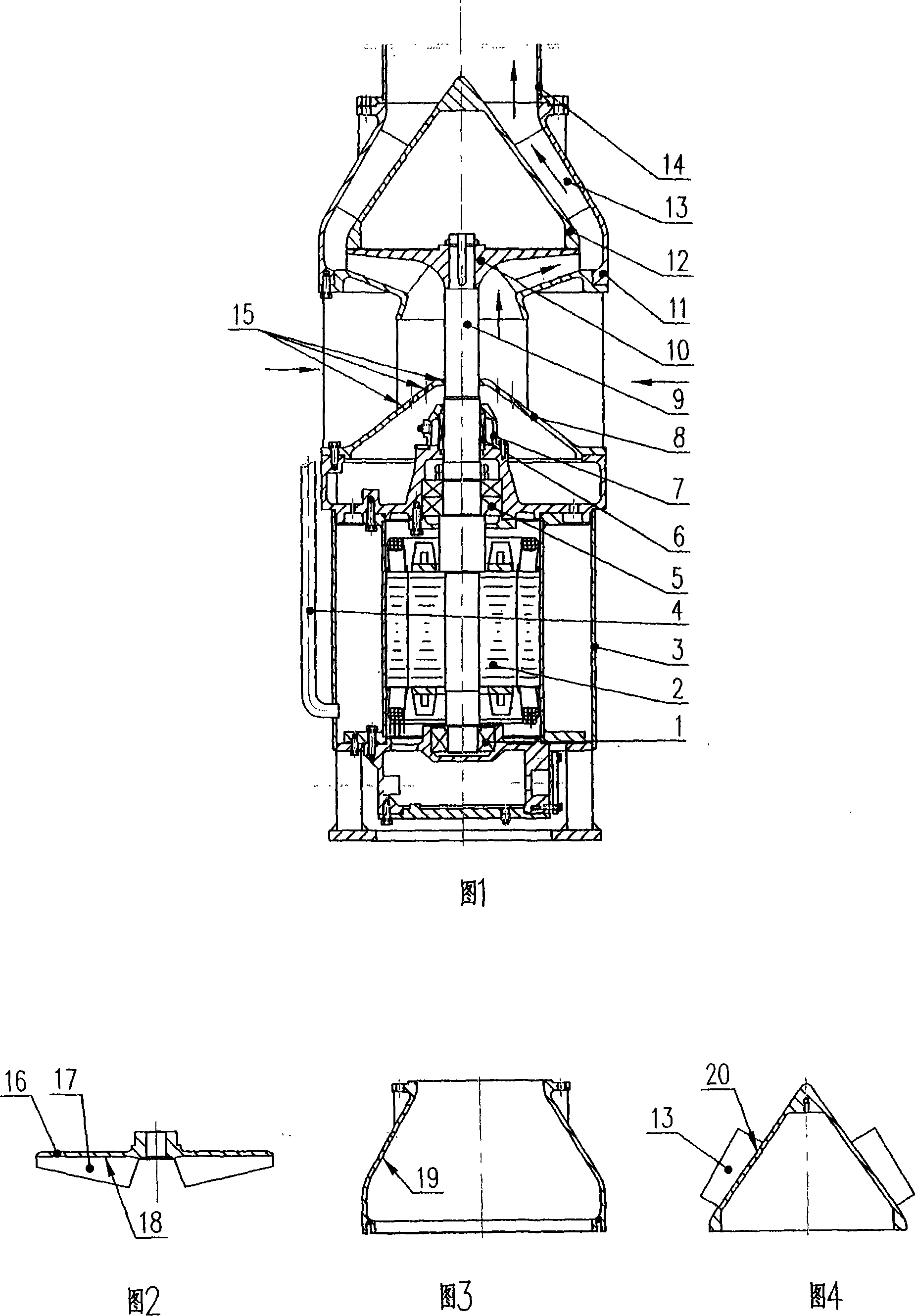

[0014] As shown in Figure 1, the present invention is a special pump for underground brine collection and transportation and its manufacturing method. The pump includes an impeller 10, a water inlet section 8 and a submersible motor 2 from top to bottom, and a pump shaft 9 vertically penetrates it. The feature is that the impeller 10 is set as a semi-open impeller structure, a guide core 12 is arranged above the impeller, guide vanes 13 are arranged on the conical surface of the guide core, and a guide shell 11 is arranged on the periphery of the guide core and guide vanes , the water jacket 3 is set on the periphery of the submersible motor, the fresh water input pipe 4 is set at the lower end of the water jacket, and the fresh water ejection hole 15 is set at the conical bottom of the water inlet section 8. In addition, at present, the underground brine collection pump widely adopts the combination of radial guide bearing and thrust disc at the place where the motor and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com