High-pressure grouting molding manufacturing process of toilet bowl, molding die of high-pressure grouting molding manufacturing process and ceramic toilet bowl

A technology of high-pressure grouting and forming molds, applied in the direction of die-casting molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of low output and efficiency, low product yield and quality, and high equipment costs, to improve output and efficiency, The effect of improving structural strength and quality and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

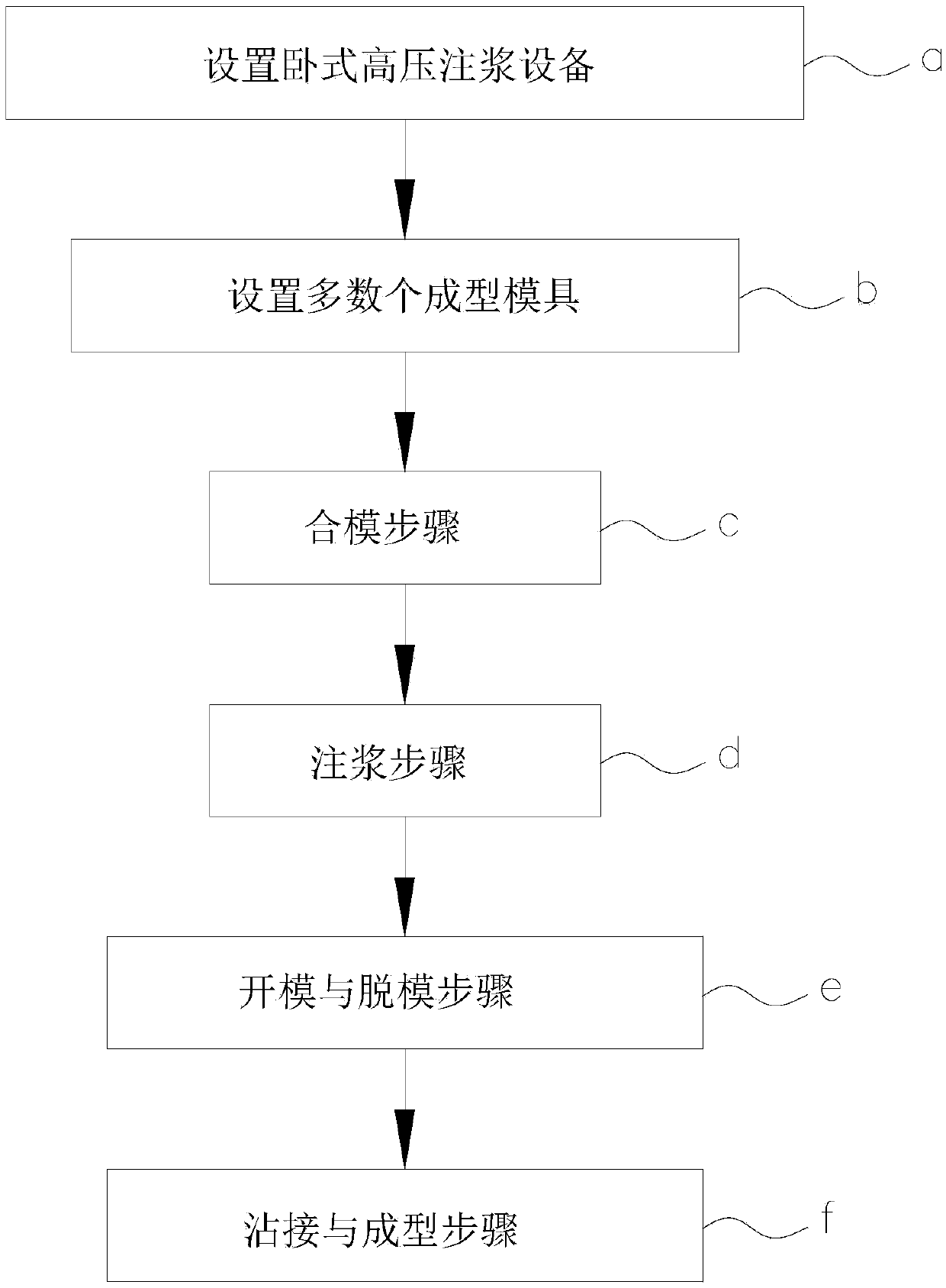

[0033] Such as figure 1 , 2 As shown, the present invention provides a preferred embodiment of the toilet seat high-pressure grouting molding process, which mainly includes the following method steps:

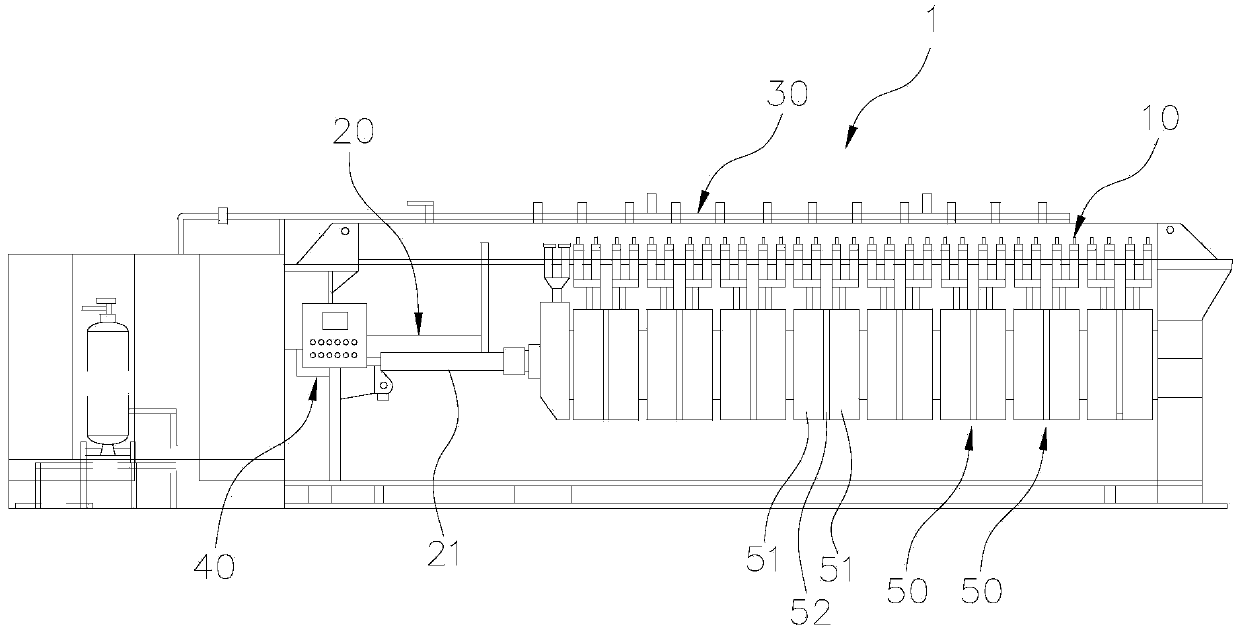

[0034] a. Horizontal high-pressure grouting equipment 1 is set, at least including bearing system 10, hydraulic system 20, mud grouting system 30 and electric control system 40; Side mold press cylinder 21. The carrying system 10 in this embodiment is a hanging carrying system, but it is not limited thereto, and may also be other forms of carrying system.

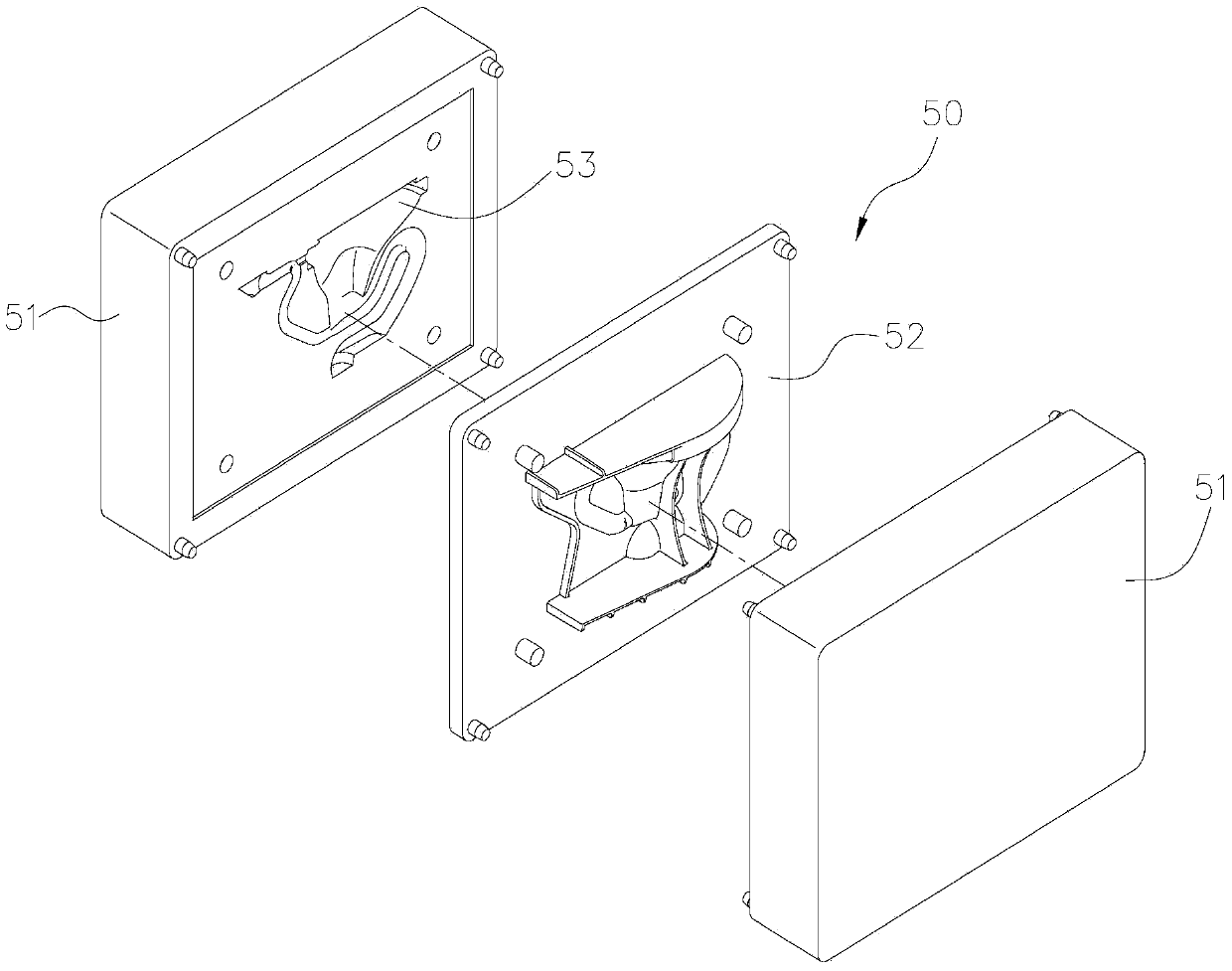

[0035] b. set a plurality of molding dies 50, such as image 3 As shown, each forming mold 50 includes two female molds 51 and a male mold 52 located between the two female molds 51 ;

[0036] c. mold clamping step, use the electric control system 40 to control the mold cylinder 21 of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com