Low voltage electromagnet for ceramic die

A ceramic mold and low-pressure technology, which is applied in the production of ceramic materials, die-casting molds, mold fixing devices, etc., can solve the problems of increasing the sealing of the main mold, troublesome operation, air leakage, etc., and achieve simple structure, easy operation, and safety performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

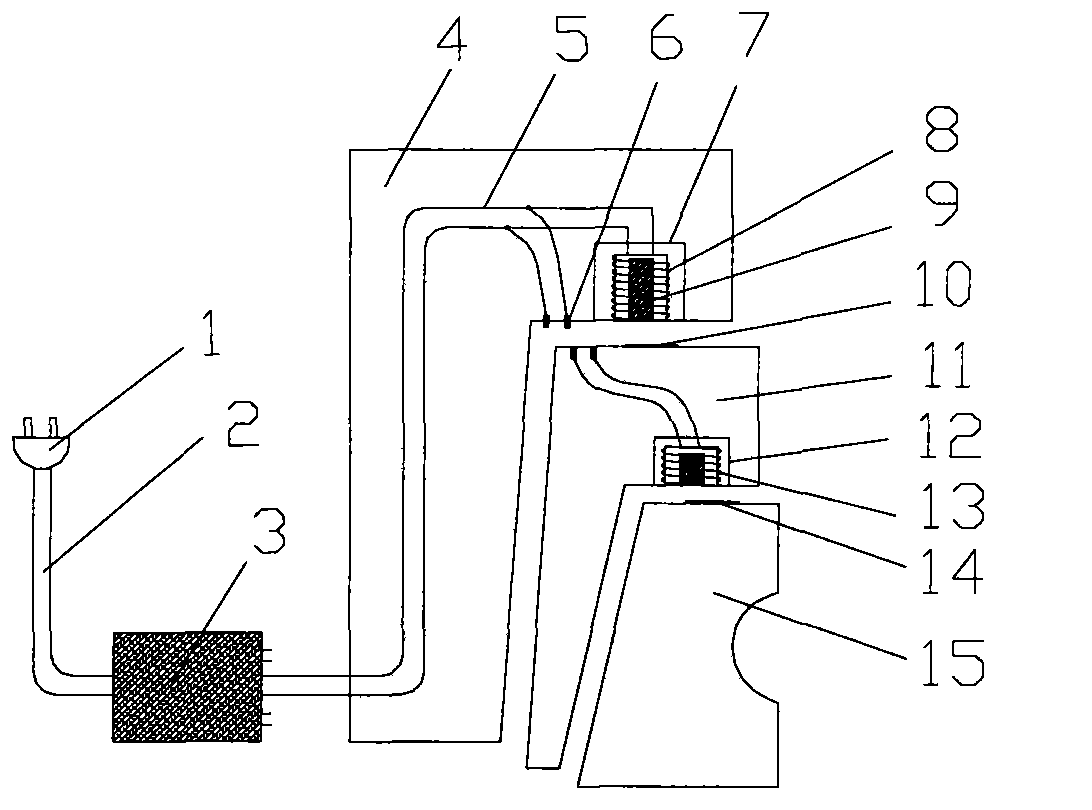

[0019] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0020] figure 1 The specific implementation of the low-voltage electromagnetic device for the ceramic mold of the present invention is shown. If we assume that the three modules of the main module 4, the middle module 11 and the small module 15 are to be quickly fixed and opened flexibly, we can connect the power plug 1 to the 220-volt mains, and after the rectifier 3 transforms and rectifies the , making the voltage on the low voltage line 5 lower than the safe voltage of 36 volts. Electromagnetic coil 8 and iron core 9 in the waterproof cover 7 produce magnetic force to the iron sheet 10 that structure is on the middle mold 11 and there is greater suction force, so just realized the fixing of main mold 4 and middle mold 11. Equally, after the safety voltage is sent to the B electromagnetic coil 13 that is positioned at the B waterproof cover 12 by the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com