Compression-casting production method of zinc alloy spectacles frame, spectacles arm or spectacles arm head

A production method and technology of spectacle feet, applied in the field of glasses and glasses, can solve problems such as not suitable for production in the glasses industry, cutting internal errors, complicated production processes, etc., and achieve the effects of low cost, diverse colors, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

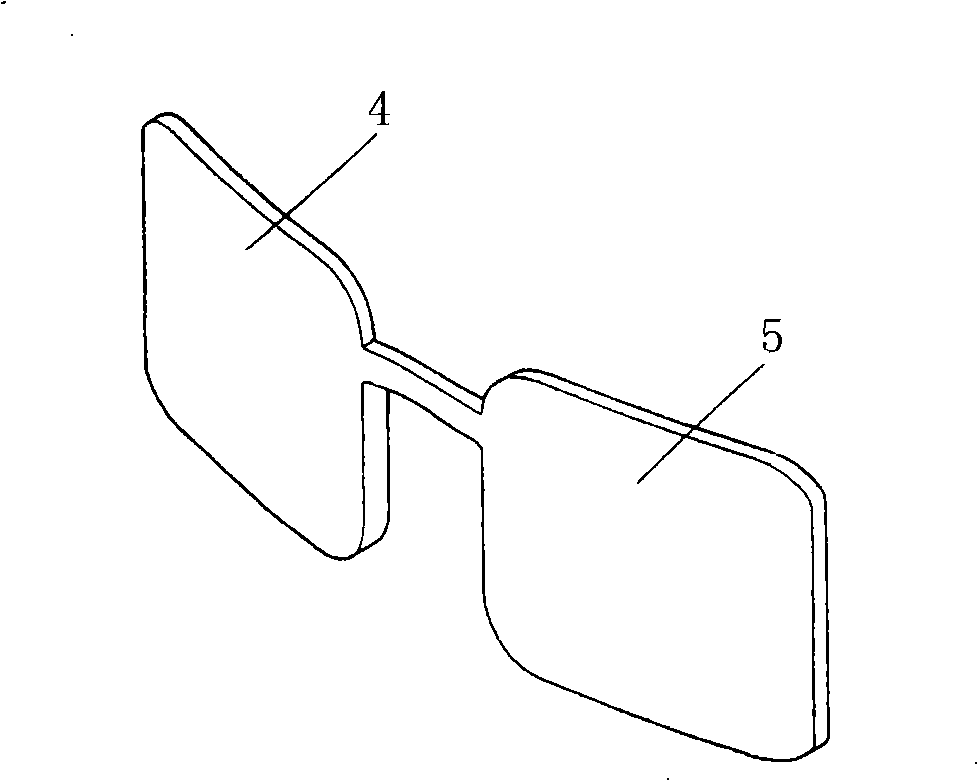

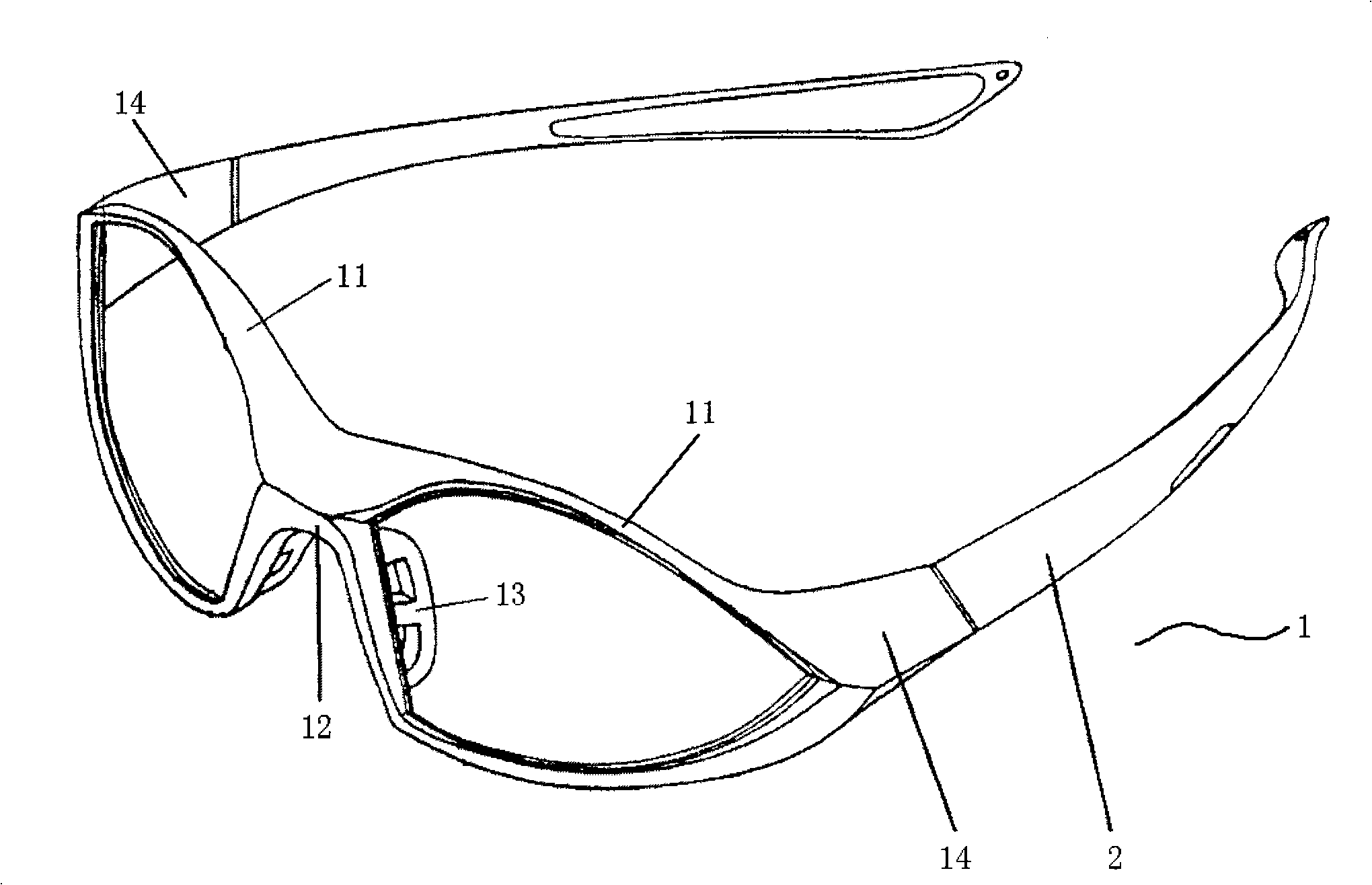

[0032] Example 1: Using the present invention to process temples 2, a 30-ton Lijin die-casting machine was selected, and the mold temperature was controlled at 160°C:

[0033] 1. Manufacture the corresponding die-casting mold according to the glasses leg 2 to be processed;

[0034] 2. Hot-melt the die-cast zinc alloy and inject it into the die-casting mold through a die-casting machine for preliminary processing;

[0035] 3. After the zinc alloy melt is cooled, it is demoulded, and then machined, polished and electroplated.

Embodiment 2

[0036] Example 2: The present invention is used to process the eyeglasses 3, a 50-ton die-casting machine of Zhengao brand is selected, and the mold temperature is controlled at 185°C:

[0037] 1. Manufacture the corresponding die-casting mold according to the glasses foot 3 to be processed;

[0038] 2. Hot-melt the die-cast zinc alloy and inject it into the die-casting mold through a die-casting machine for preliminary processing;

[0039] 3. After the zinc alloy melt is cooled, it is demoulded, and then machined, polished and electroplated.

Embodiment 3

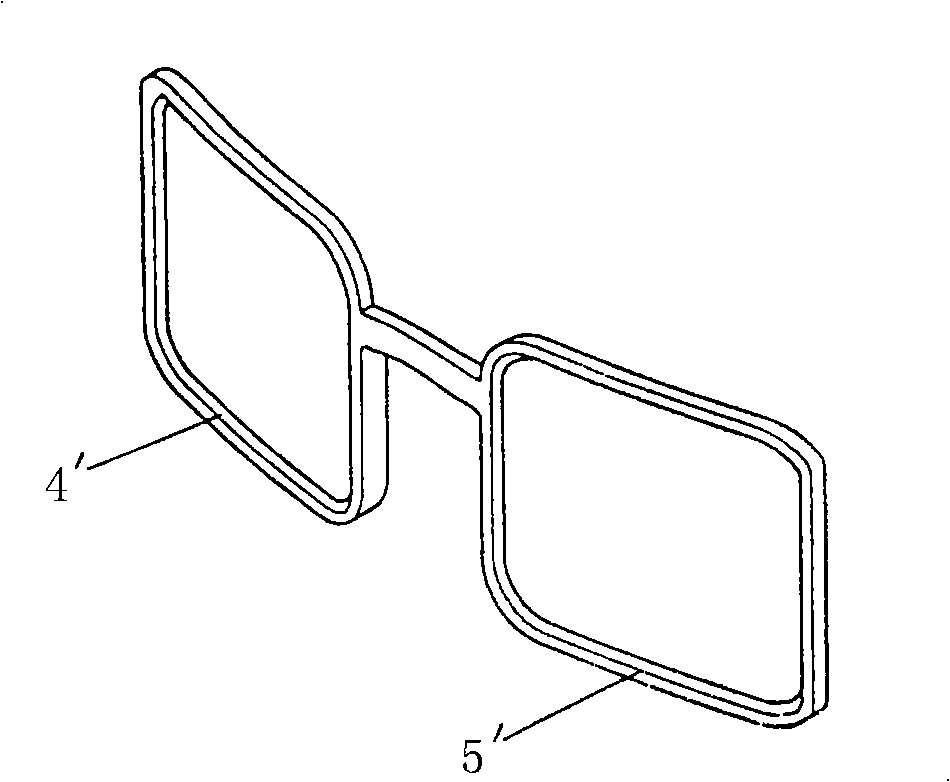

[0040] Example 3: Using the present invention to process half-rim glasses frame 1', a 130-ton Lijin die-casting machine was selected, and the mold temperature was controlled at 200°C:

[0041] 1. Manufacture the corresponding die-casting mold according to the half-rim glasses frame 1'to be processed;

[0042] 2. Hot-melt the die-cast zinc alloy and inject it into the die-casting mold through a die-casting machine for preliminary processing;

[0043] 3. After the zinc alloy melt is cooled, it is demoulded, and then machined, polished and electroplated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com