Method for supplying liquid to magnesium-alloy press caster and liquid supplier

A technology for die-casting machines and magnesium alloys, which is applied in the field of liquid supply and liquid supply devices for die-casting machines for magnesium alloy die-casting. The effect of reducing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

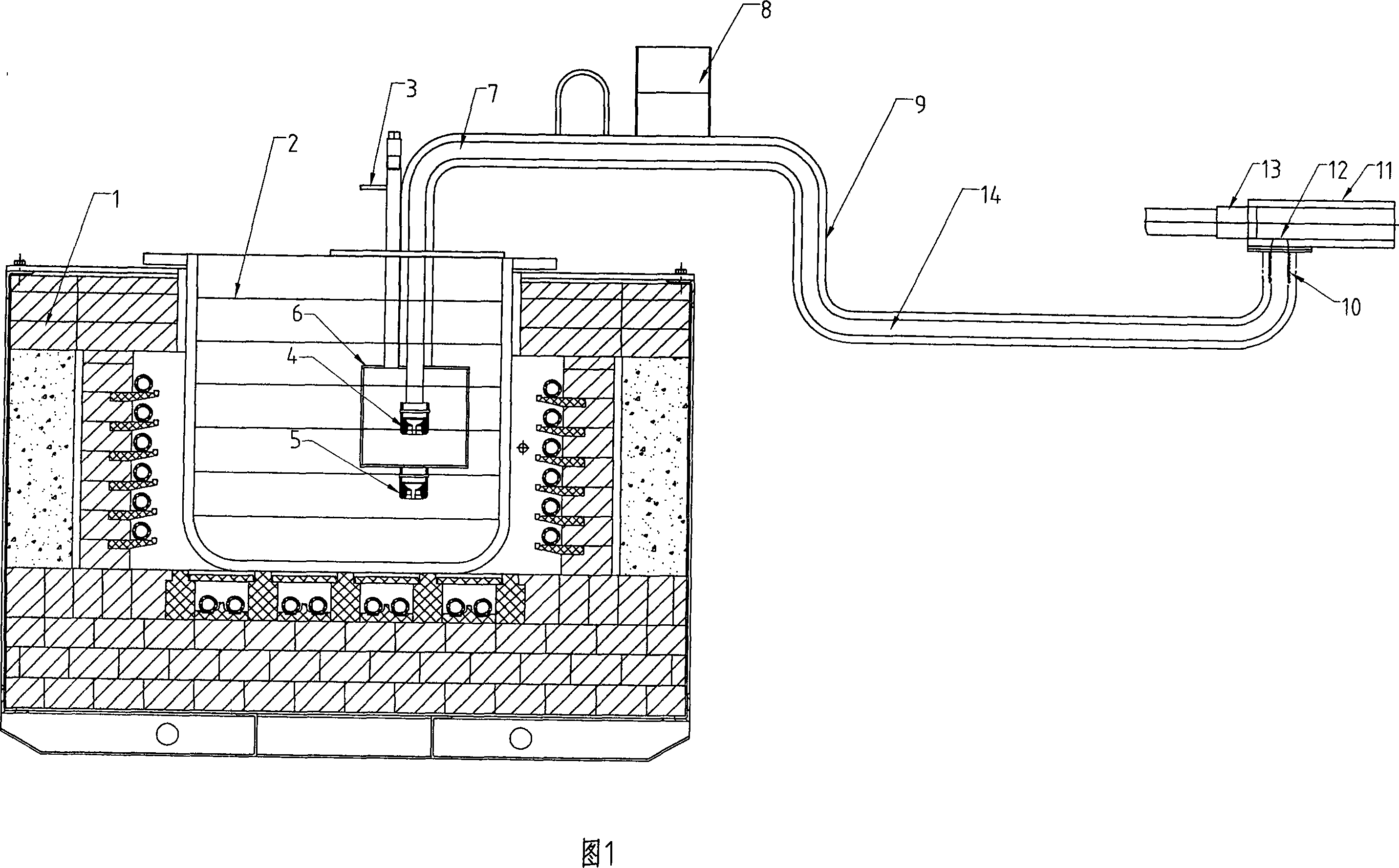

[0010] In Fig. 1, the magnesium alloy melting and holding furnace 1 ensures that the magnesium alloy liquid meets the temperature requirements of the die-casting process, and the crucible therein is used to melt the magnesium alloy. The quantitative pump housing 6 of the quantitative pump 7 is below the magnesium alloy liquid level 2 in the crucible. There is a bottom valve 4 in the quantitative pump housing 6 that communicates with the inlet of the infusion tube 14. There is a quantitative bottom valve 5 below the quantitative pump housing 6. The top of the quantitative pump casing 6 communicates with the inert gas inlet and exhaust pipe 3 protruding from the liquid surface. The bottom valve 4 and the quantitative bottom valve 5 are check valves. The infusion tube 14 is basically wrapped by the electric heating tube 9, and the electric heating wire 10 connected with the resistance wire heating device 8 is arranged in the electric heating tube 9. The infusion tube 14 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com