High temperature aluminium alloy

a technology of aluminium alloy and high temperature, applied in the field of aluminum alloy, can solve the problems of increasing hot shortness and negative effect on castability, and achieve the effect of satisfying mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

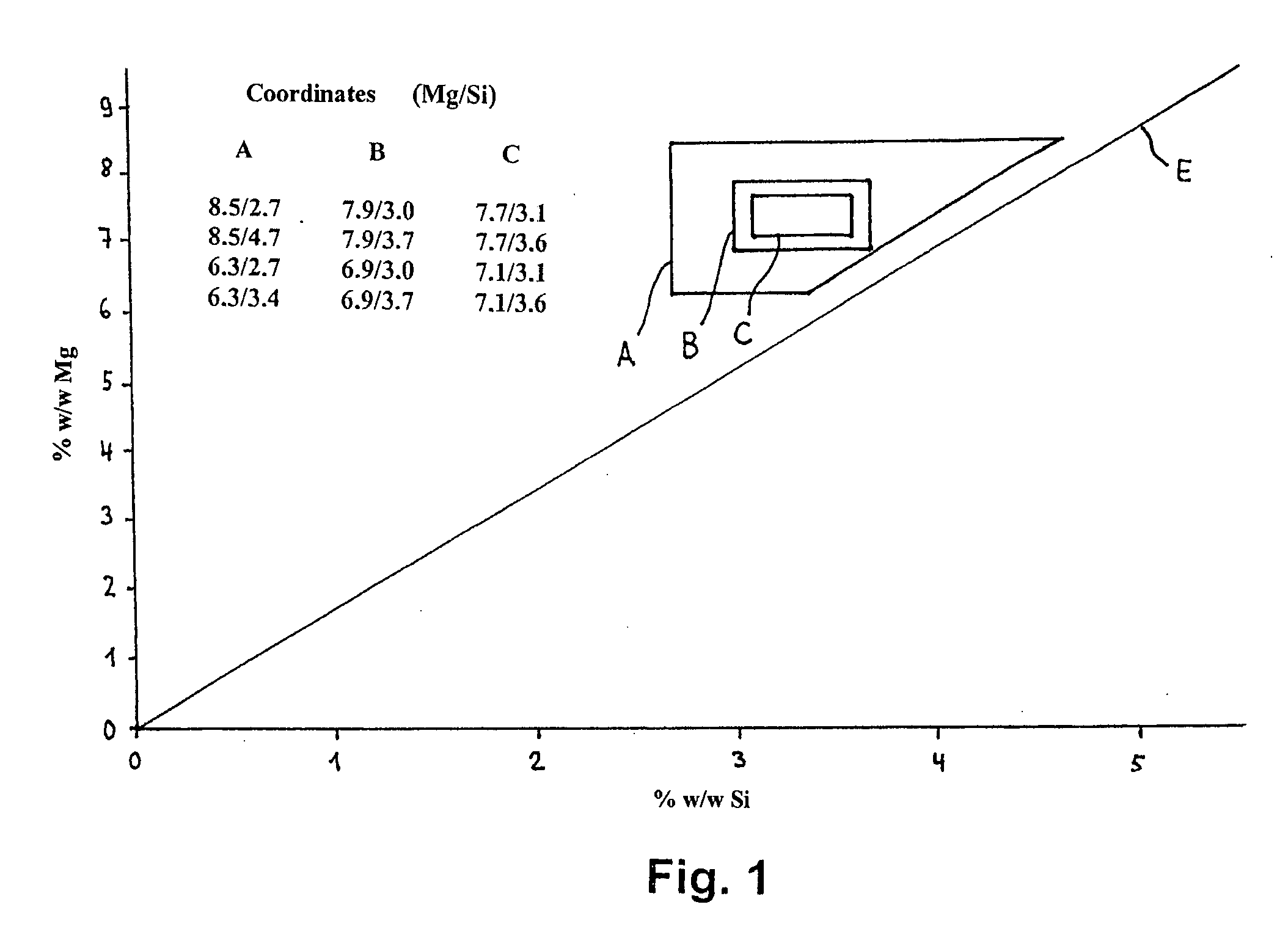

[0028]The polygon A shown in FIG. 1 defines the content range for the alloying elements Mg and Si, the polygons B and C refer to preferred ranges. The straight line E corresponds to the composition of the quasi-binary eutectic Al—Mg2Si. The alloy compositions according to the invention thus lie on the side with an excess of magnesium.

[0029]The alloy according to the invention was cast into pressure die cast plates with different wall thicknesses. Tensile strength test specimens were manufactured from the pressure die cast plates. The mechanical properties proof strength (Rp0.2), tensile strength (Rm) and elongation at break (A) were determined on the tensile strength test specimens in the conditions[0030]F As cast[0031]Water / F As cast, quenched in water after demoulding[0032]F>24 h As cast, >24 h storage at room temperature[0033]Water / F>24 As cast, quenched in water after demoulding, >24 h storage at room temperature

and after various single-stage heat treatment processes at temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| creep strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com