Heat resistant aluminium alloy

An aluminum alloy, heat resistance technology, applied in the field of AlMgSi type aluminum alloy, can solve the problems of increasing heat cracking tendency, castability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

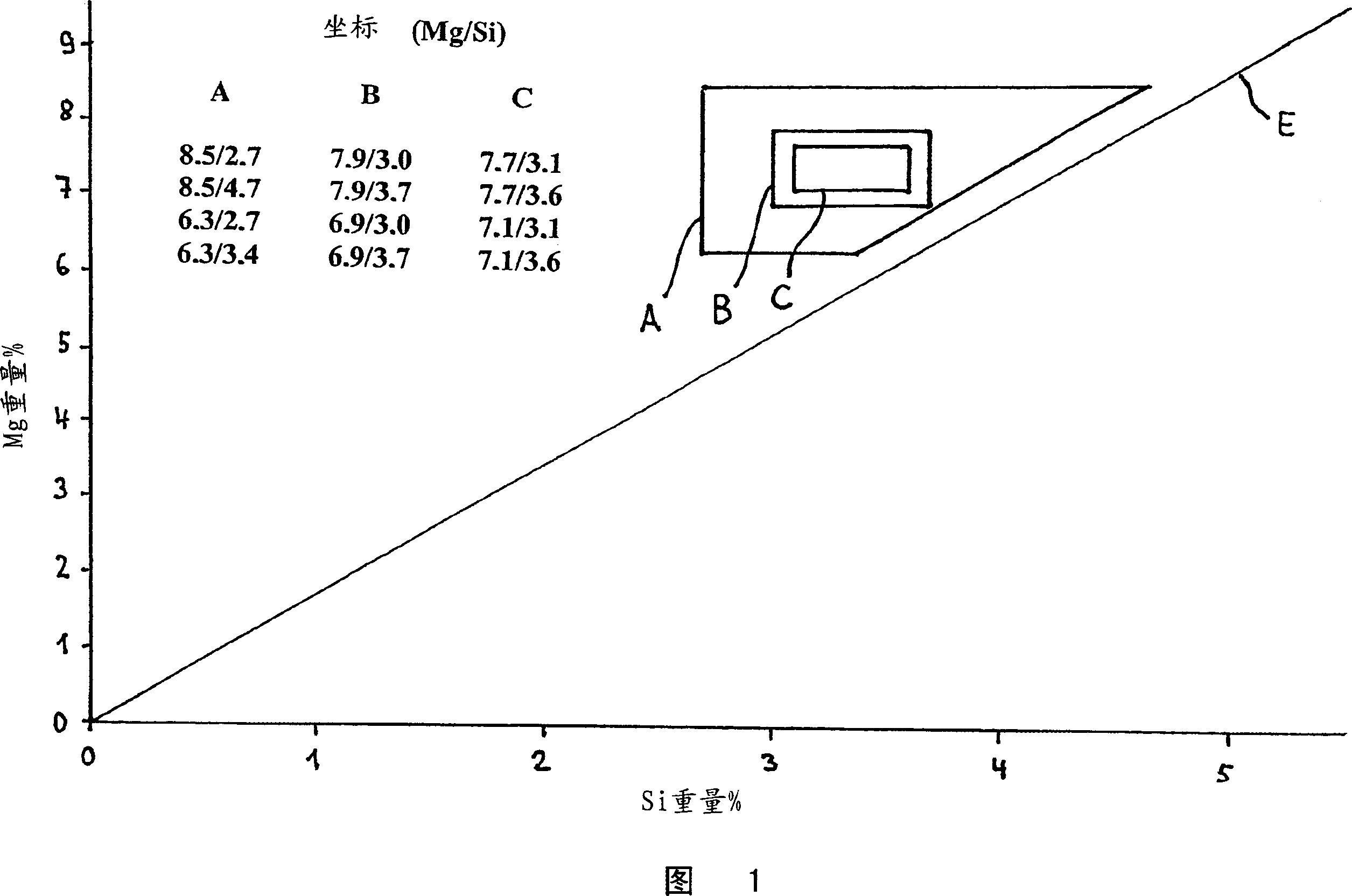

[0051] Polygon A shown in FIG. 1 defines the content ranges of alloying elements Mg and Si, and polygons B and C refer to preferred ranges. Line E corresponds to the quasi-binary eutectic Al-Mg 2 The composition of Si. Therefore, the alloy composition of the present invention is on the magnesium excess side.

[0052] The alloys of the invention were cast into die-cast sheets with different wall thicknesses. Tensile samples were made from these die-cast sheets. The mechanical properties, i.e. limit of elongation (Rp0.2), tensile strength (Rm) and elongation at break (A), were determined on tensile samples in the following states:

[0053] F casting state

[0054] Water / F cast state, quenched in water after demoulding

[0055] F>24h cast state, storage at room temperature>24h

[0056]Water / F > 24h As cast, quenched in water after demoulding, and stored at room temperature > 24h and after different one-step heat treatments in the temperature range 250°C to 380°C and in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com