High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

A technology for casting aluminum alloys and cast aluminum alloys, which is applied in the field of industrial aluminum alloys and manufacturing, can solve the problems of high standard electrode potential of Cu-rich phase, poor welding and brazing performance, and high Cu content, so as to improve mechanical properties and Corrosion resistance, good corrosion resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

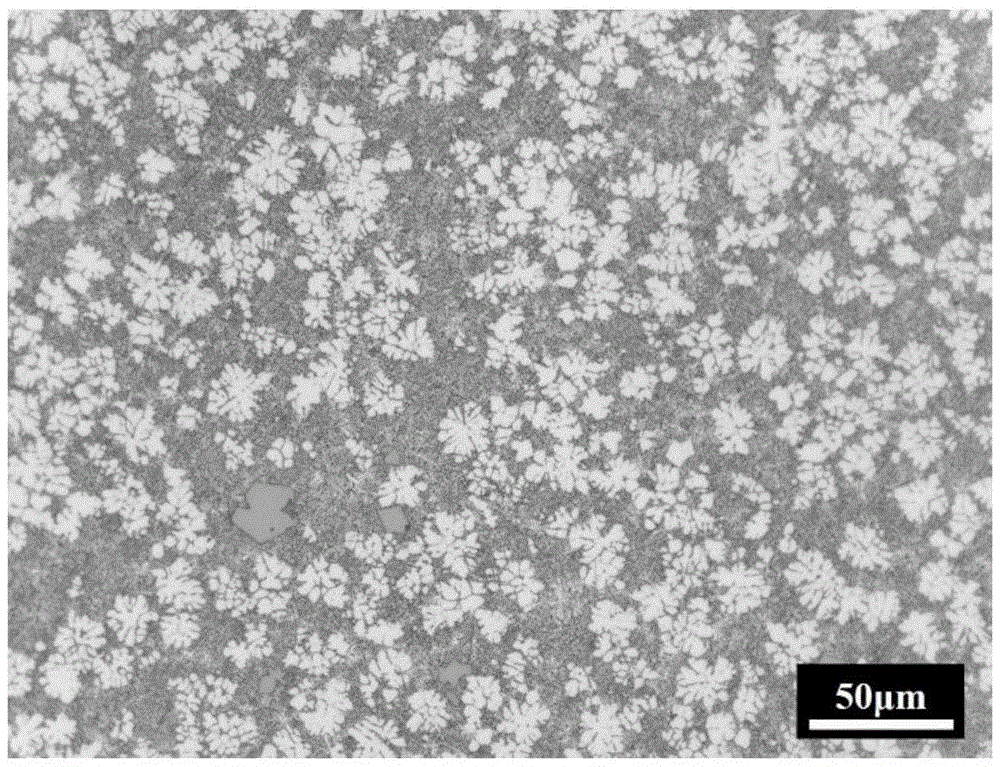

Embodiment 1

[0033] The weight percentage of a high-strength and high-corrosion-resistant cast aluminum alloy is: according to the theoretical ratio, Si12%, Mg0.4%, Mn0.5%, Zn0.5%, Sr0.04%, Cu0.25%, Ti0. 3%, Zr0.3%, V0.3%, Fe0.6%, the balance is Al and inevitable impurities.

[0034] The preparation method is (1) combining industrial pure aluminum (Al: 99.7 wt %), industrial pure magnesium (Mg: 99.95 wt %) and industrial pure zinc (Zn: 99.9 wt %), and intermediate alloys AlSi23, AlMn10, AlZr4, AlTi5B1, AlV5, AlFe20, AlCu50 and AlSr10 were polished with 320-grit sandpaper to remove the oxide layer, respectively, and placed in a blast drying oven (200 °C) for drying and preheating; (2) Use a stainless steel crucible for alloy casting, before using the crucible , slag removal tools, bell jars and other surfaces are cleaned and derusted and coated with paint. The paint is mixed with 25% talcum powder and 5% water glass and added with appropriate amount of water, and then placed in a 200 ℃ oven...

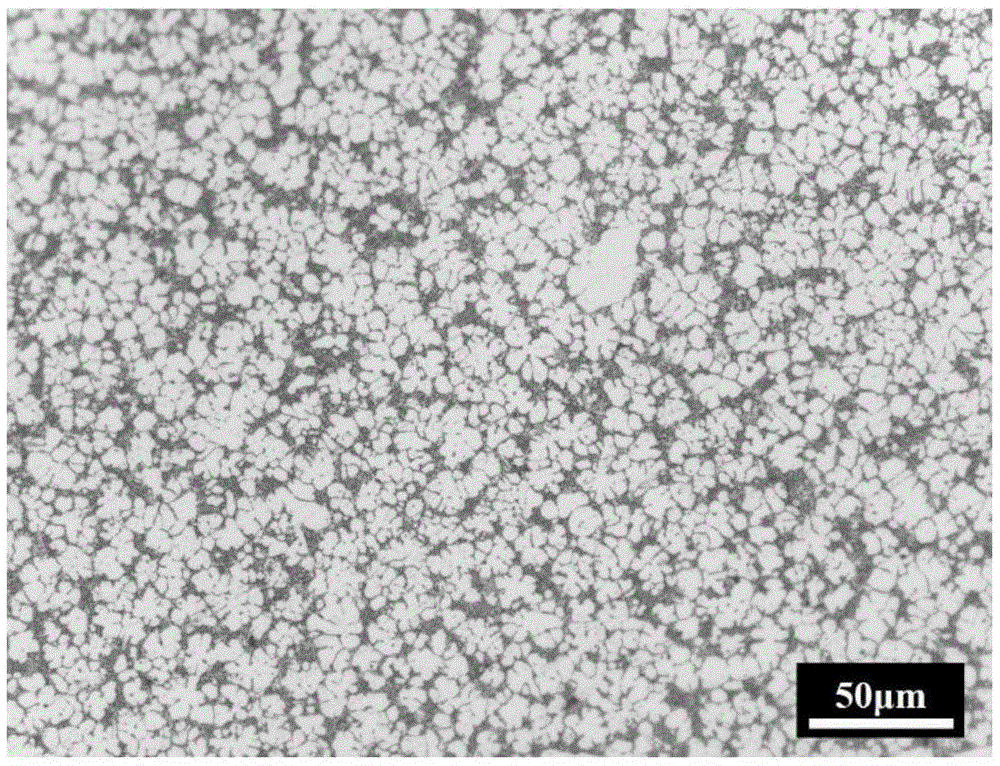

Embodiment 2

[0039] The weight percentage of a high-strength and high-corrosion-resistant cast aluminum alloy is: according to the theoretical ratio, Si7%, Mg0.2%, Mn0.2%, Zn0%, Sr0.02%, Cu0%, Ti0.01%, Fe0 .4%, the balance being Al and inevitable impurities.

[0040] The preparation method is as follows: (1) industrially pure aluminum (Al: 99.7wt%) and industrially pure magnesium (Mg:99.95wt%), and intermediate alloys AlSi23, AlMn10, AlFe20, AlTi5B1 and AlSr10 are respectively polished with 320-mesh sandpaper to remove oxidation. (2) Use a stainless steel crucible for alloy casting, clean the surface of the crucible, slag removal tool, bell jar, etc. before use, remove rust and coat with paint. The coating is made of 25% talc powder and 5% water glass and then added with an appropriate amount of water. It can be used after baking in a 200 ℃ oven overnight to remove the water. The temperature gradient of the resistance heating furnace is raised to 710 ℃. After pure aluminum with about 10% ...

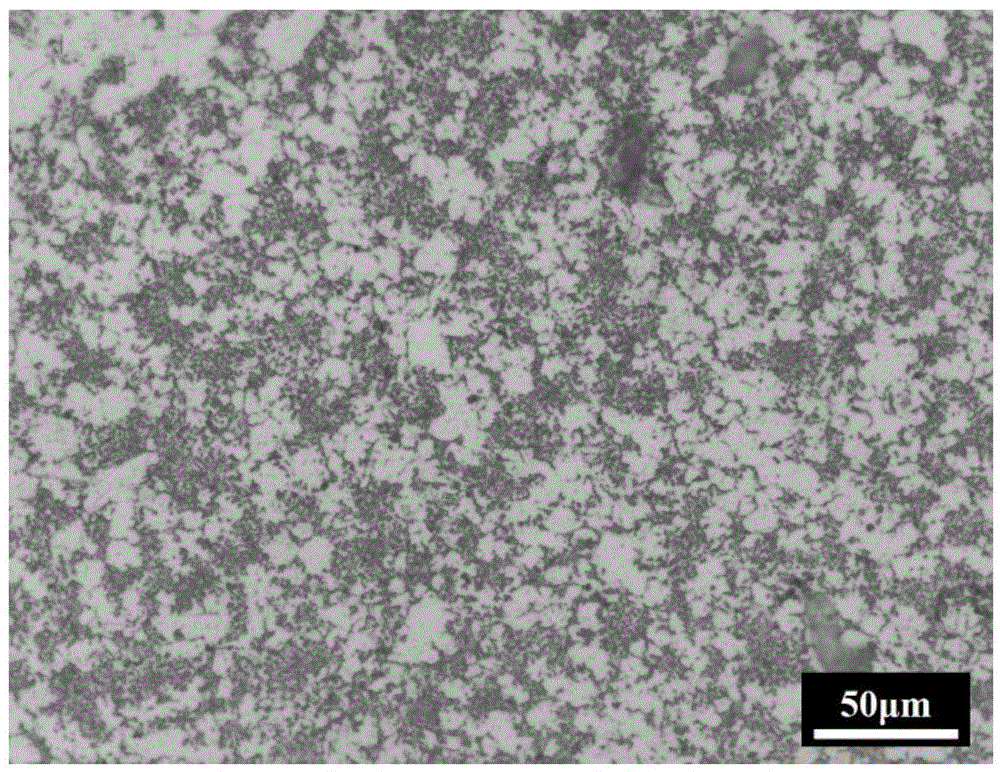

Embodiment 3

[0045] The weight percentage of a high-strength, high-corrosion-resistant cast aluminum alloy and a preparation method thereof is: according to the theoretical ratio, Si15%, Mg0.6%, Mn1%, Zn1%, Sr0.1%, Cu0.5%, Ti0. 5%, Zr0.5%, V0.5%, Fe1%, the balance is Al and inevitable impurities.

[0046] The preparation method is (1) combining industrial pure aluminum (Al: 99.7 wt %), industrial pure magnesium (Mg: 99.95 wt %) and industrial pure zinc (Zn: 99.9 wt %), and intermediate alloys AlSi23, AlMn10, AlZr4, AlTi5B1, AlV5, AlFe20, AlCu50 and AlSr10 were polished with 320-grit sandpaper to remove the oxide layer, respectively, and placed in a blast drying oven (200 °C) for drying and preheating; (2) Use a stainless steel crucible for alloy casting, before using the crucible , slag removal tools, bell jars and other surfaces are cleaned and derusted and coated with paint. The paint is mixed with 25% talcum powder and 5% water glass and added with appropriate amount of water, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com