PLC control system and method of servo energy-saving control system of ceramic press

An energy-saving control system and control system technology, applied in the direction of fluid pressure actuation system components, servo motors, servo motor components, etc., can solve the problems of oil cylinders not working, the system cannot supply oil on demand, and energy loss, etc., and achieve reduction The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0051] In order to achieve the first purpose of the present invention, the technical scheme adopted in the present invention is as follows:

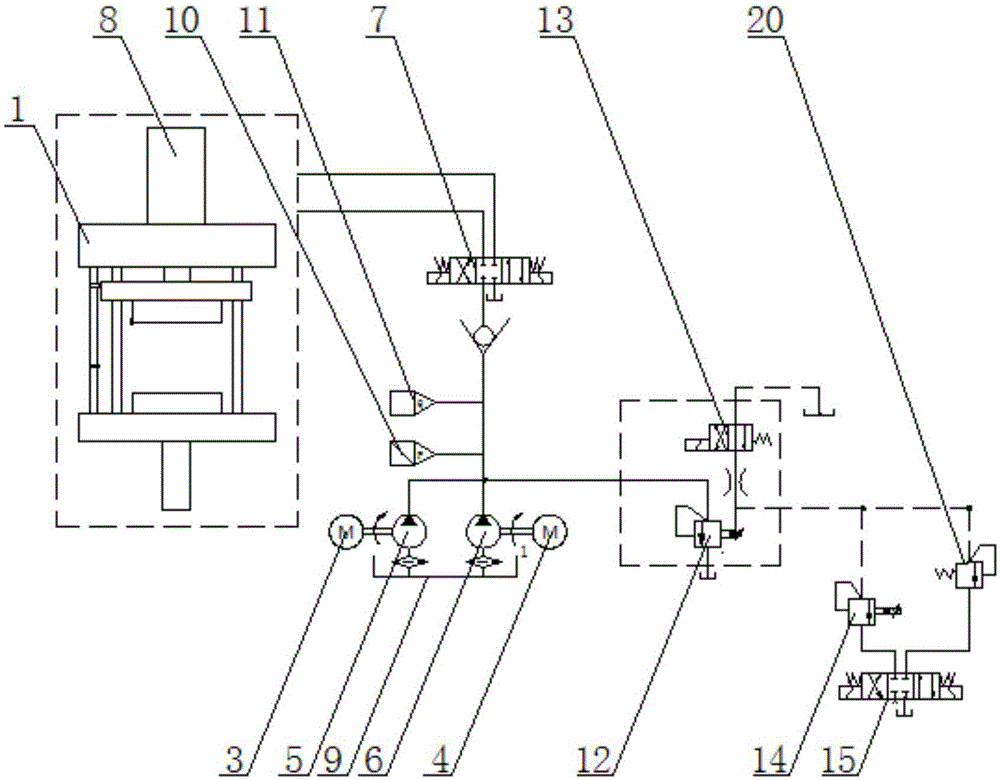

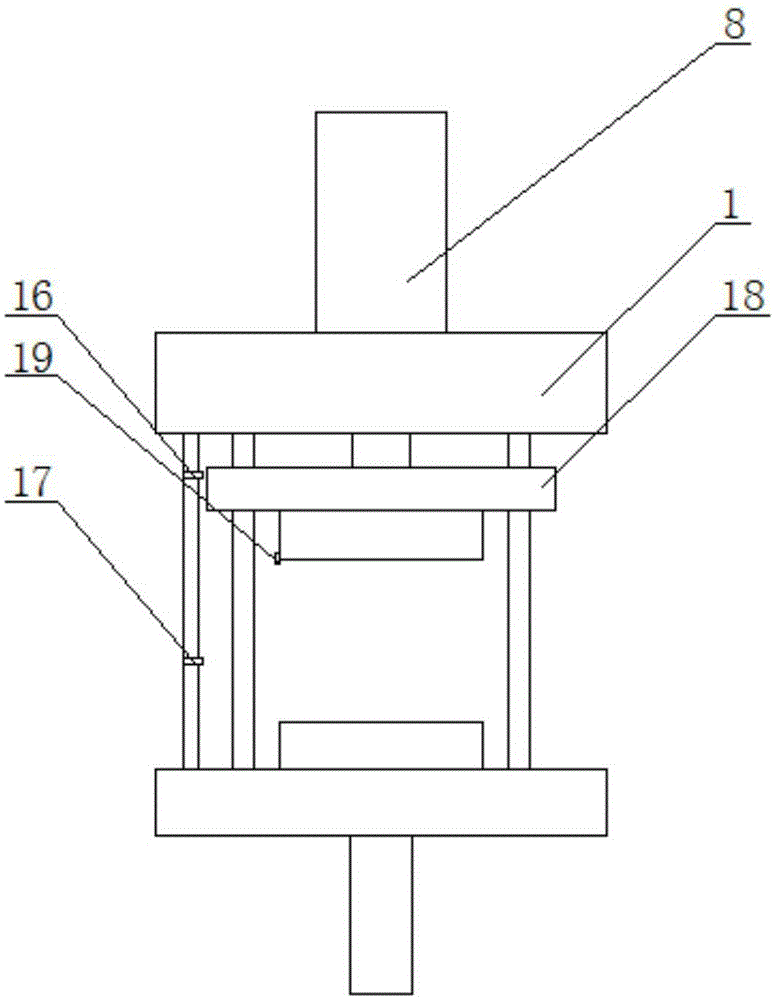

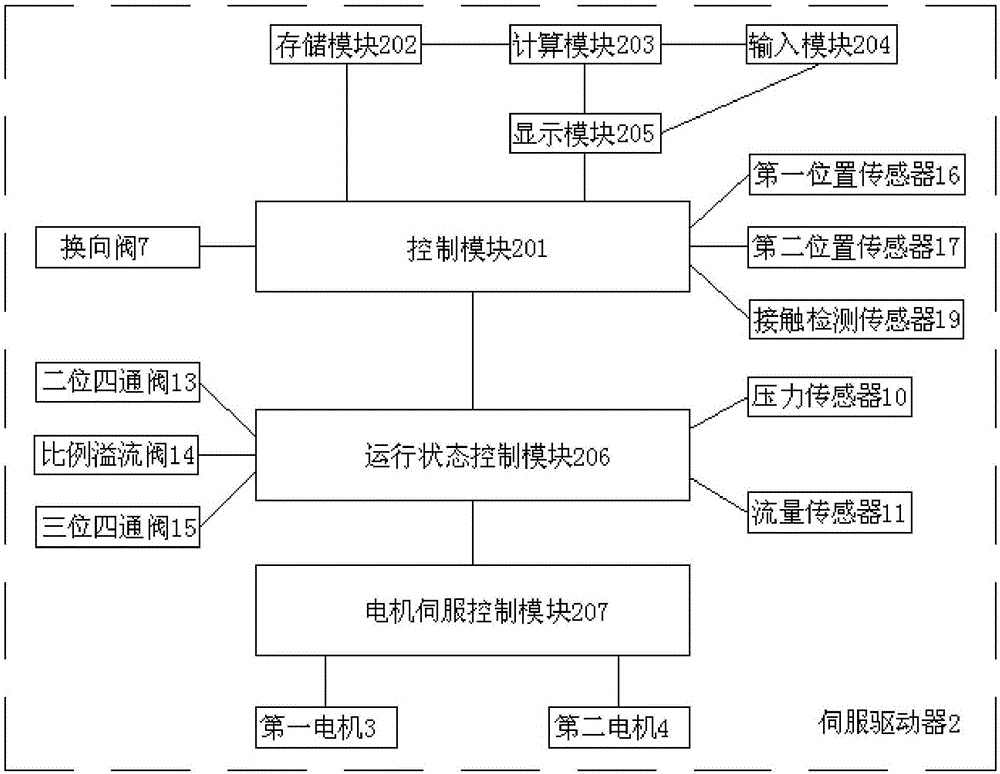

[0052] refer to figure 1 , figure 2 As shown, the PLC control system of a ceramic press servo energy-saving control system provided by the present invention includes a die-casting machine 1, a servo driver 2, a first motor 3, a first oil pump 5, a reversing valve 7, an oil cylinder 8, and an oil tank 9 , a pressure sensor 10, a flow sensor 11, the oil outlet of the first oil pump 5 is also communicated with the oil tank 9 through a pilot relief valve 12, and the pressure regulating end of the pilot relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com