Method and drive system for the control/regulation of linear pressure/cast movement

a technology of linear pressing/casting movement and drive system, which is applied in the direction of positive displacement liquid engine, mechanical apparatus, pumps, etc., can solve the problems of relative advantageous structural complexity, and achieve the effects of small increase complexity, high loss, and increased pressing/casting movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

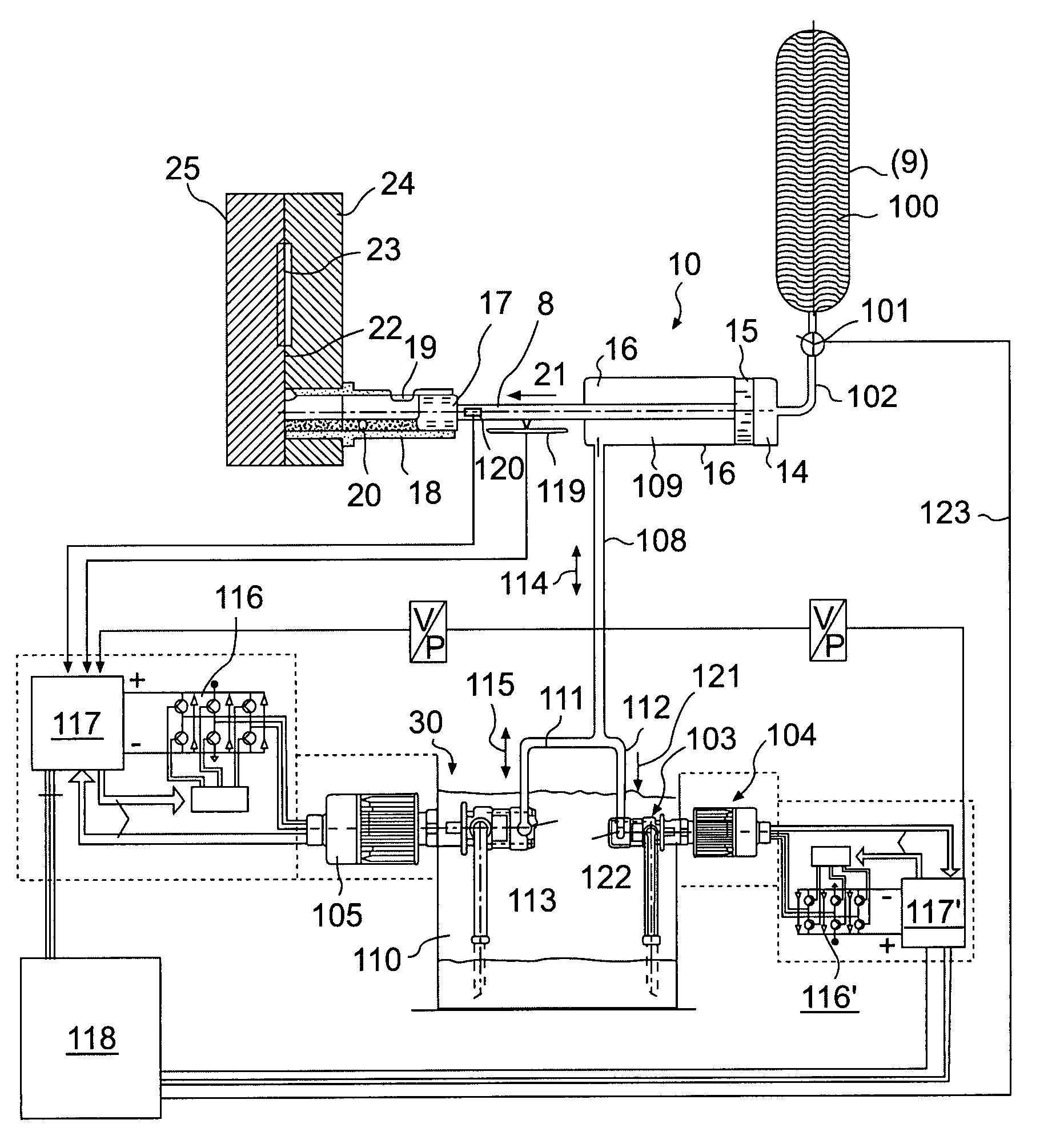

[0027] It can be seen in FIGS. 7 and 8 that the structural embodiment of the casting equipment is unchanged in comparison with the known designs. However, the elements for control of the oil flow on the piston rod side are designed according to a completely novel concept. A liquid medium, i.e., a hydraulic oil, is proposed as the medium on the piston rod side, circulating through a connecting line 108 / 111 between chamber 109 on the piston rod side of the casting driving cylinder 16 and a preferably closed tank 110. The oil flow passes through line 108 and is conveyed directly through a pump 30 and line 113. As indicated by the two arrows 114 and 15, the oil flow may go in one direction or the other as needed. Pump 30 is driven by a servo motor 105 and has the properties described in European Patent 782 671 and WO97 / 05387, for example. servo motors are characterized in particular by an electronic power unit 116 by which all the important parameters can be controlled virtually simulta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydraulic pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com