Bearing holder near net shape casting method

A bearing cage and near-net-shape technology, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of low metal utilization rate, achieve the effects of improving production efficiency, reducing production costs, and good crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

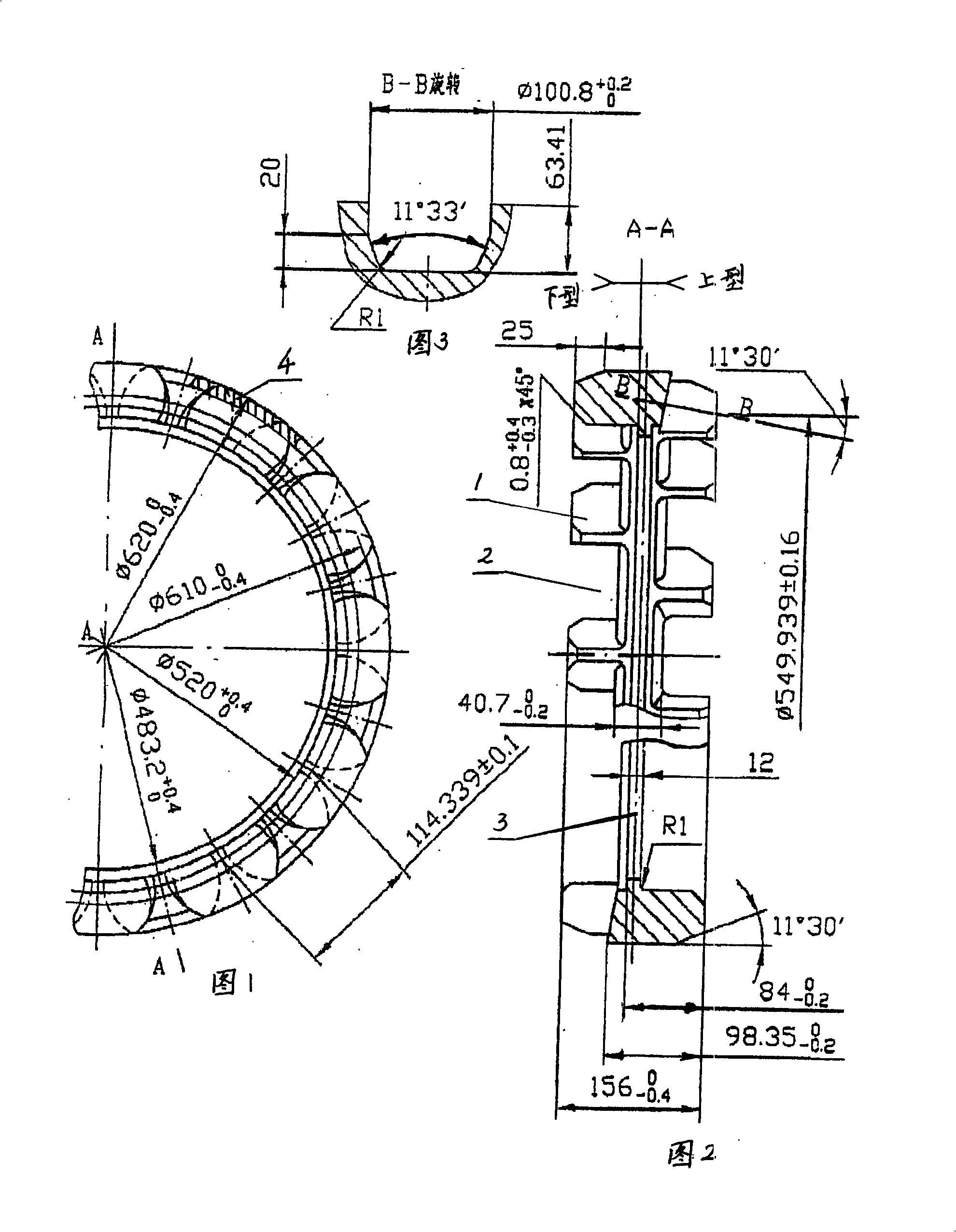

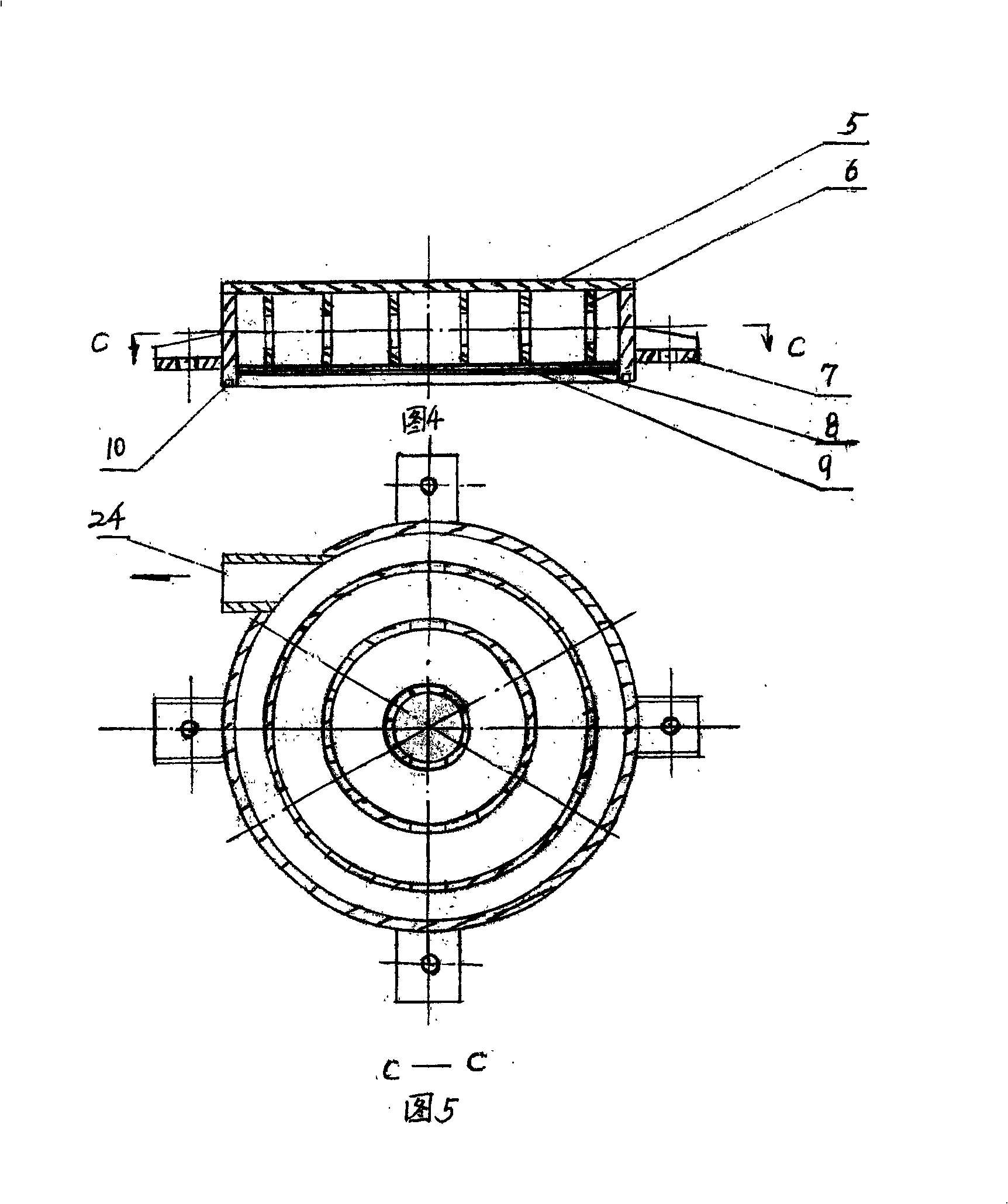

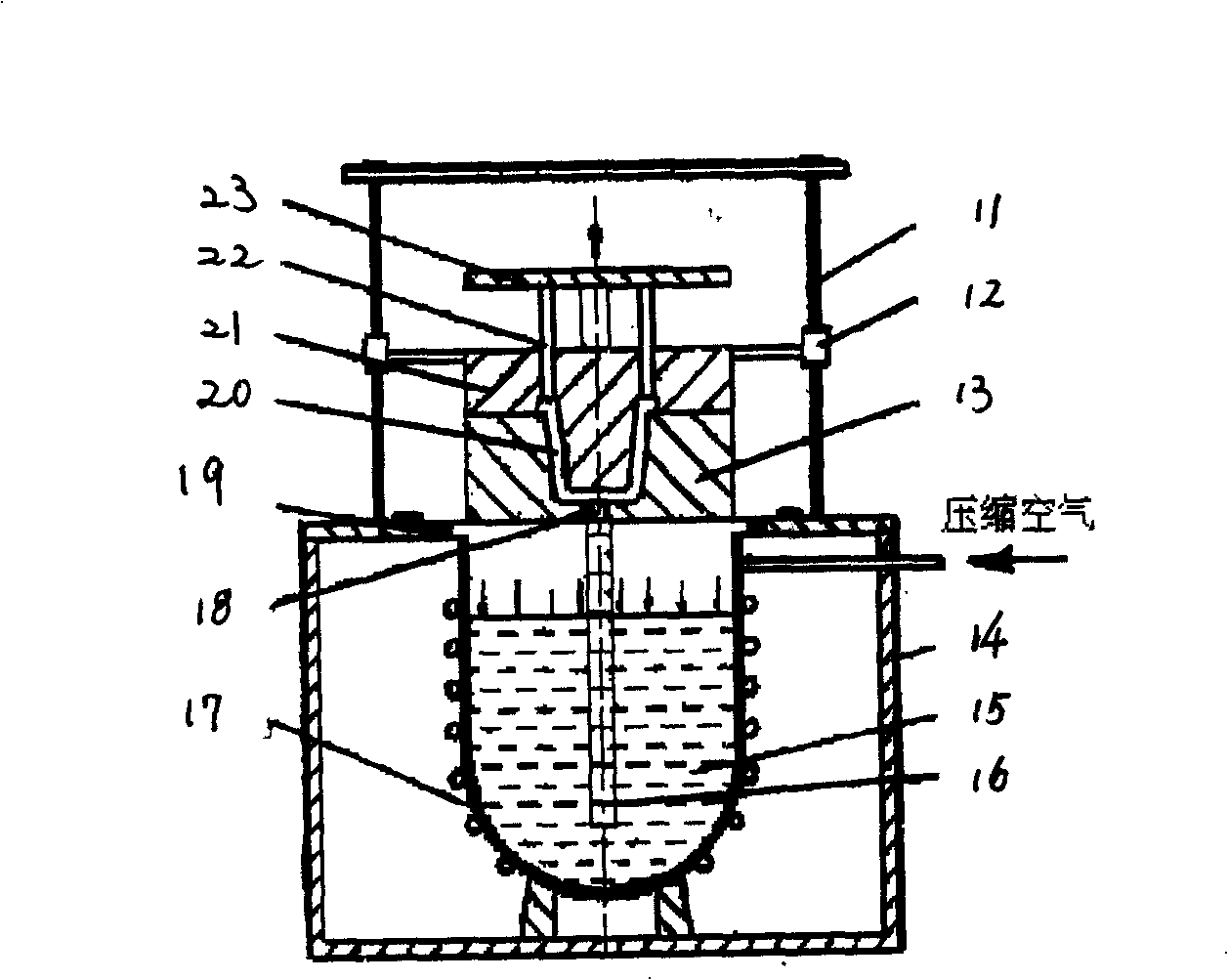

[0029] The near-net-shape casting method of the bearing cage of the present invention can approximately cast the support arm of the cage and the prototype of the pocket hole, leaving only a small amount of machining allowance required for the lathe to correct the shape and the pocket hole processing between the support arms. Clean shape casting. To optimize the casting forming method, adopt simple and practical casting technology (rather than investment casting, die casting, squeeze casting and other complex processes) to make the casting close to the final shape and dimensional accuracy of the part, improve production efficiency, reduce production cost, and realize Large-scale industrial production. Its main technical points are:

[0030] 1) As shown in Figure 1-3, the shape of the cage is made to be close to the shape and dimensional accuracy of the final part, and the shape is divided horizontally. Install (multi-piece arrangement) quick-change molds to ensure the strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com