Two-plate high-speed pressure die-casting machine

A die-casting machine, two-plate technology, applied in the field of two-plate high-speed die-casting machines, can solve the problems of uneven force on the large lever, many wearing parts, and high maintenance costs, so as to extend the operating life and the accuracy, length and large size of the machine. The effect of shortening the length of the bar and simplifying the clamping mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

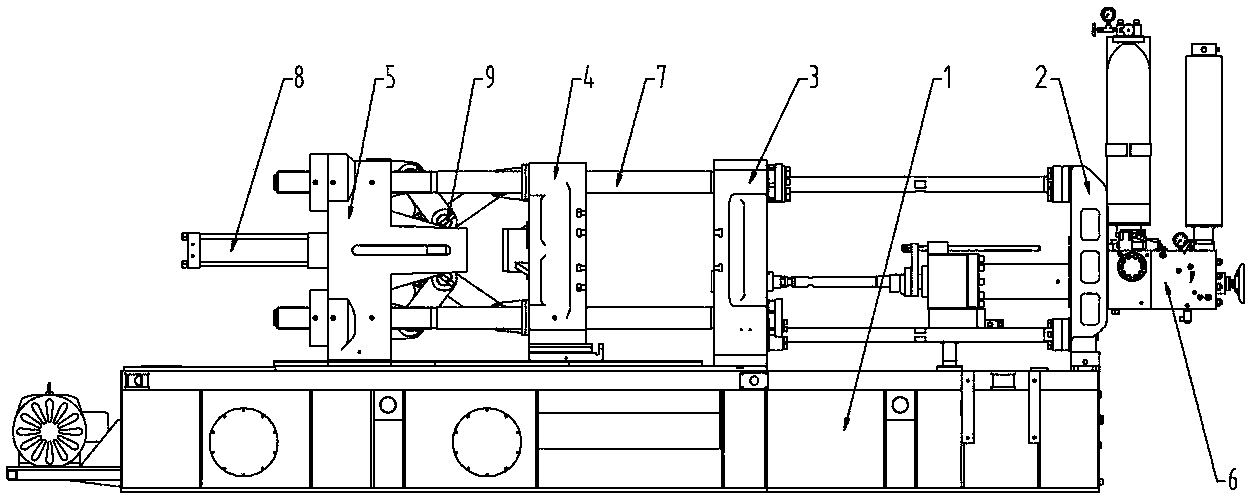

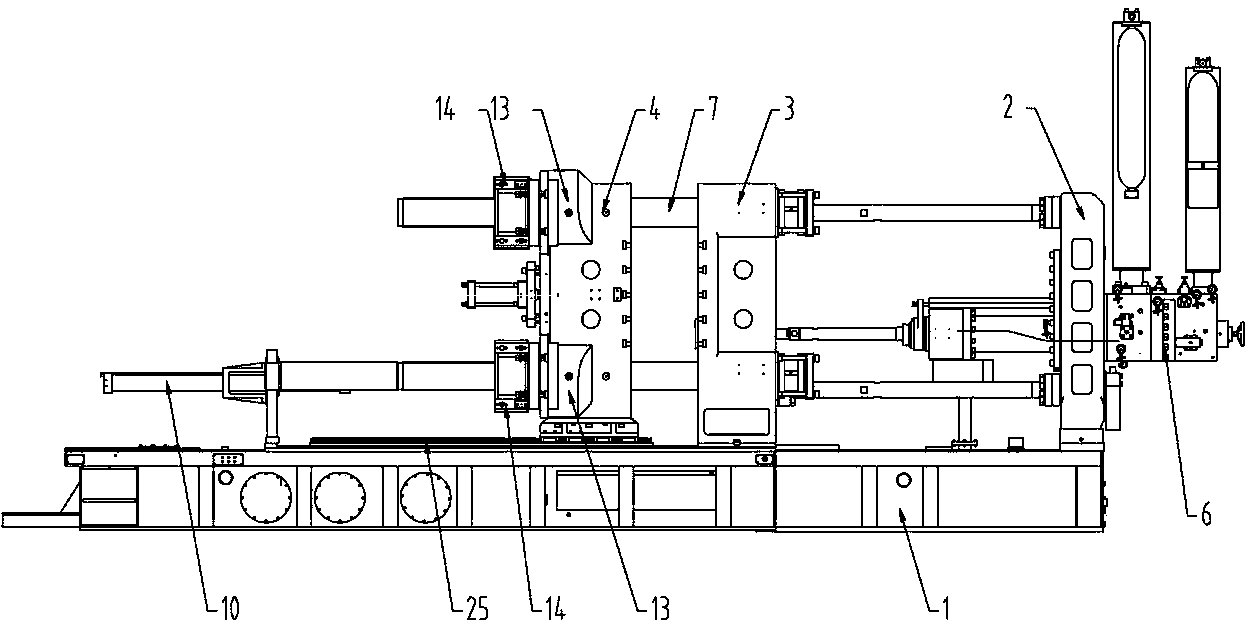

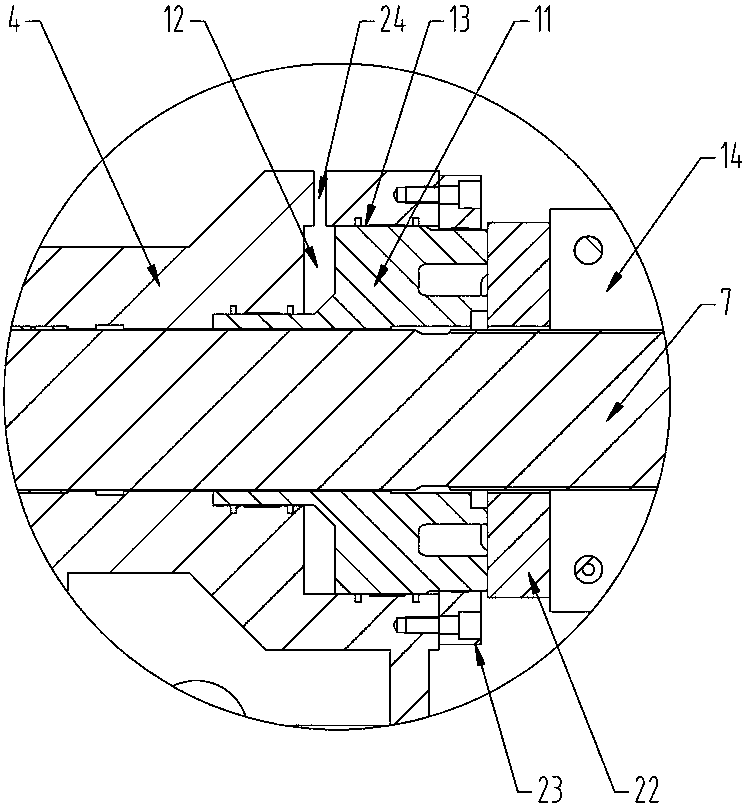

[0027] like Figure 2-5 Shown: a two-plate high-speed die-casting machine, including frame 1, gantry frame 2, static template 3, movable template 4, clamping cylinder 5 and injection mechanism 6, static template 3 and movable template 4 are set on On the frame 1, a linear guide rail 25 is installed on the frame 1, and a slider 26 that can slide on the linear guide rail 25 is provided at the bottom of the movable template 4; wherein the static template 3 and the movable template 4 are connected in series through four large bars 7 , a large bar hole for embedding the mold clamping piston 11 is provided at the position where the large bar 7 protrudes from the movable template 4, and the cavity between the front side of the mold clamping piston 11 and the inner cavity wall of the movable template 4 forms a hydraulic pressure Cavity 12, the hydraulic chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com