Low-pressure die casting machine with liftable and changeable heat preserving furnace

A technology of low pressure casting machine and heat preservation furnace, which is applied in the field of low pressure casting machine and low pressure casting machine of aluminum alloy wheel hub, can solve the problems of affecting the service life of products, being brought into the furnace body, and impure aluminum liquid, etc., so as to reduce labor intensity and increase Service life and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

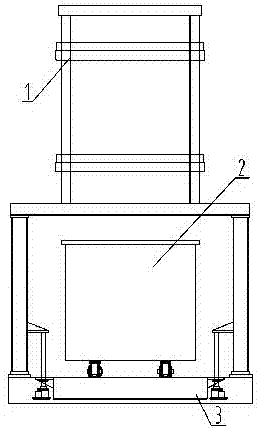

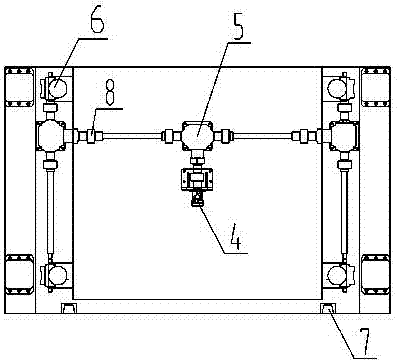

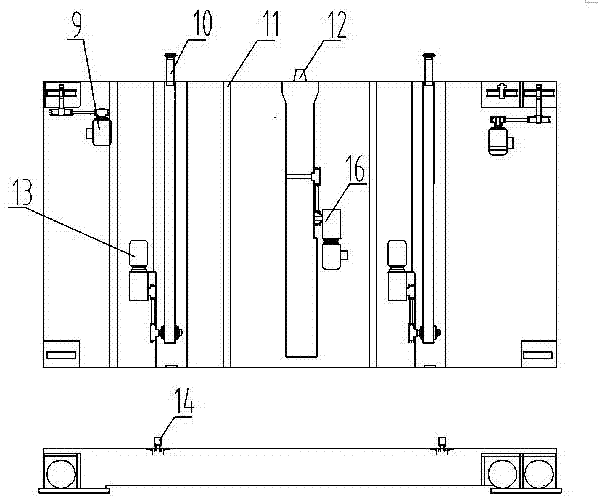

[0013] Depend on figure 1 , figure 2 Known, the low-pressure casting machine that the holding furnace can be lifted and replaced is composed of a low-pressure casting machine 1, a transfer trolley and a melting furnace 17. The low-pressure casting machine 1 is provided with a lifting mechanism and a holding furnace 2, and the transfer trolley and the low-pressure casting machine 1 and the smelting furnace 17 are arranged in parallel, and the transfer trolley is used to transport the empty solid aluminum liquid holding furnace from the smelting furnace 17 to the casting machine 1. The lifting mechanism is composed of a lifting platform 3, a frequency conversion reduction motor 4, a cross steering gear 5, The worm gear 6, the positioning slot 7 and the guide rail 8 of the machine holding furnace, the lifting platform 3 is arranged under the platen of the low pressure casting machine 1, and the frequency conversion reduction motor 4 and the machine holding furnace guide rail are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com