Method for mfg. aluminium alloy wheel hub

A technology of an aluminum alloy wheel hub and a manufacturing method, which is applied to the manufacturing field of the aluminum alloy wheel hub, can solve the problems that the density and strength of the aluminum alloy wheel hub cannot be further improved, the investment cost of low-pressure casting equipment is high, and the power of the hydraulic pump is large, and the equipment investment cost is reached. and maintenance costs are reduced, surface treatment workload is small, and energy consumption is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

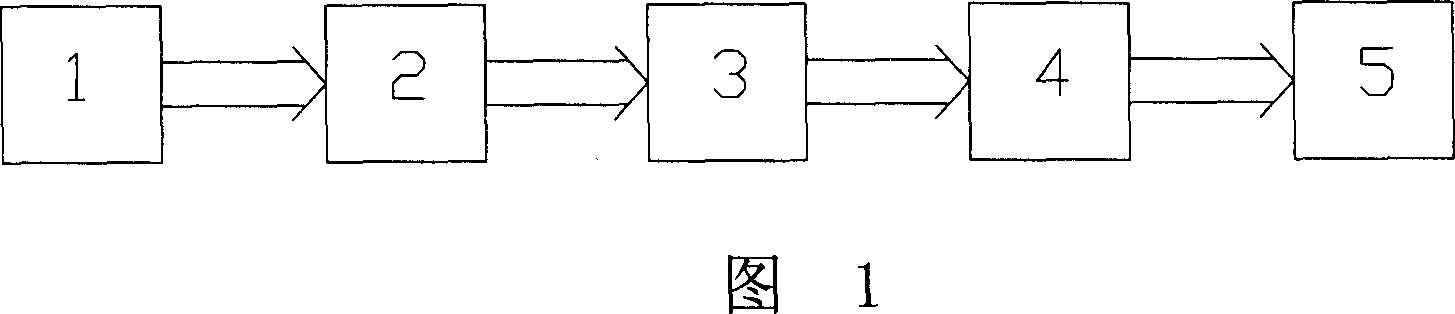

[0021] As shown in Figure 1: the manufacturing method of the aluminum alloy wheel hub of the present embodiment, comprises the following steps:

[0022] 1. Heat the aluminum alloy material to make the aluminum alloy material melt;

[0023] 2. The molten aluminum alloy material is poured into the casting mold from the gate of the casting mold. There is a feeding allowance area in the casting mold, and the molten aluminum alloy material fills the casting mold under the action of gravity;

[0024] 3. After the molten aluminum alloy material fills the casting mold, the molten aluminum alloy material is left in the feeding allowance area, and external pressure is applied to the feeding allowance area, and the external pressure exerts pressure on the molten aluminum alloy in the casting mold;

[0025] 4. Cool the casting mold and the aluminum alloy in the casting mold to form the rough blank of the wheel hub;

[0026] 5. Process the rough blank of the wheel hub to make the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com