Casting method of aluminum alloy wheel rim

A technology for aluminum alloys and rims, which is applied in the field of manufacturing aluminum alloy rims, can solve the problems of increasing manufacturing costs, and achieve the effects of low cost, simple shape, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

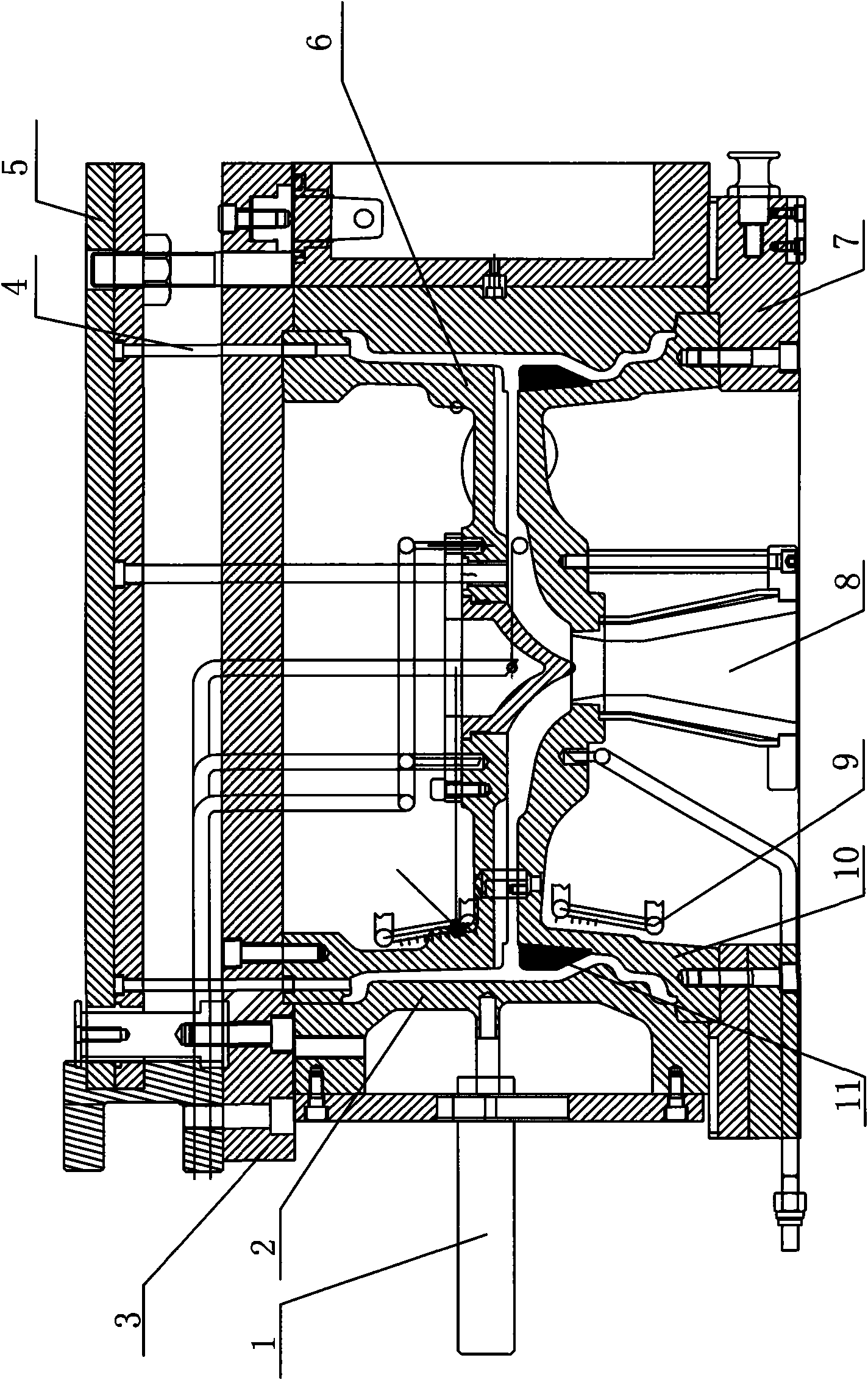

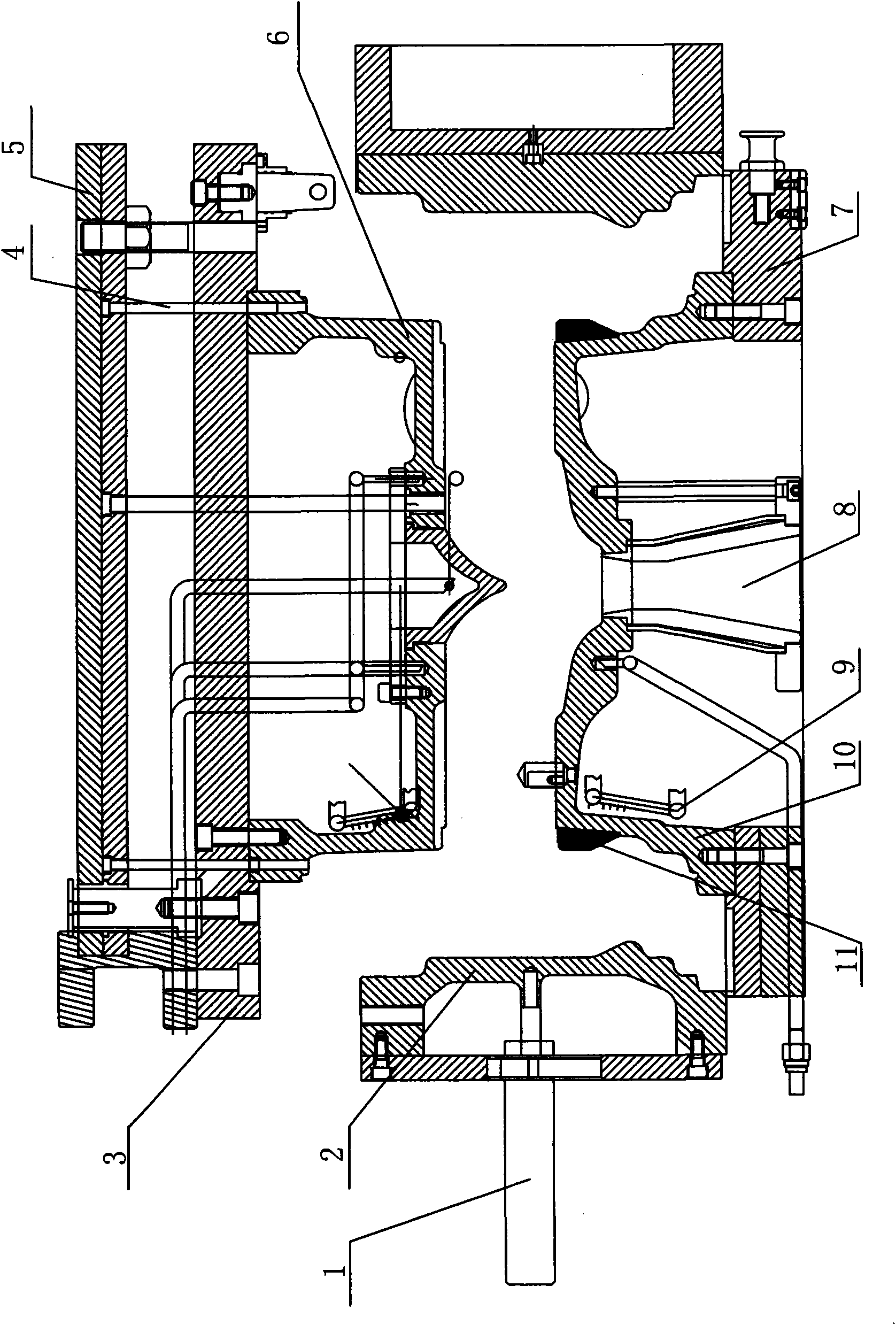

[0021] Embodiment: make the aluminum alloy wheel rim with the method for low-pressure casting.

[0022] Production steps:

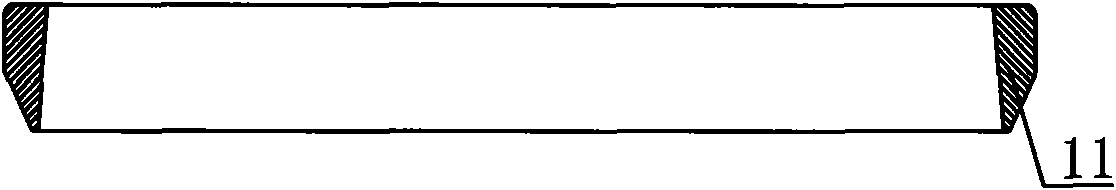

[0023] 1) Material selection: A356 aluminum ingots are used as raw materials to produce aluminum alloy rims. At the same time, the same A356 aluminum ingots are used as raw materials to make aluminum alloy rings 11 by gravity casting, and put the aluminum alloy rings 11 into an oven to preheat Keep warm at 390-410°C without spraying mold agent on it. The inner hole of the aluminum alloy ring has a taper of 15-25 degrees, and the lower end of the outer surface has a taper that matches the demoulding slope of the aluminum alloy wheel hub produced;

[0024] 2) Put the A356 aluminum ingot into the melting furnace and heat it up to 740-760°C, then pour the aluminum water into the crucible and put in Mg / Sr / Ti and other alloys, and use nitrogen degassing for refining;

[0025] 3) Preheat the metal mold for low-pressure casting to 400-450°C, and then directly pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com