Forging process of large aluminum alloy hub

A technology of aluminum alloy wheels and aluminum alloys, which is applied in the directions of wheels, push-out equipment, transportation and packaging, etc., can solve the problems of inability to protect the health of workers, health hazards of operators, and poisoning of human bodies, so as to improve safety and work Efficiency, reduction of production time, effects of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

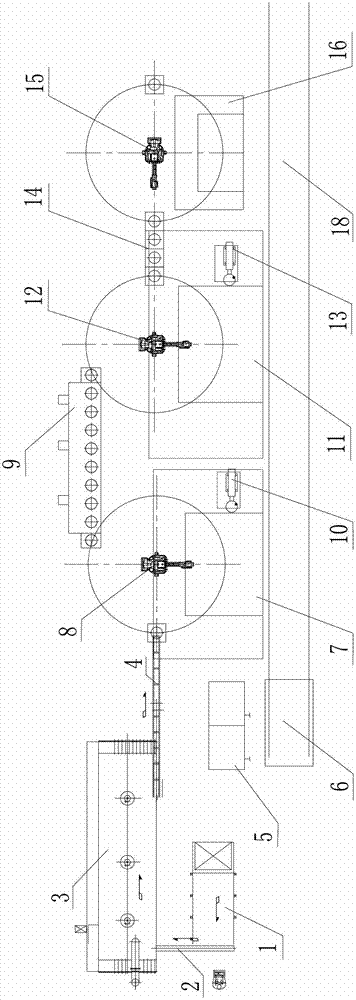

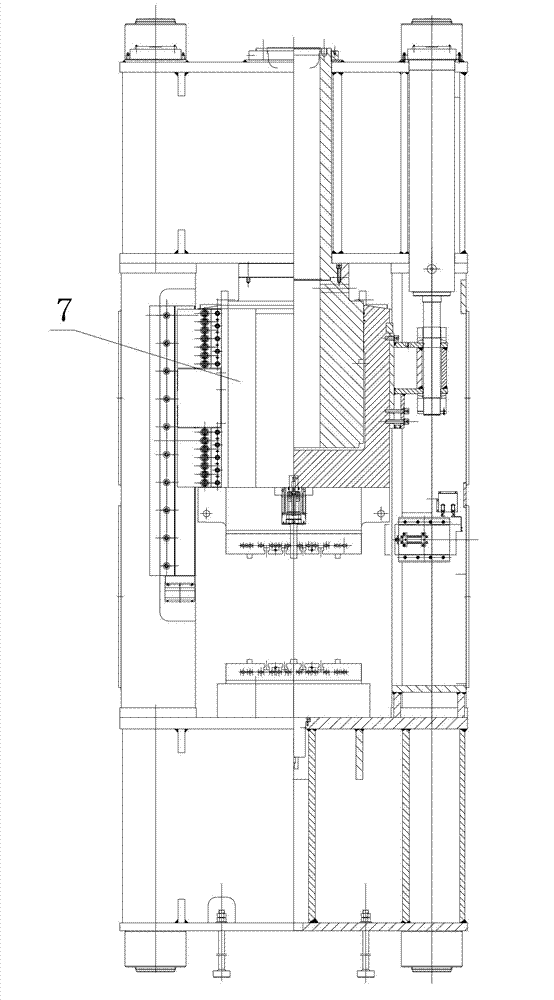

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

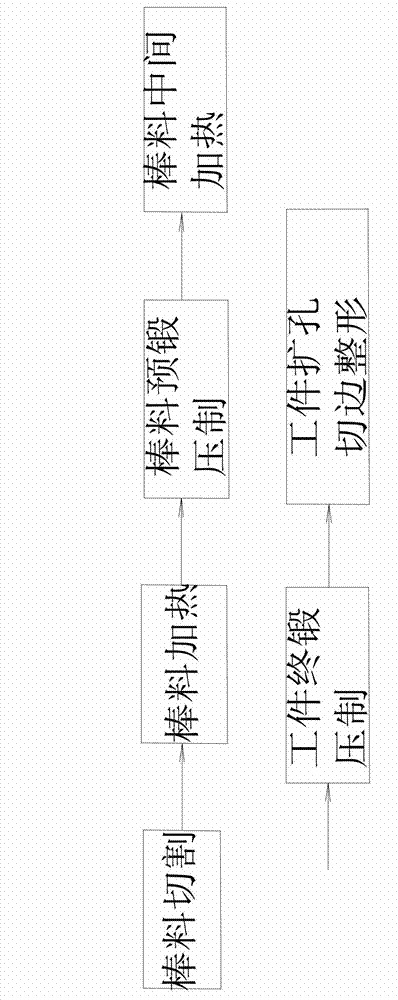

[0035] see Figure 1-Figure 6 , large-scale aluminum alloy wheel hub forging process, using the processing technology of a large-scale aluminum alloy hub forging production line, including the following steps:

[0036] 1) Cut the aluminum alloy bar according to the set length;

[0037] 2) The cut aluminum alloy bar is placed in a bar heating furnace for heating;

[0038] 3) The heated aluminum alloy billet is pre-forged and pressed by a pre-forging hydraulic press;

[0039] 4) The pre-forged workpiece is sent to the intermediate heating furnace for secondary heating and heat preservation;

[0040] 5) Send the heated and heat-preserved workpiece into the wheel hub final forging hydraulic press for final forging and pressing;

[0041] 6) Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com