Coke powder binder, coke balls suitable for production in closed calcium carbide furnaces and preparation method thereof, method for producing calcium carbide in closed calcium carbide furnaces

An adhesive and calcium carbide furnace technology, which is applied in the directions of starch adhesives, adhesive types, polymer adhesive additives, etc. There are no problems such as actual economic value when the proportion is low, and the effect of simple pressing process and low cost of ball production is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

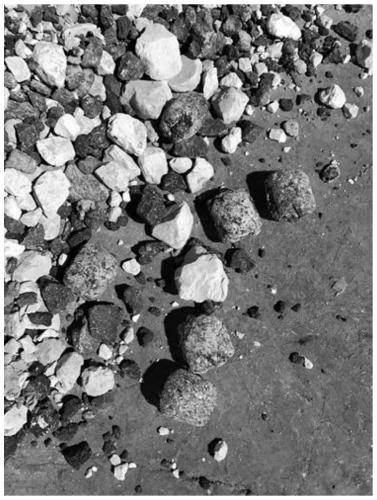

Image

Examples

Embodiment 1

[0039] Prepare the focal sphere as follows:

[0040] (1) Feeding coke powder and coke powder binder according to the ratio of 100:3 to obtain a mixture; the properties of the coke powder: ash content 12.4%, volatile matter 3.6%, fixed carbon 84%, average particle size 3.7mm; The coke powder binder consists of the following components: 60% corn starch, 20% closed electrode paste, 10% petroleum coke, 5% coal tar, and 5% carburant.

[0041] (2) Use a vertical mixer to fully stir the mixture, add water to the mixture while stirring to humidify the mixture, the mass ratio of the mixture to water is 100:16, and then heat the humidified material to 80 ℃, to obtain the material to be pressed.

[0042] (3) Press the material to be pressed into shape with a briquetting machine, and the pressing pressure is 0.4 MPa to obtain a molding material, and the particle size of the molding material is about 34 mm.

[0043] (4) The molded material is dried to a water content of 1.0% by using hot...

Embodiment 2

[0046] Prepare the focal sphere as follows:

[0047] (1) Feeding coke powder and coke powder binder according to the ratio of 100:3.3 to obtain a mixture; the properties of the coke powder: 12.4% ash content, 3.6% volatile matter, 84% fixed carbon, and an average particle size of 3.7mm; The coke powder binder is composed of the following components: 64% corn starch, 18% closed electrode paste, 9% petroleum coke, 4% coal tar, and 5% carburant.

[0048] (2) Use a vertical mixer to fully stir the mixture, add water to the mixture while stirring to humidify the mixture, the mass ratio of the mixture to water is 100:20, and then heat the humidified material to 65 ℃, to obtain the material to be pressed.

[0049] (3) The material to be pressed is pressed into shape with a briquetting machine, and the pressing pressure is 0.5 MPa to obtain a molding material, and the particle size of the molding material is about 40 mm.

[0050] (4) The molded material is dried to a moisture conten...

Embodiment 3

[0053] Prepare the focal sphere as follows:

[0054] (2) Feeding coke powder and coke powder binder according to the ratio of 100:3.5 to obtain a mixture; the properties of the coke powder: 12.4% ash content, 3.6% volatile matter, 84% fixed carbon, and an average particle size of 3.7mm; The coke powder binder is composed of the following components: cornstarch 56%, closed electrode paste 22%, petroleum coke 10%, coal tar 6%, carburant 6%.

[0055] (2) Use a vertical mixer to fully stir the mixture, and add water to the mixture while stirring to humidify the mixture. The mass ratio of the mixture to water is 100:15, and then the humidified material is heated to 70 ℃, to obtain the material to be pressed.

[0056] (3) The material to be pressed is pressed into shape with a briquetting machine, and the pressing pressure is 0.3 MPa to obtain a molding material, and the particle size of the molding material is about 18 mm.

[0057] (4) The molded material is dried to a moisture c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com