A thermal insulation material for synthesizing large-grain diamond

A thermal insulation material and diamond technology, which is applied in the field of thermal insulation materials for synthesizing large-grained diamonds, can solve the problems of lack of thermal insulation materials, synthesis devices that cannot reach the temperature, and difficulties in synthesizing large-grained diamonds, and achieve wide sources of raw materials, simple components, and Guaranteed temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

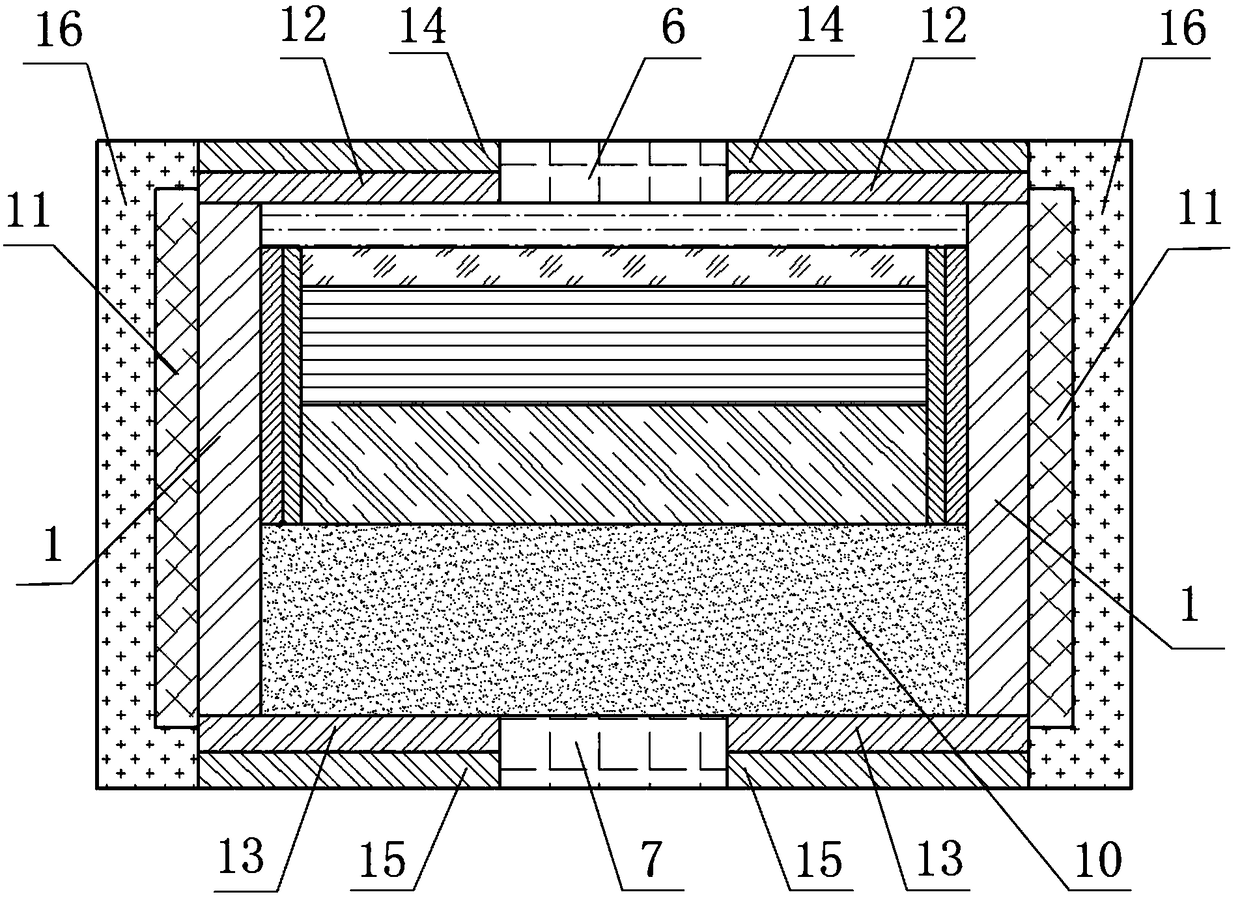

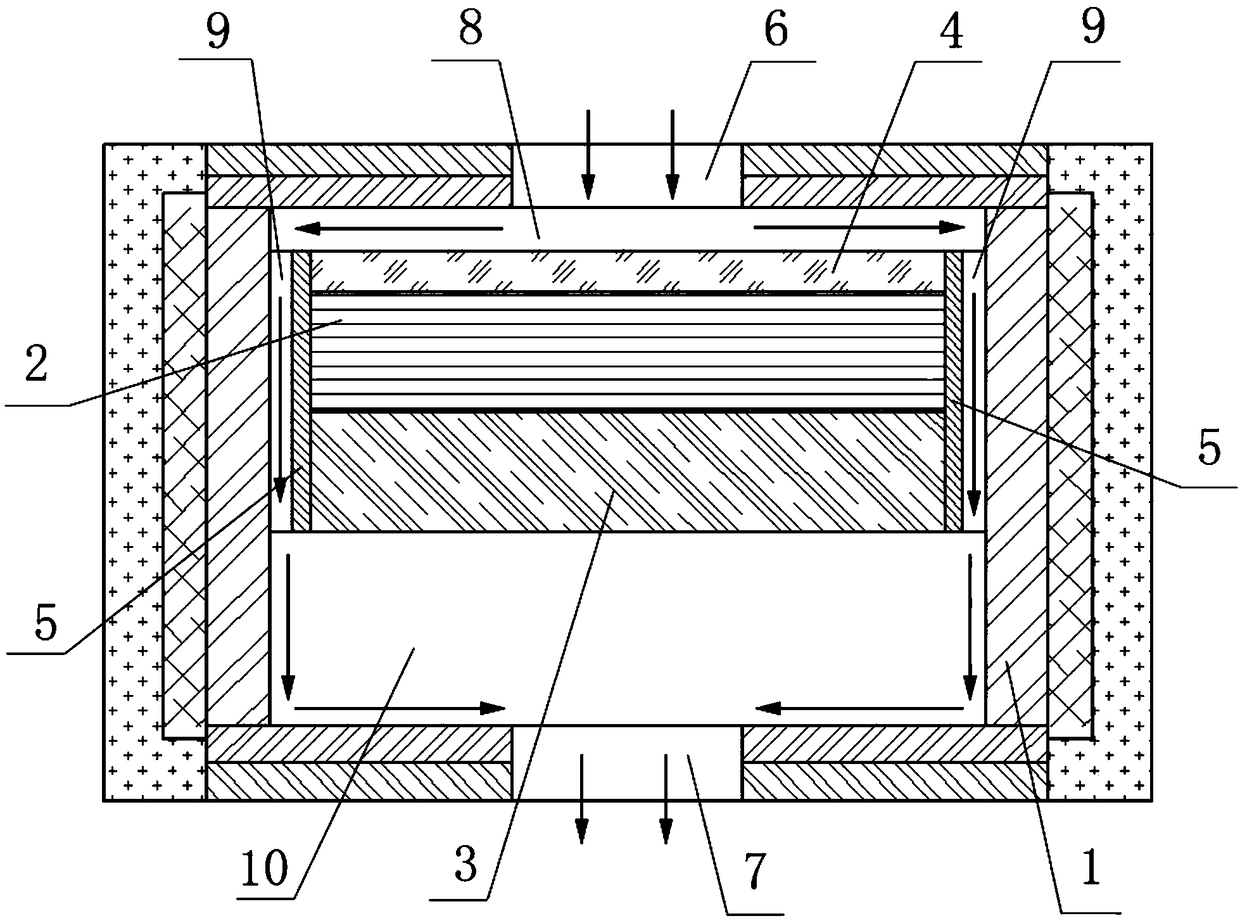

[0026] Such as figure 1 Shown is the structural representation of the large-grain diamond synthesis device in the present invention; as figure 2 Shown is a schematic diagram of the current flow during the synthesis process of the large-grain diamond synthesis device in the present invention. A device for synthesizing large-grain diamonds provided by the present invention includes a diamond generating unit, a conductive component unit, a sealing unit, a heat preservation unit and a black body 1 .

[0027] The diamond generating unit includes a first graphite piece 2 , a metal catalyst 3 , a first heat preservation component 4 , and a second heat preservation component 5 . The top of the first graphite piece 2 is in contact with the first heat preservation component 4, and the bottom end of the first graphite piece 2 is in contact with the metal catalyst 3. The first graphite piece 2, the metal catalyst 3 and the first heat preservation component 4 are all placed in the second...

Embodiment 2

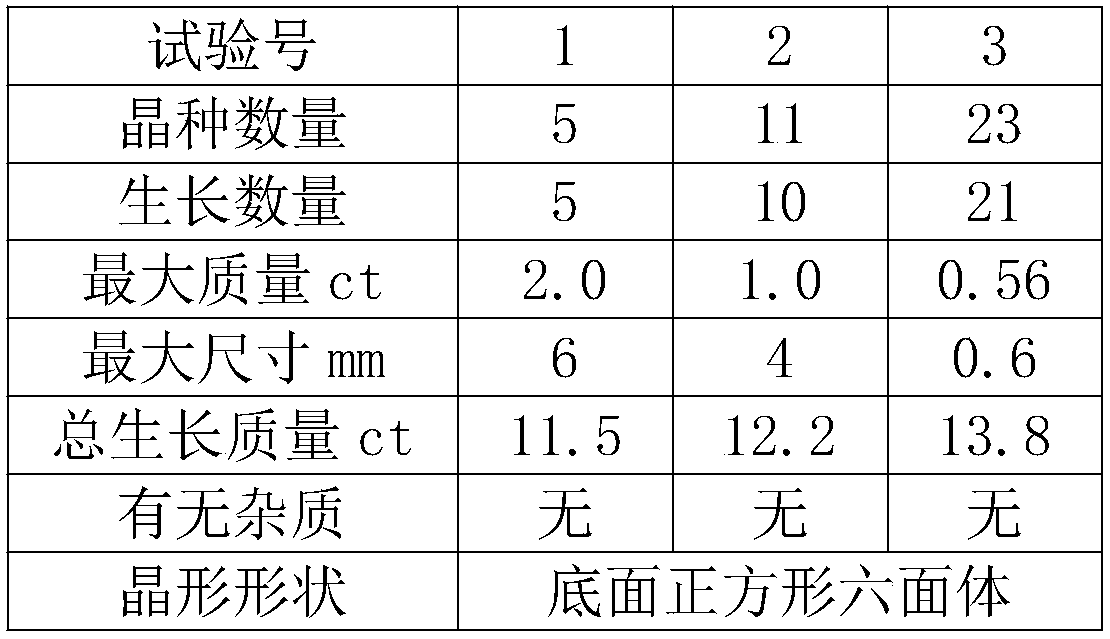

[0049] The difference between this embodiment and Embodiment 1 is that the thermal insulation material components used in the third thermal insulation component 11, the fourth thermal insulation component 12 and the fifth thermal insulation component 13 are composed of two high temperature resistant solid metal halide salts and titanium dioxide, Wherein the high temperature resistant solid metal halide salt can be sodium bromide or sodium iodide or potassium iodide or potassium bromide. The preferred two high temperature resistant solid metal halide salts in this embodiment are sodium bromide and sodium iodide, the first high temperature resistant solid metal halide salt is sodium bromide, and the second high temperature resistant solid metal halide salt is iodide Sodium, the first high-temperature-resistant solid metal halide salt, the second high-temperature-resistant solid metal halide salt and titanium dioxide are mixed and compressed according to the weight ratio of 2:2:1 ...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the thermal insulation material components used in the third thermal insulation component 11, the fourth thermal insulation component 12 and the fifth thermal insulation component 13 are composed of two high temperature resistant solid metal halide salts and titanium dioxide, Wherein the high temperature resistant solid metal halide salt can be sodium bromide or sodium iodide or potassium iodide or potassium bromide. The preferred two high temperature resistant solid metal halide salts in this embodiment are sodium bromide and sodium iodide, the first high temperature resistant solid metal halide salt is sodium bromide, and the second high temperature resistant solid metal halide salt is iodide Sodium, the first high-temperature-resistant solid metal halide salt, the second high-temperature-resistant solid metal halide salt and titanium dioxide are mixed and compressed according to a weight ratio of 3:2:1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com