Pneumatic striking device for hub broaching and trimming press

A technology of trimming and wheel hub, applied in forging/pressing/hammer devices, operating devices, metal processing equipment, etc., can solve the problems of wasting manpower, material and financial resources, unable to meet the processing technology, hidden dangers of production safety, etc. The effect of fast speed, improved safety and work efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

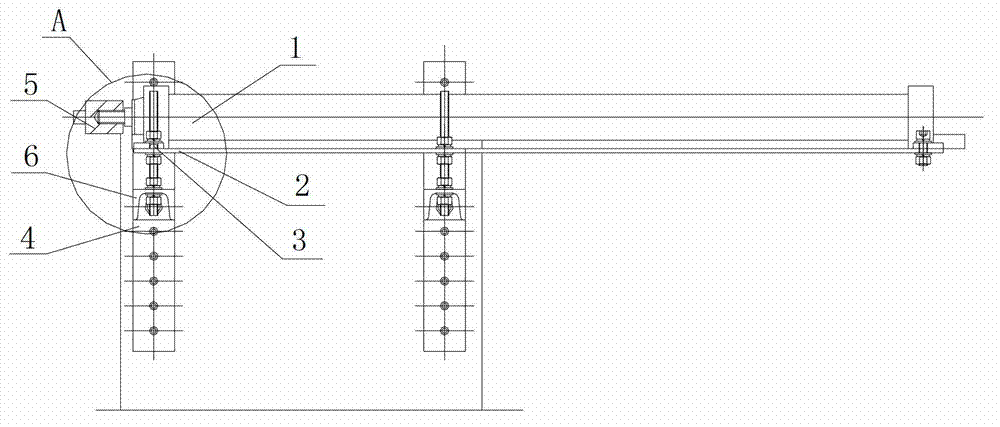

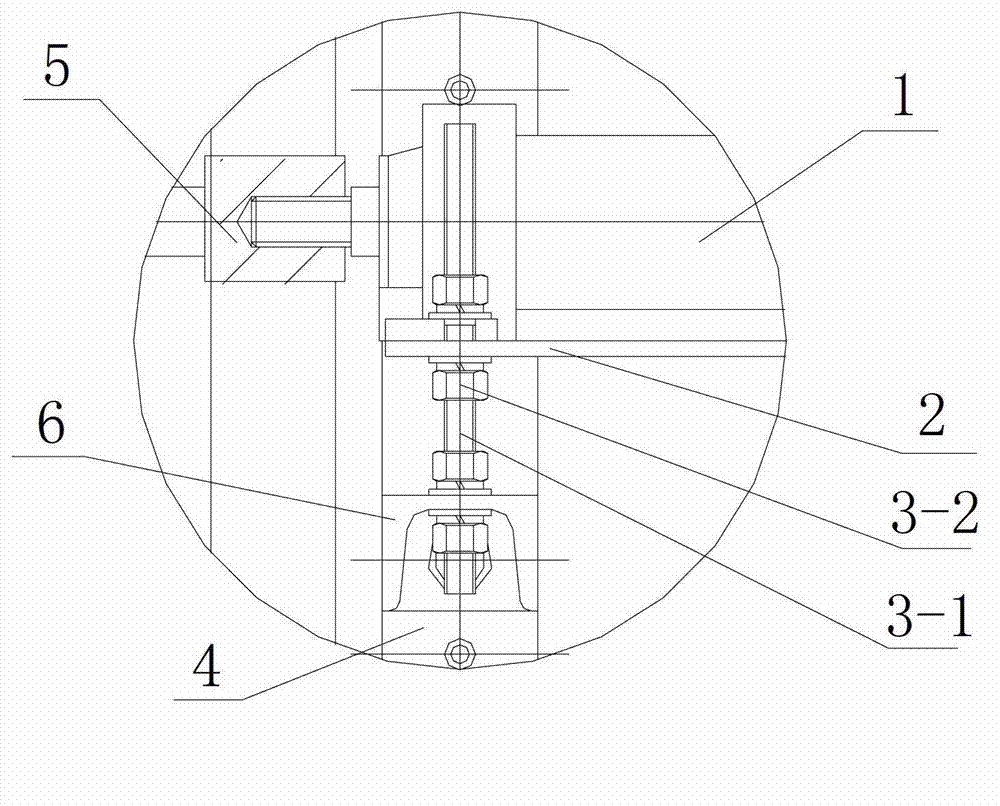

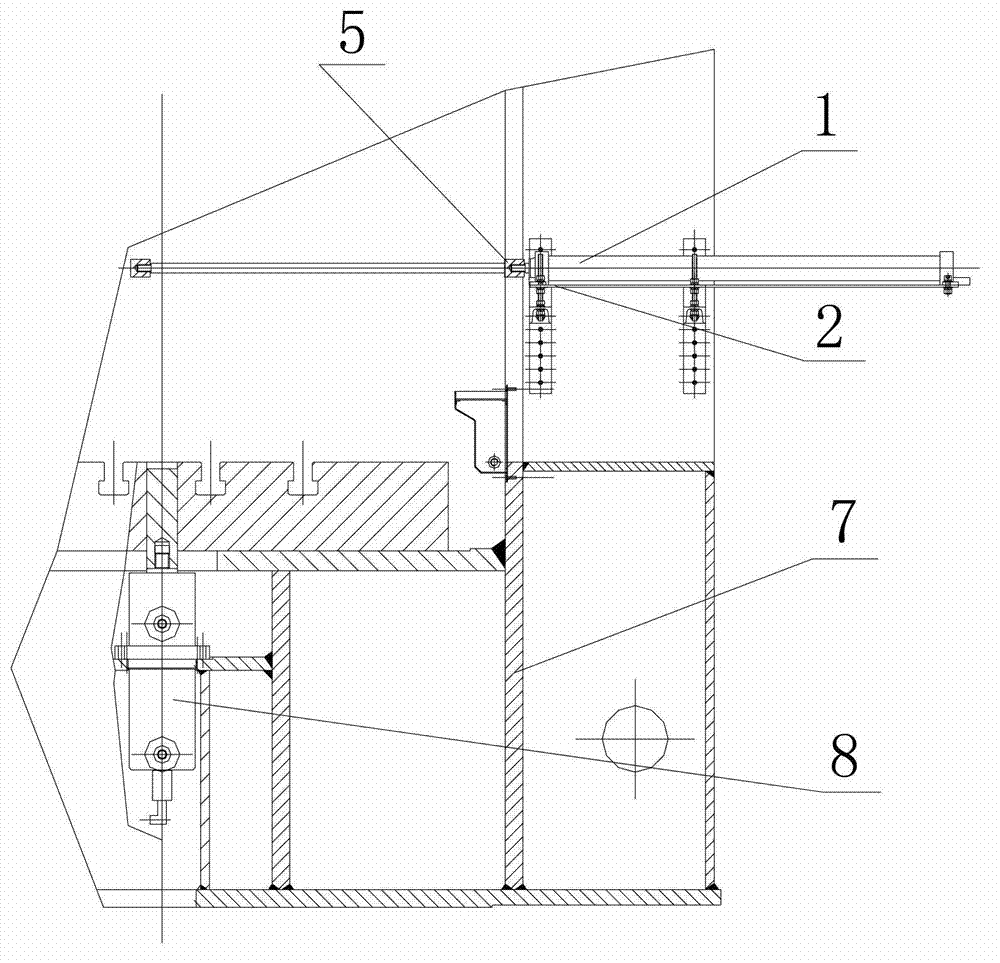

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see Figure 1-Figure 3 , the pneumatic feeding device of the wheel hub reaming and edge trimming press, including the bracket 6 installed on the inside of the fuselage pillar 7 and the fixed distance adjustment plate 4 connected thereto, through the bracket 6 and the fixed distance adjustment plate 4, the fixed distance of equal distance can be realized. distance adjustment. The height fine-tuning mechanism 3 that can realize micro-distance adjustment is housed on the described support, and the feeding cylinder 1 that one end is connected with the support 6 is also equipped with on this side of the described pillar, and the front end of the feeding cylinder is connected with the feeding head 5 . In this embodiment, the fixed distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com