Low-pressure casting process and device for aluminum alloy wheel by bilateral pouring

A technology of low-pressure casting and aluminum alloy, which is applied in the field of low-pressure casting double-side pouring technology and devices for aluminum alloy wheels, can solve problems such as shrinkage of R corners at the intersection of spokes and rims, low mechanical properties of wheels, and influence on mechanical properties of wheels, etc., to achieve Good mechanical properties, easy operation, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are given below in conjunction with the accompanying drawings.

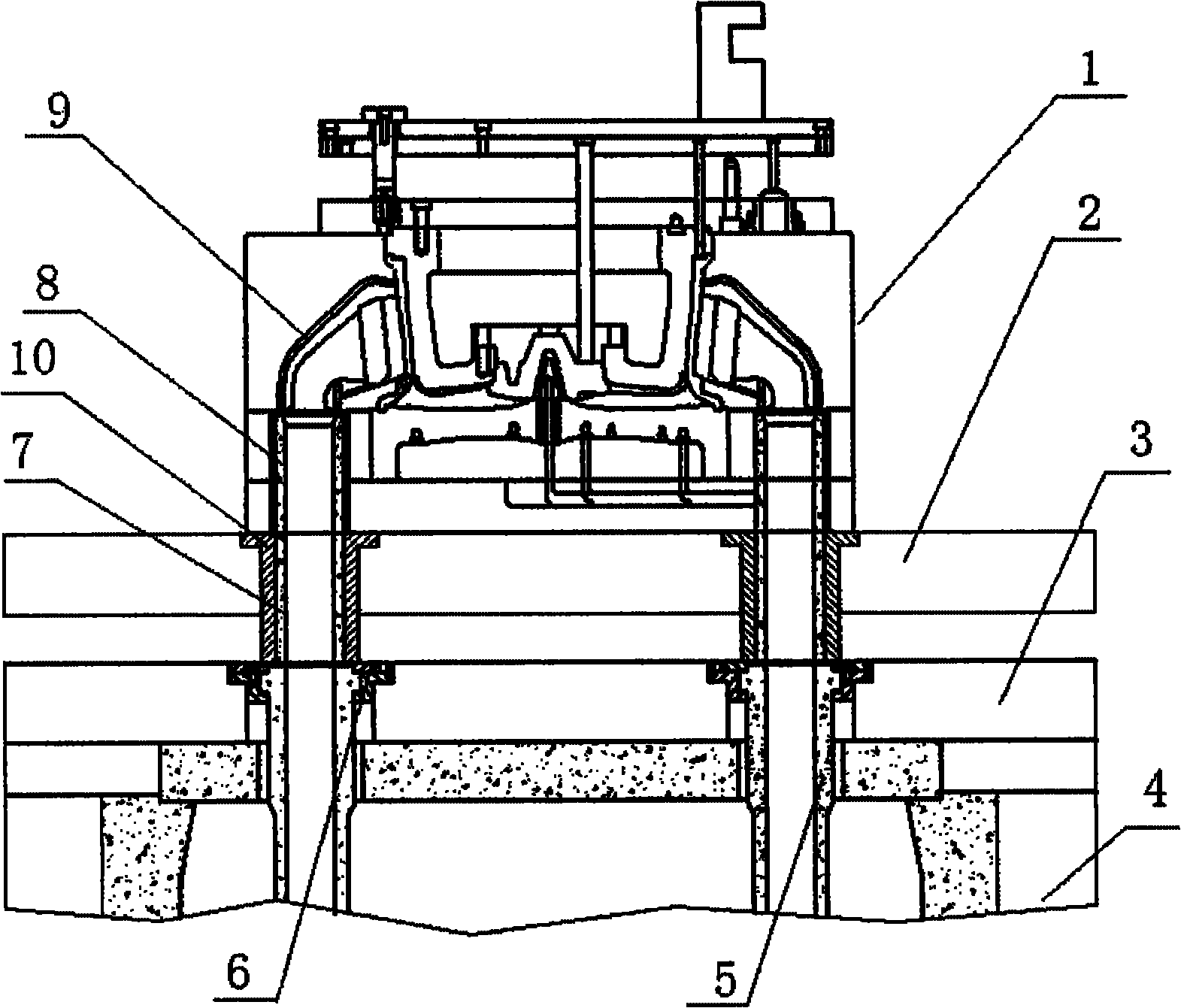

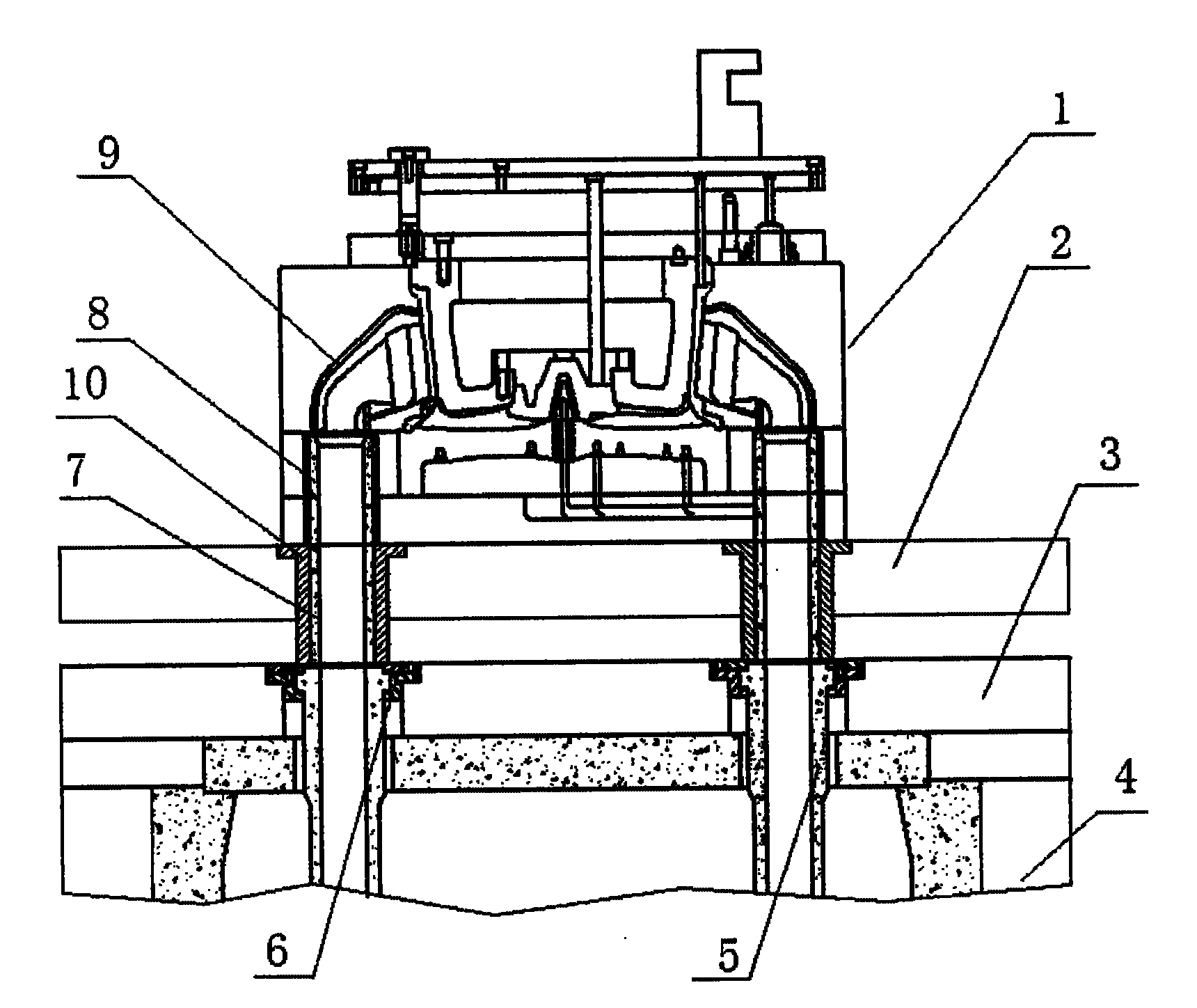

[0034] refer to figure 1 , the aluminum alloy wheel low-pressure casting device of the present invention includes a cooling system, a temperature control system, a molding system and a demoulding system, and is characterized in that the casting device includes a double-sided casting mold 1, and the double-sided casting mold 1 is assembled on the machine table 2 Above, below the machine platen 2 is the cover 3 of the low-pressure holding furnace. The cover 3 of the low-pressure holding furnace is assembled on the body 4 of the holding furnace. The liquid pipe 8 is arranged at the water inlet position of the double-sided casting mold 1 .

[0035] In order to ensure smooth aluminum liquid flow channel and easy maintenance and replacement, a platen suction pipe 7 is separately provided on the machine platen 2 .

[0036] The top mold and the bottom mold of the low-pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com