Forging and rotary extrusion forming process for aluminium alloy wheel

A forming process and technology of aluminum alloy, which is applied in the field of forging-spinning process of forging aluminum alloy wheels, and can solve the problems of complicated hot spinning process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

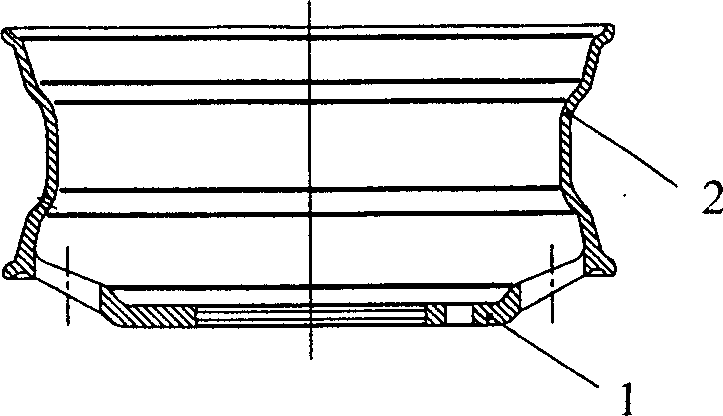

[0010] Such as figure 1 As shown, the aluminum alloy wheel is composed of a spoke 1 and a rim 2.

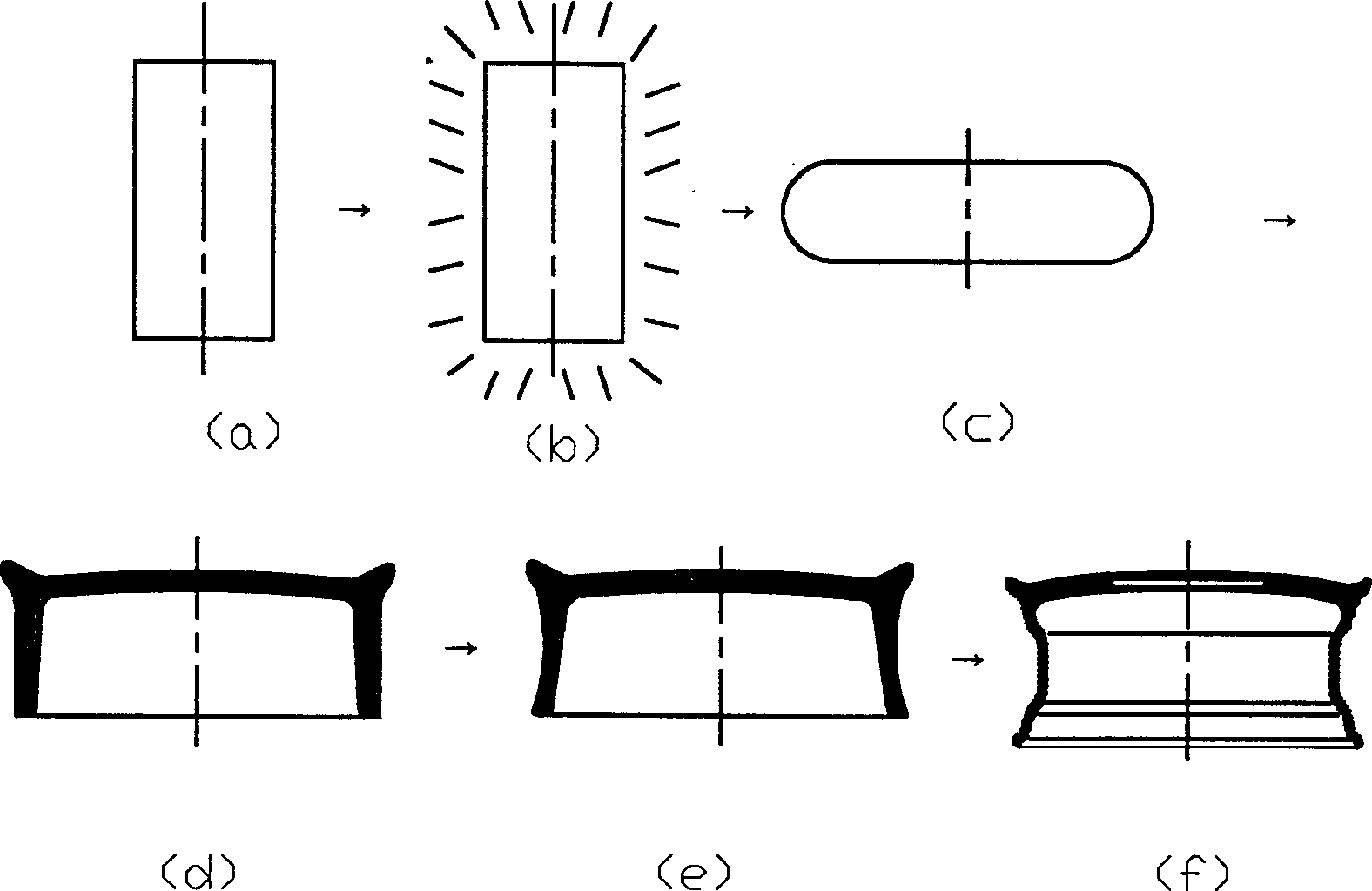

[0011] Such as figure 2 As shown, the forging process described in the forging-spin forming process of this forged aluminum alloy wheel includes the following steps: a, blanking: sawing the aluminum alloy bar into a blank according to the principle of constant volume; b, heating: cutting the blank Heating to the forging temperature; c, upsetting: upsetting the heated billet with a press; d, die forging: placing the upset billet in a die forging die for die forging; e, shaping: forging The finished blank is placed in the shaping die for shaping. The spinning process is as follows: f. After annealing the shaped blank, use a spinning machine to spin the rim part until the overall wheel forming is completed.

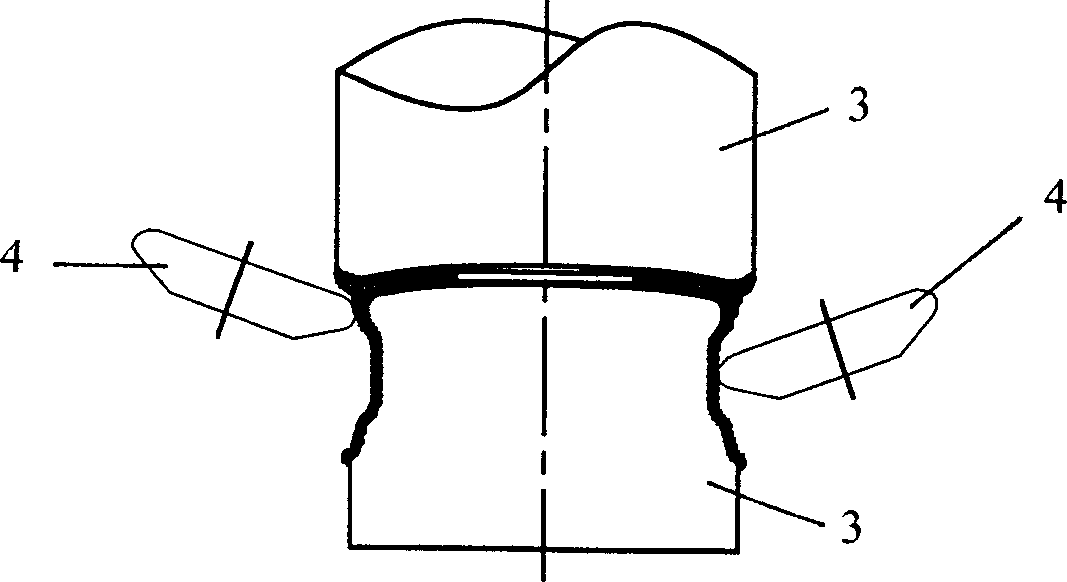

[0012] Such as image 3 As shown, in the spinning process, the spinning mold 3 used is in two halves, and the two halves are inserted from both ends of the blank and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com