Coating method of aluminum alloy wheel rim

A coating method and technology of aluminum alloy, which is applied to the device for coating liquid on the surface, wheel rim, coating, etc., can solve the problems of aluminum alloy wheel rim lack of metal texture, prone to color difference, high energy consumption, etc., to achieve Guarantee the smoothness and brightness of the product, reduce production costs, and relax the effect of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the coating method of the aluminum alloy wheel rim of the present invention are given below, but the implementation of the present invention is not limited to the following embodiments.

[0030] In order to comply with the development trend of auto parts production, high-gloss silver paint is applied to the paint spraying of aluminum alloy wheel rims to make the surface of the product smooth and bright, replacing the electroplating process, on the basis of ensuring the quality and appearance of aluminum alloy wheel rims Above all, reducing the impact on the environment.

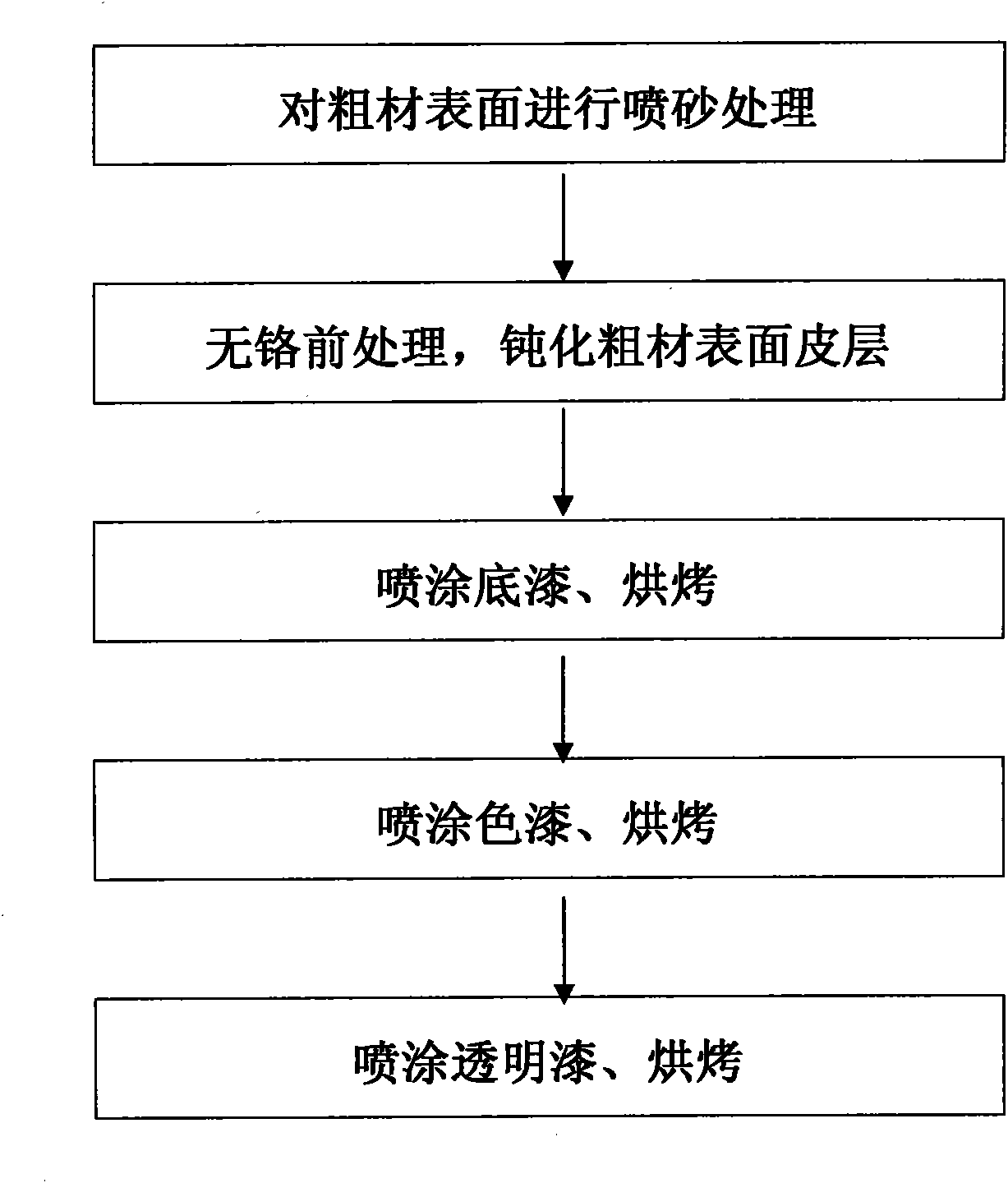

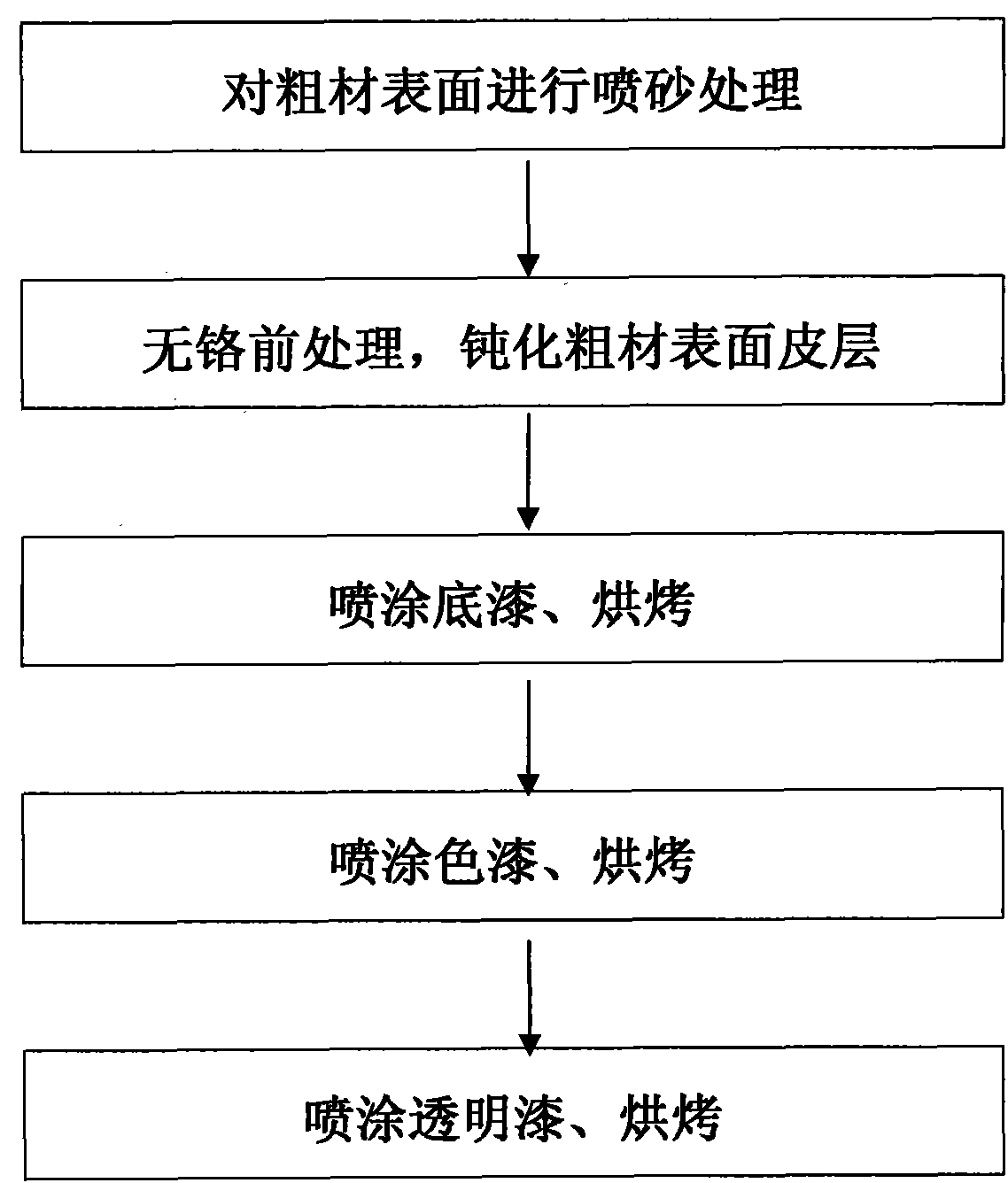

[0031] A coating method for an aluminum alloy wheel rim, using high-gloss silver paint as the coating paint, and its production steps are:

[0032] (1) Sandblasting the surface of the rough material: use 0.4mm diameter steel balls to sand the surface of the rough material to make the surface roughness uniform;

[0033] (2) Chromium-free pre-treatment: Passivate the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com