Olivine-added lightweight ceramsite sand and preparation process thereof

A light-weight ceramsite and preparation process technology, applied in ceramic products, drilling compositions, other household appliances, etc., to achieve the effect of saving energy, improving crystal structure, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

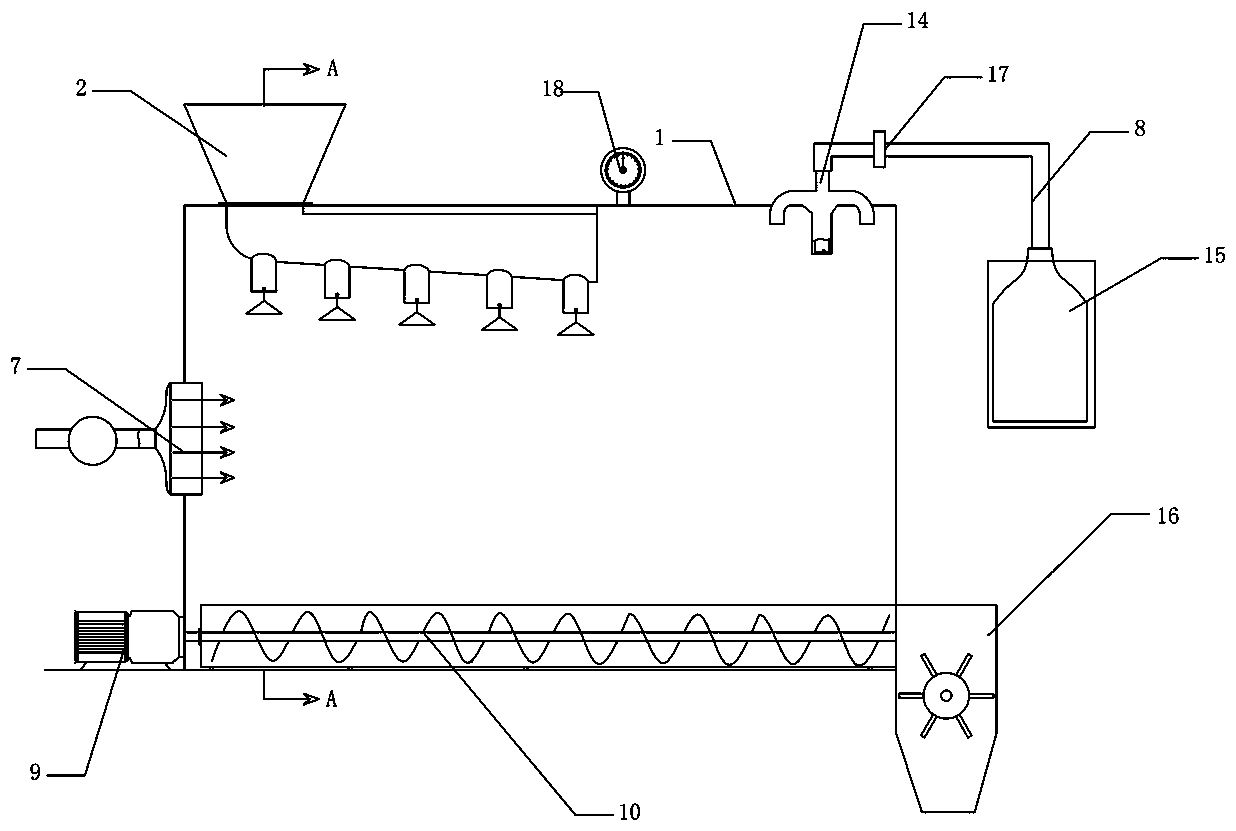

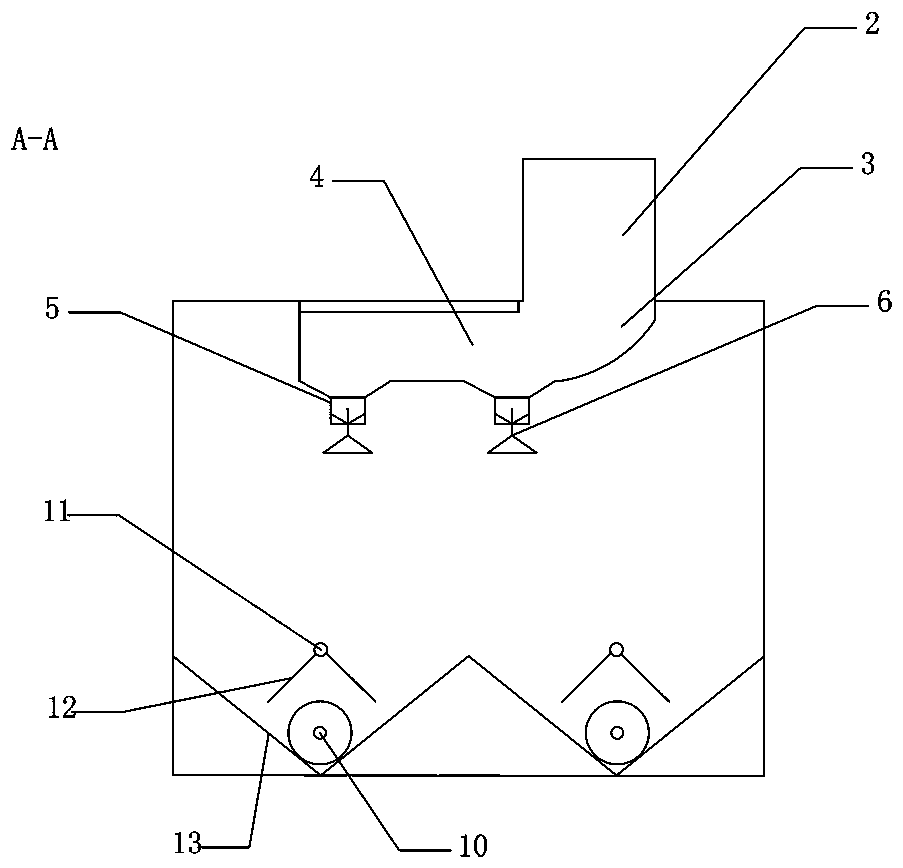

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: This embodiment provides a ceramsite sand with olivine added, including the following raw materials in weight percentage: bauxite 45wt%, burnt gem 40wt%, olivine 7wt%, magnesium slag 3wt%, manganese ore powder 5wt% .

[0034] Preparation Process:

[0035] Step 1. Ingredients: Weigh the bauxite, burnt gem and olivine according to weight percentage, pour them into a ball mill for grinding and pass through a 325-400 mesh sieve, then grind the magnesium slag and manganese ore powder through a 400 mesh sieve.

[0036]Step2. Mixing and granulation: Pour the sieved powder into the mixer and mix at a speed of 1800-2000 r / min for 10-30 minutes, then mix at a speed of 1200-1500 r / min for 10-30 minutes, and During the mixing process, 5% of the total weight of raw materials is sprayed into highly atomized water to obtain a mixture, and the mixture is sent to a granulator for granulation, and semi-finished embryos of different particle sizes are obtained after passing...

Embodiment 2

[0046] Embodiment 2: On the basis of Embodiment 1, a kind of ceramsite sand with olivine added in this embodiment, the difference is that the raw materials used are bauxite 50wt%, burnt gemstone 35wt%, olivine 10wt%, magnesium Slag 3wt%, manganese ore powder 2wt%.

[0047] Preparation Process:

[0048] Step 1. Ingredients: Weigh bauxite, burnt gem and olivine according to weight percentage, pour them into a ball mill for grinding and pass through a 325 mesh sieve, then grind the magnesium slag and manganese ore powder through a 400 mesh sieve.

[0049] Step2. Mixing and granulation: Pour the sieved powder into the mixer and mix at a speed of 1800-2000 r / min for 10-30 minutes, then mix at a speed of 1200-1500 r / min for 10-30 minutes, and During the mixing process, 5% of the total weight of raw materials is sprayed into highly atomized water to obtain a mixture, and the mixture is sent to a granulator for granulation, and semi-finished embryos of different particle sizes are ob...

Embodiment 3

[0053] Example 3: The difference from Example 1 is that the ceramsite sand added with olivine provided in this example is different in that the raw materials used are bauxite 55wt%, burnt gem 30wt%, olivine 12wt%, Magnesium slag 2wt%, manganese ore powder 1wt%.

[0054] Preparation process: Step1, ingredients: Weigh bauxite, coke gem and olivine according to weight percentage, pour them into a ball mill for grinding and pass through a 325-400 mesh sieve, then grind magnesium slag and manganese ore powder through a 400 mesh sieve .

[0055] Step2. Mixing and granulation: Pour the sieved powder into the mixer and mix at a speed of 1800-2000 r / min for 10-30 minutes, then mix at a speed of 1200-1500 r / min for 10-30 minutes, and During the mixing process, 5% of the total weight of raw materials is sprayed into highly atomized water to obtain a mixture, and the mixture is sent to a granulator for granulation, and semi-finished embryos of different particle sizes are obtained after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com