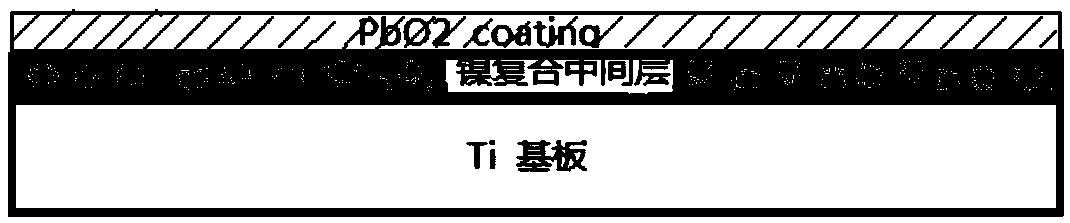

Method for preparing novel titanium-based Pb O2 anode with low energy consumption and long service life by adding nickel composite intermediate layer

A composite intermediate layer and low energy consumption technology, applied in chemical instruments and methods, electrolytic inorganic material coating, water/sludge/sewage treatment, etc., can solve the problems of cumbersome process, short working life, and limited engineering practicality, etc. The effect of high catalytic activity, extended service life, and simplified cumbersome links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

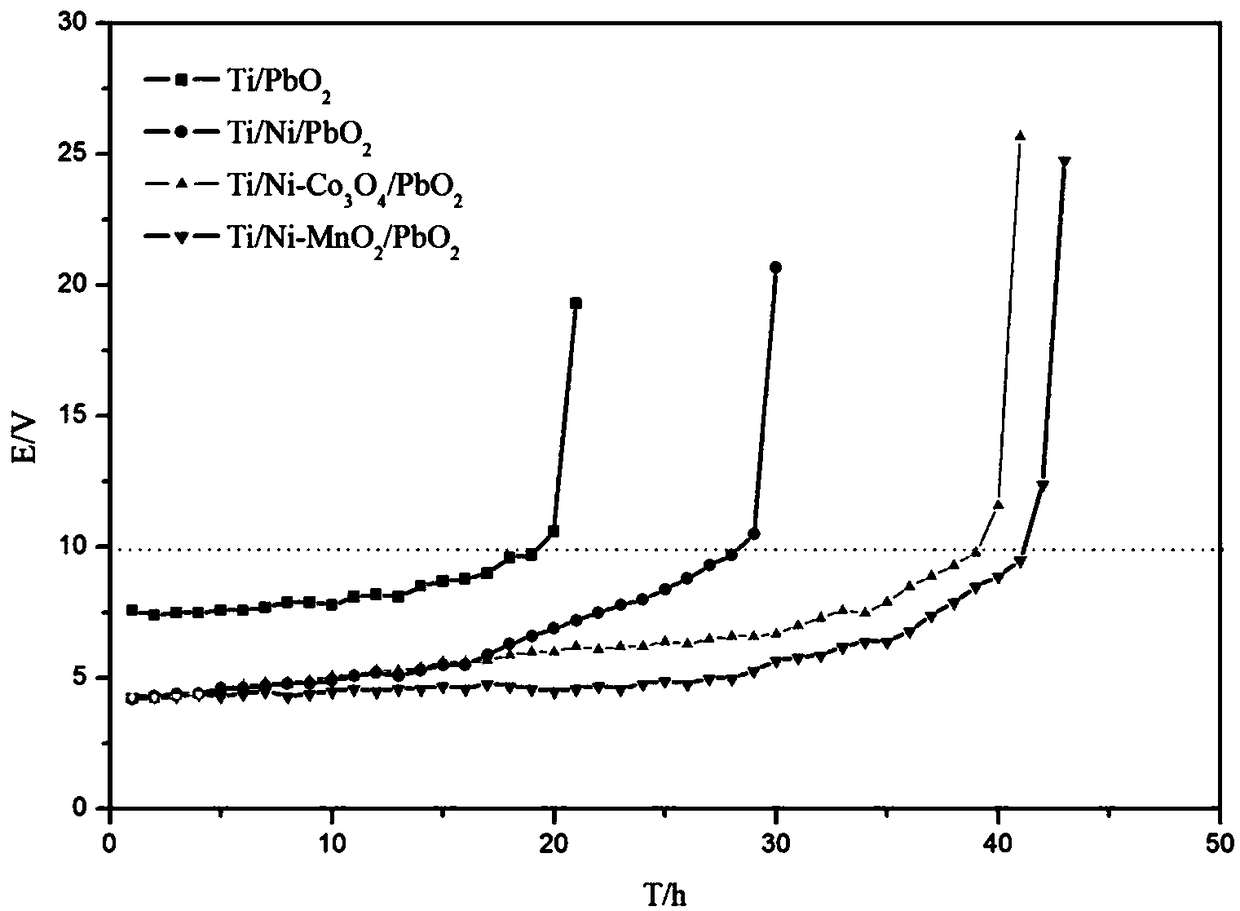

Embodiment 1

[0018] Firstly, the polished, alkali-washed and pickled titanium plate is used as the cathode, and the nickel plate of equal area is used as the anode, and the nickel composite intermediate layer is prepared by cathodic electrodeposition, and then Ti / Ni-Co 3 o 4 The electrode material is the anode, the stainless steel with the same size is the cathode, and the anode is electrooxidized to prepare β-PbO 2 active layer, thus obtaining Ti / Ni-Co 3 o 4 / PbO 2 shape stable anode. Ni-Co 3 o 4The electrodeposition conditions are: NiSO 4 ·7H 2 O180g / L, Na 2 SO 4 10H 2 O 65g / L, H 3 BO 3 30g / L, NaCl 10g / L, Co 3 o 4 (Particle size 5~10μm) 5g / L is electroplating nickel bath solution, the control temperature is 25±5℃, the electrodeposition time is 45min, and the current density is 2A / dm 2 , The pH value of the bath is 4.7. β-PbO 2 The electrodeposition conditions of the active layer are as follows: Pb(NO 3 ) 2 : 0.45mol / L, HNO 3 1.4mL / L, the pH value is 2.4, the ionic li...

Embodiment 2

[0020] Firstly, the polished, alkali-washed and pickled titanium plate is used as the cathode, and the nickel plate of equal size is used as the anode, and the nickel composite intermediate layer is prepared by cathodic electrodeposition, and then the Ti / Ni-MnO 2 The electrode material is the anode, the stainless steel with the same size is the cathode, and the anode is electrooxidized to prepare β-PbO 2 active layer, thus obtaining Ti / Ni-MnO 2 / PbO 2 shape stable anode. Ni-MnO 2 The electrodeposition conditions are: NiSO 4 ·7H 2 O180g / L, Na 2 SO 4 10H 2 O 65g / L, H 3 BO 3 30g / L, NaCl 10g / L, MnO 2 (Particle size 7~10μm) 5g / L is electroplating nickel bath solution, the control temperature is 25±5℃, the electrodeposition time is 45min, and the current density is 2A / dm 2 , The pH value of the bath is 4.7. β-PbO 2 The electrodeposition conditions of the active layer are as follows: Pb(NO 3 ) 2 : 0.45mol / L, HNO 3 1.4mL / L, the pH value is 2.4, the ionic liquid is 1-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com