Catalytic ozonation reactor for expanded bed and sewage treatment method of catalytic ozonation reactor

An ozone catalytic oxidation and reactor technology, which is applied in the oxidation water/sewage treatment and other directions, can solve the problems of affecting the treatment effect, increasing the difficulty of the reactor operation, and waste of ozone, so as to improve the mass transfer capacity and treatment effect, and reduce the difficulty of operation. And the effect of improving the level of automatic control and ozone utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

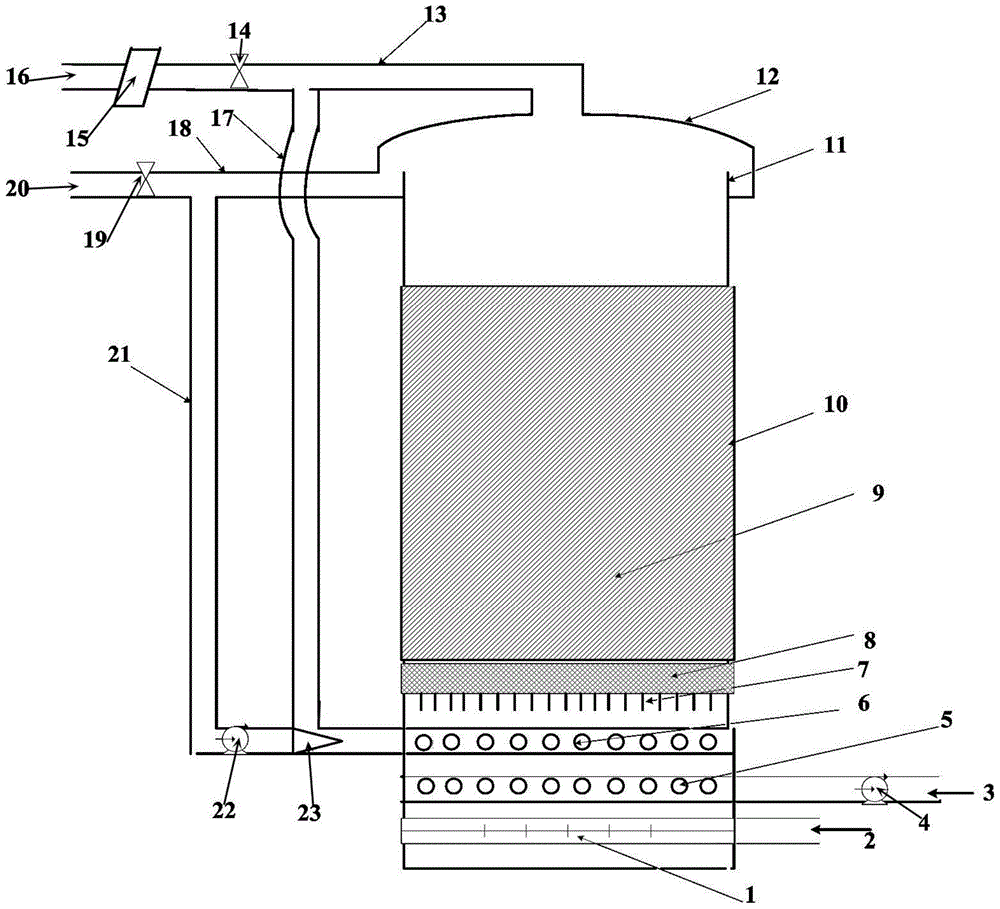

Method used

Image

Examples

Embodiment 1

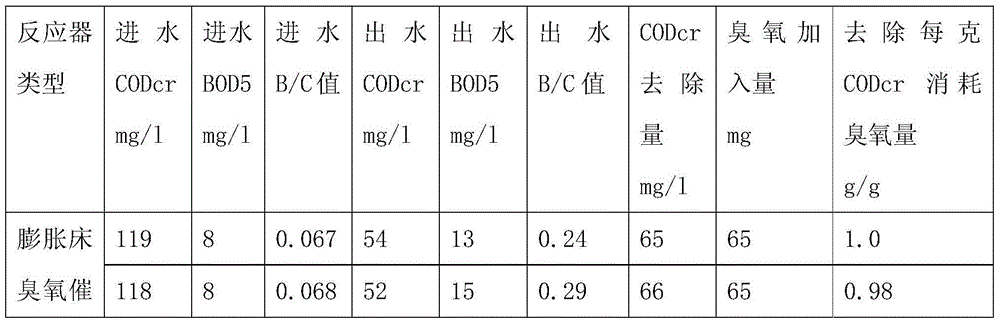

[0040] The COD of reverse osmosis concentrated water in a sewage reuse device is about 120mg / l. This stock of sewage was used as the test water. The comparative test results are shown in Table 1.

[0041] Table 1 Comparative test results of expanded bed ozone catalytic oxidation reactor and fixed bed ozone catalytic oxidation reactor

[0042]

[0043]

Embodiment 2

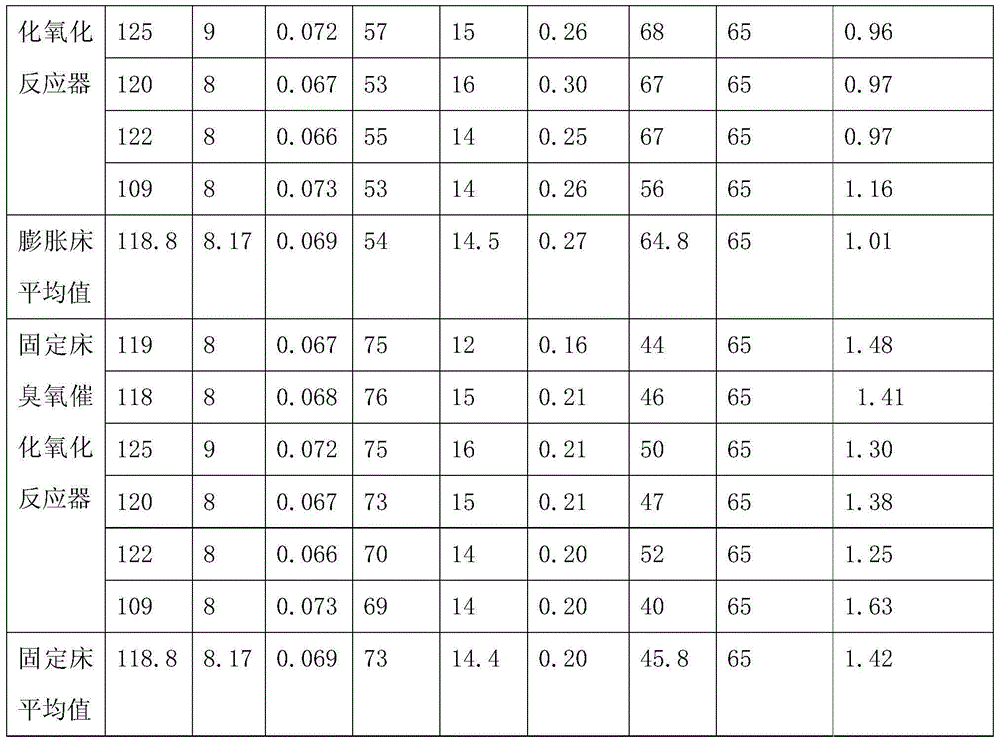

[0045] The CODcr of a certain chemical sewage is about 80mg / l, and this sewage is used as the test water. The comparison test results are shown in Table 2.

[0046] Table 2 Comparative test results of expanded bed ozone catalytic oxidation reactor and fixed bed ozone catalytic oxidation reactor

[0047]

[0048]

[0049] From the comparative test results in Table 1 and Table 2, it can be seen that the ozone utilization rate of the expanded bed ozone catalytic oxidation reactor has been greatly improved and the sewage treatment depth has been improved compared with the fixed bed ozone catalytic oxidation reactor. During the test period, the fixed-bed catalytic oxidation reactor was backwashed once every 6 days of operation, while the expanded-bed catalytic oxidation reactor was not backwashed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com