Hydraulic auto-oscillation control system for fire water monitor

A control system and technology for fire-fighting water cannons, which are used in fluid pressure actuating devices, fire rescue, servo motor assemblies, etc., can solve the problems of cumbersome structure of fire-fighting water cannons, unsuitable for fire fighting needs, etc. Maneuverable and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

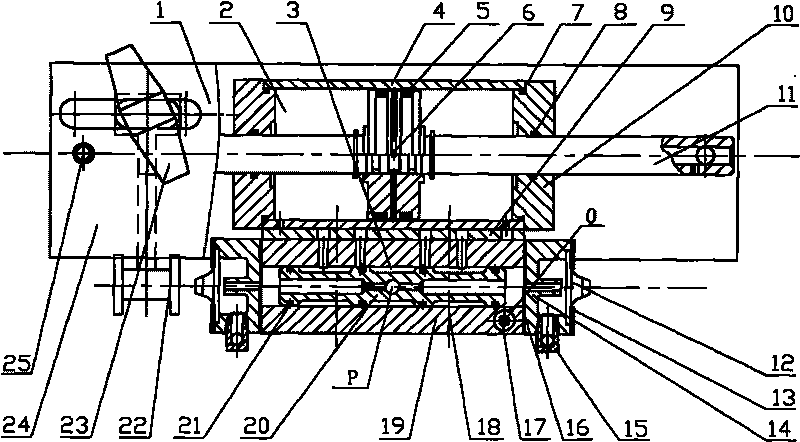

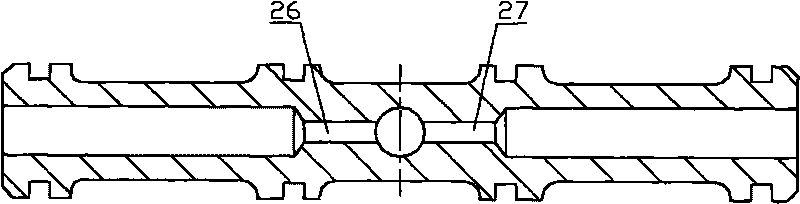

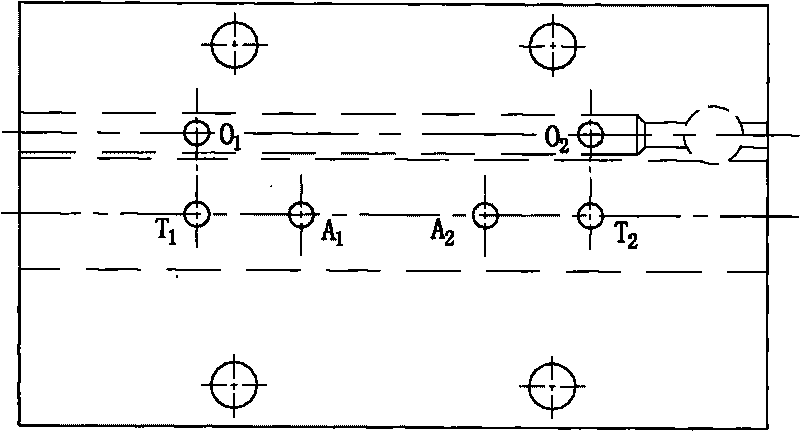

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes: water hydraulic cylinder 2, waterway backing plate 9, hydraulic reversing valve 3 and mechanical feedback device 1, wherein water hydraulic cylinder 2 is made up of cylinder body 4, piston sealing ring 5, piston 6, end cover sealing ring 7. Piston rod sealing ring 8, cylinder end cover 10 and piston rod 11, hydraulic reversing valve 3 consists of head 12, pressure plate 13, positioning end cover 14, screw plug 15, end cover gasket 16, piston pin 17 , valve body 19, valve core 20 and valve core sealing ring 21, mechanical feedback device 1 is composed of collision block 22, adjustment handle 23, transmission bracket 24 and direct pin 25; piston rod 11 is installed in the center hole of piston 6, and The two ends of the central hole of the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com