Fiber clock deep filter for reclaiming sewage

A technology of depth filter and fiber reuse, applied in distributor, choke ring and fiber cloth filter material, sieve plate, screw propeller field, can solve the problems of weakening strength and hot water resistance, and reduce investment cost and operating costs, improving filtration accuracy, and improving economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

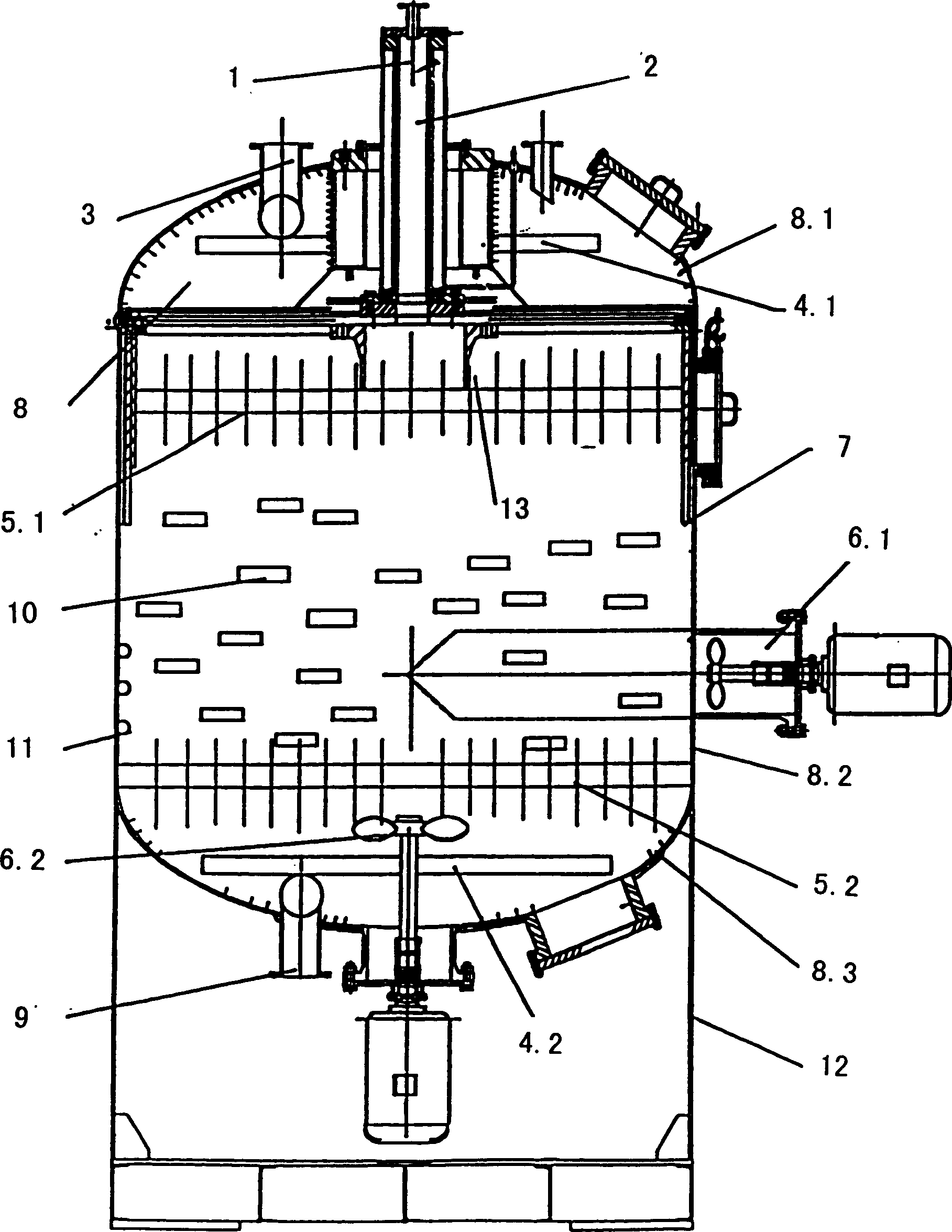

[0045] Below in conjunction with accompanying drawing and embodiment describe in detail:

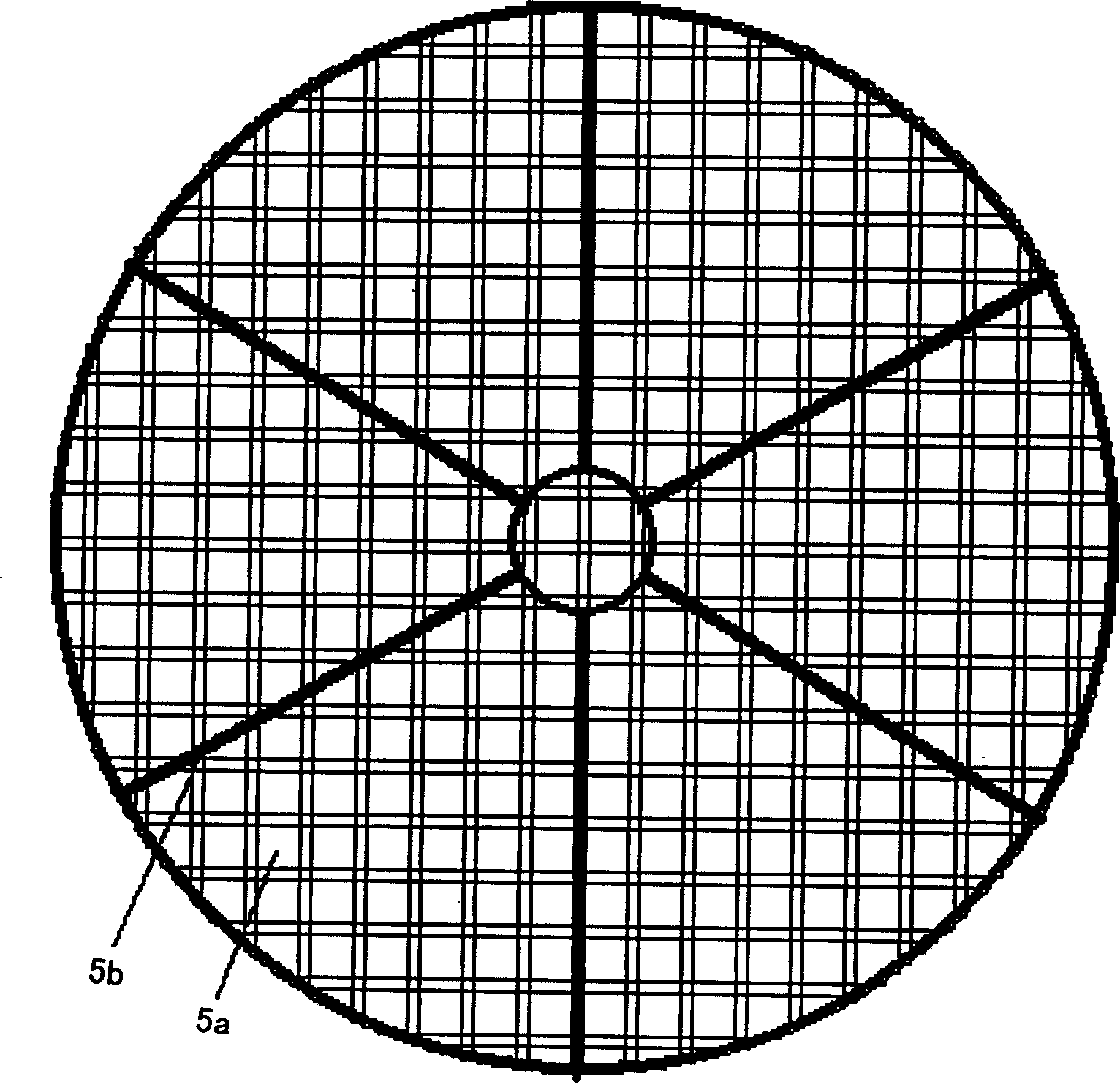

[0046] Depend on figure 2 It can be seen that the sieve plate 5 is composed of square sieve holes 5a and ribbed plates 5b; 3-6 ribbed plates 5b are equiangularly distributed on the square sieve holes 5a. The square sieve hole 5a is a uniquely designed square sieve hole without cutting process.

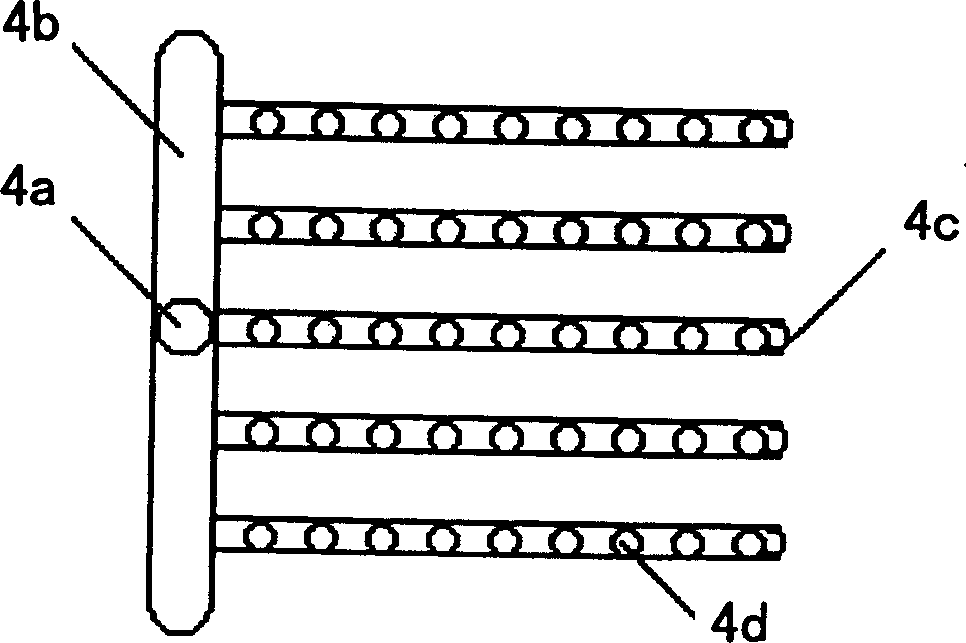

[0047] Depend on image 3 It can be seen that the distributor 4 is composed of a main water inlet pipe 4a, a water inlet pipe 4b, and a liquid distribution pipe 4c, which are connected in sequence; there is a small hole 4d on the liquid distribution pipe 4c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com