Well completion method for glass fiber reinforced plastic sieve tube of coal bed gas horizontal well

A screen tube completion and glass fiber reinforced plastic technology, which is used in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve problems such as difficulty in running the completion screen tube, small coal seam pressure relief area, explosion, etc. The effect of solving the accident of fly ash blocking the pump, improving the supporting capacity and the large pressure relief area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

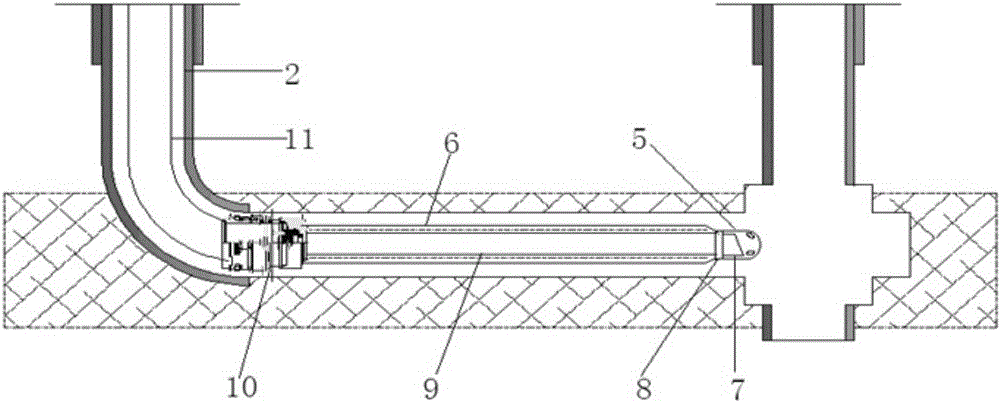

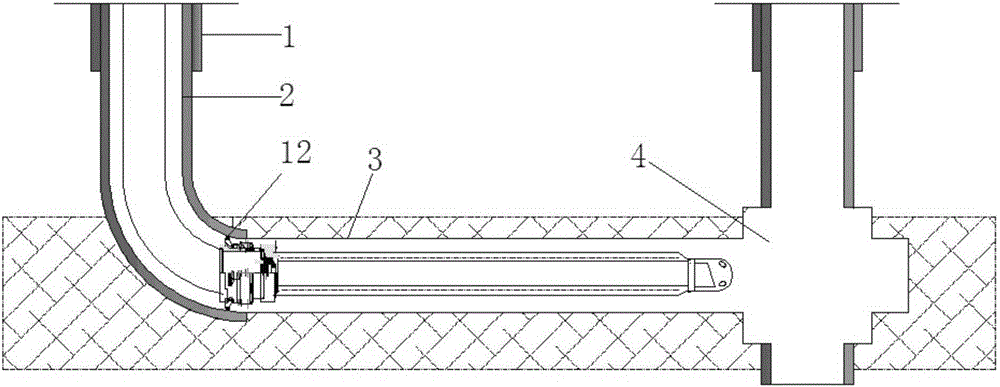

[0052] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

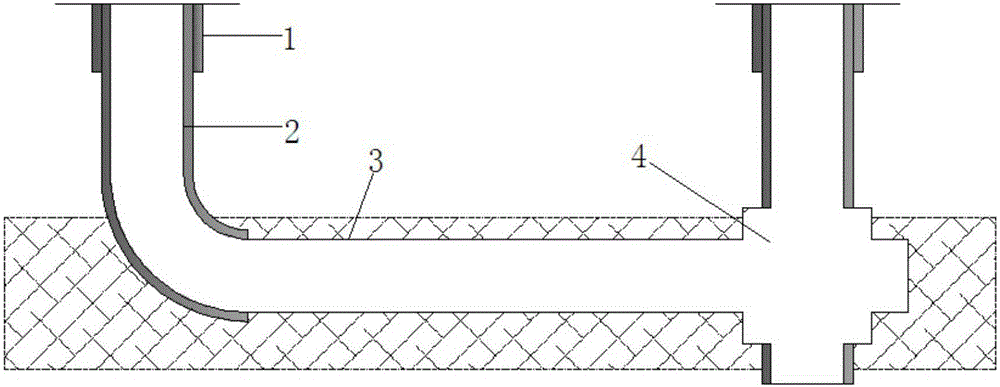

[0053] Before the well completion operation, firstly, the borehole diameter of the open hole is determined according to the wellbore stability of the coalbed methane horizontal well drilling and related theoretical practices, and the finite element analysis method is used to analyze the screen pipes with different mesh distribution schemes and flushing pipes with different specifications and sizes. Deformation displacement and stress calculations are carried out under parameters such as different lengths of horizontal sections, and combined with coal powder cementation, the preferred FRP screen is a combination of round holes and slots. The slot length is 80mm, width 6mm, circular hole diameter 8mm, axial The hole density is 21-22 pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com