A front-end dynamic hydraulic large-diameter graded cavitation device and method for pressure relief and anti-reflection

A large-diameter, power-type technology, applied in earthwork drilling, wellbore/well components, directional drilling, etc., can solve problems such as equipment capacity, structural limitations, and limited maximum hole radius, and achieve fast and easy hole creation Control, operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

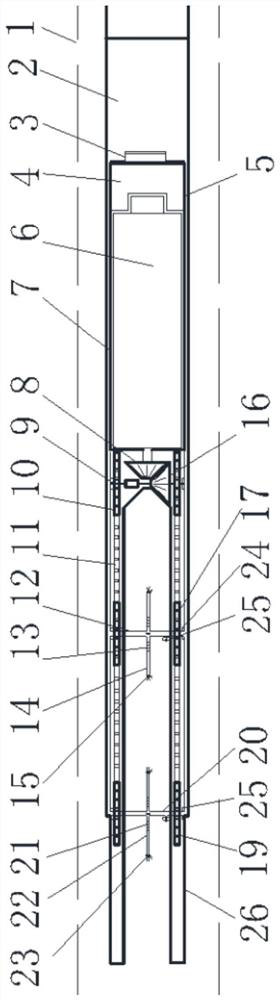

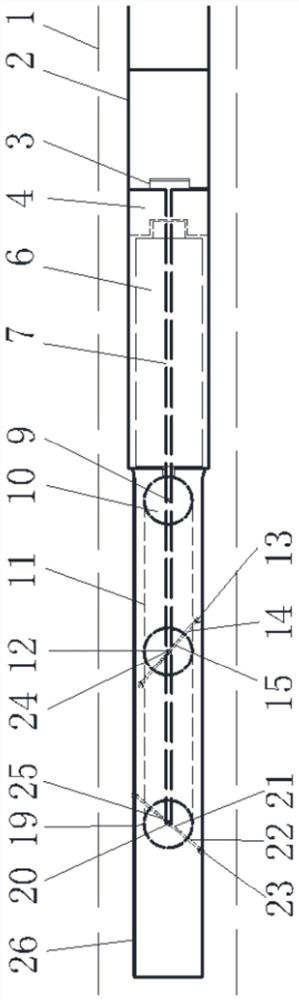

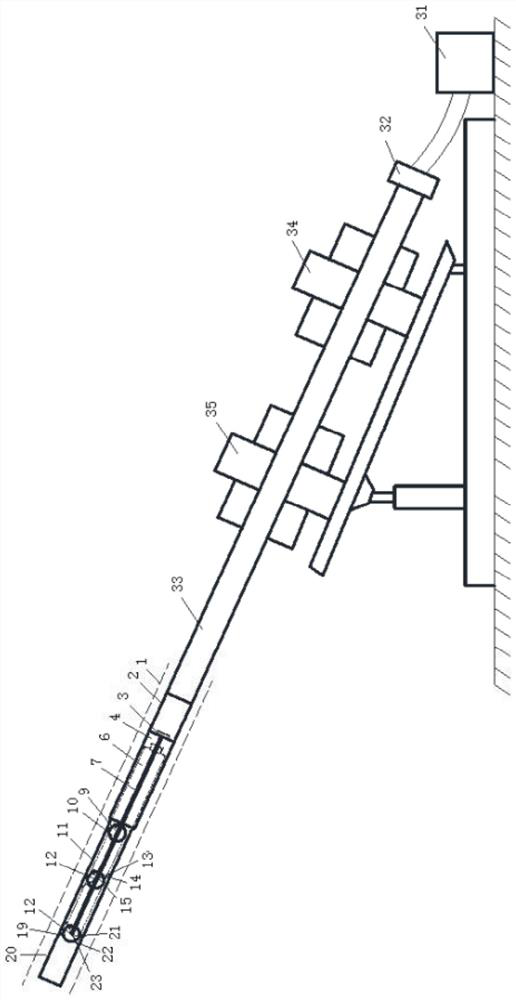

[0029] Such as Figure 1-Figure 3 As shown, this embodiment proposes a front-end power type hydraulic large-diameter graded cavitation pressure relief device, including a drill pipe 33, a graded cavitation drill bit 2 and a high-pressure water supply system, wherein the graded cavitation drill bit 2 is installed on the drill rod 33 The high-pressure water supply system is connected to the tail end of the drill pipe 33 and supplies water to the inside of the drill pipe 33. The graded cavitation drill bit 2 includes a housing, which is equipped with a motor power supply device 4, a front-end explosion-proof motor 6, and a motor-driven bevel gear. 8. The first transmission bevel gear 16, the driving cylindrical gear 10 and the transmission chain 11. The graded cavitation drill bit 2 also includes at least one set of transmission cylindrical gears, water guide transmission shaft and jet assembly, wherein the motor power supply device 4 is arranged at the front end of the explosion-...

Embodiment 2

[0040] This embodiment takes the technical solution of Embodiment 1 as the technology, and takes two jet components as examples to describe the structure and usage method of the device in detail.

[0041] combine Figure 1-Figure 3 As shown, a front-end power type hydraulic large-diameter graded cavitation pressure relief and anti-reflection device mainly includes a high-pressure water injection pump 31, a high-pressure water tail 32, a drill pipe 33, a first clamper 34, a second clamper 35, The graded cavitation drill 2, wherein the graded cavitation drill 2 mainly includes the front explosion-proof motor 6, the motor protection shell 5, the axially retractable motor switch 3, the motor power supply device 4, the motor transmission bevel gear 8, and the first transmission bevel gear 16 , the first transmission shaft 9, the first transmission cylindrical gear, the transmission chain 11, the second transmission cylindrical gear 17, the second water guide transmission shaft 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com