Explosion-proof pressure relief transformer

A transformer and pressure relief technology, which is applied in the field of transformers, can solve the problems of reduced strength of the bursting diaphragm, impurities left, uneven material, etc., and achieve the effects of high-speed pressure relief, vacuum pressure bearing, and fire risk avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

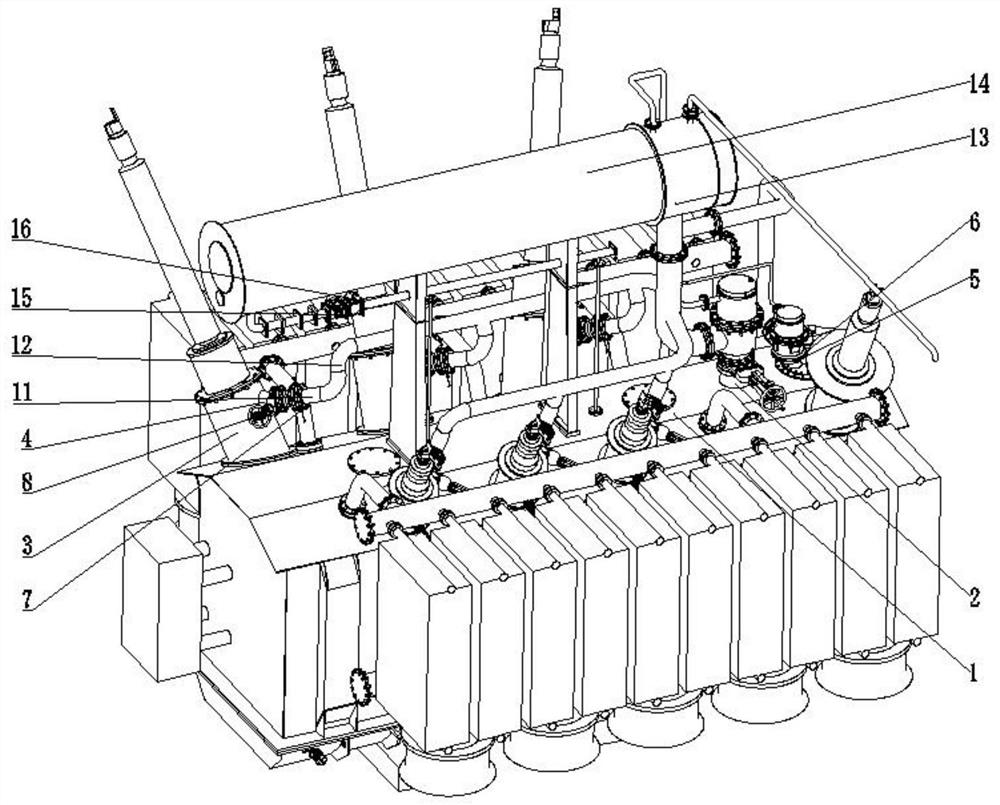

[0044] Such as figure 1 , Figure 5-Figure 18 Shown:

[0045] The invention provides an explosion-proof pressure relief transformer, which includes a transformer main body, on which a main oil tank pressure relief interface 2, a bushing riser seat pressure relief interface 4, and an on-load tap changer pressure relief interface 6 are provided; the main oil tank pressure relief interface 2. The pressure relief port 4 of the casing rising seat and the pressure relief port 6 of the on-load tap changer are respectively equipped with an anti-arch bursting disc pressure relief device; the pressure relief port 2 of the main oil tank, the pressure relief port 4 of the casing rising seat and the The pressure relief port 6 of the on-load pressure regulating switch is respectively connected to the inlet side of the reverse arched bursting disc pressure relief device, and the pressure relief side of the reverse arched bursting disc pressure relief device is connected to the oil discharge...

Embodiment 2

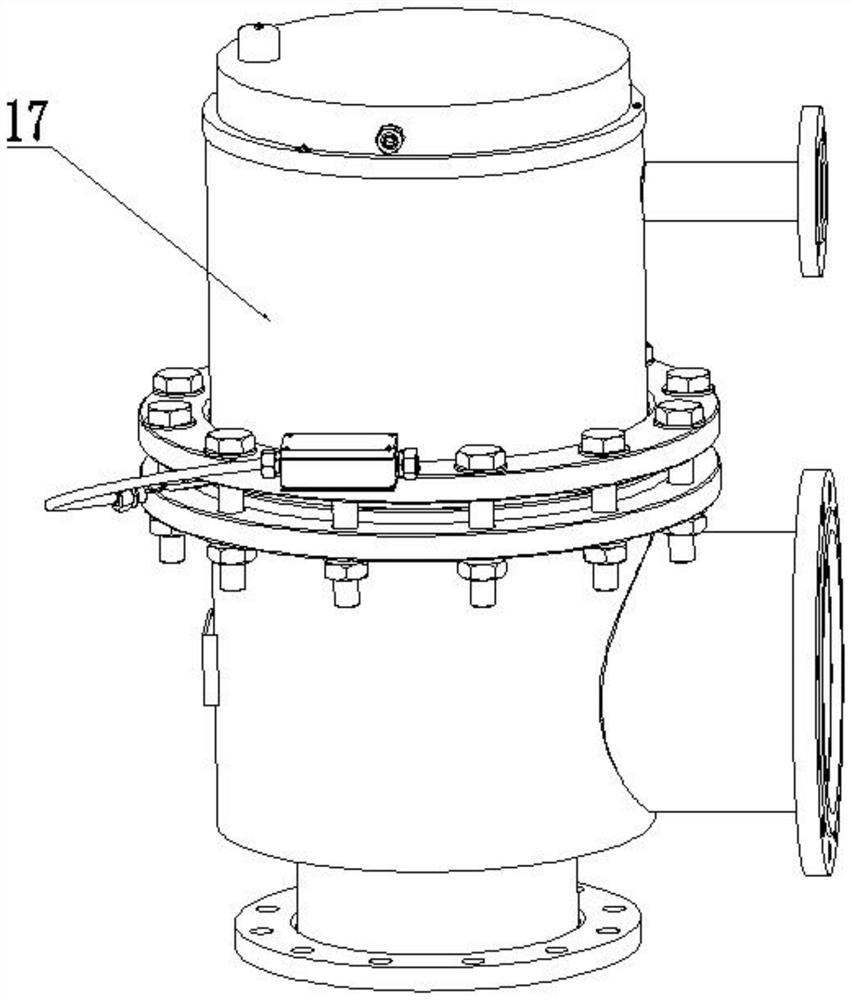

[0056] like figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0057] The difference between this embodiment and Embodiment 1 is that a high-speed pressure relief explosion-proof device (not shown in the figure) is used instead of an anti-arched bursting disc pressure relief device, and the main oil tank 1 or bushing riser 3 of the transformer may have On-load voltage regulating switch 5 carries out explosion-proof protection.

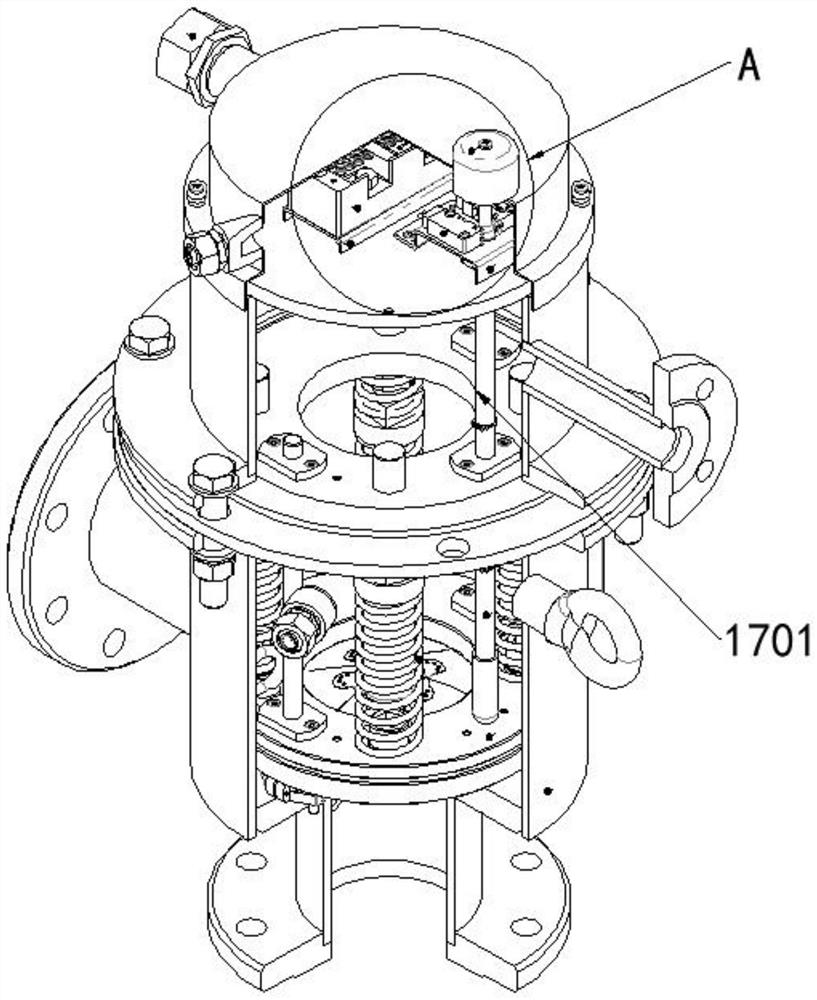

[0058] The invention provides an explosion-proof pressure relief transformer, which includes a transformer main body, on which a main oil tank pressure relief interface 2, a bushing riser seat pressure relief interface 4, and an on-load tap changer pressure relief interface 6 are provided; the main oil tank pressure relief interface 2. A high-speed pressure relief explosion-proof device 17 is respectively installed on the pressure relief port 4 of the bushing rising seat and the pressure relief port 6 of the on-load pressure regulator; the pres...

Embodiment 2

[0062] For Embodiment 2, the difference from Embodiment 1 is that the high-speed pressure relief explosion-proof device 17 is used instead of the reverse arched bursting disc pressure relief device and the decompression chamber 10. When the high-speed pressure relief explosion-proof device 17 starts to release pressure, the indicator rod 1701 Moving upward, during the movement, the indicator rod 1701 will touch the contact of the micro switch 1702 to make it appear in a closed state, and the status signal will be transmitted to other systems through the splitter 1703 in the circuit to realize the action signal alarm function . Other contents are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com