High-back-pressure miniature pressure relief switch for petroleum drilling

An oil drilling and high back pressure technology, applied in the field of oil drilling, can solve the problems of complex structure and inability to withstand excessive pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

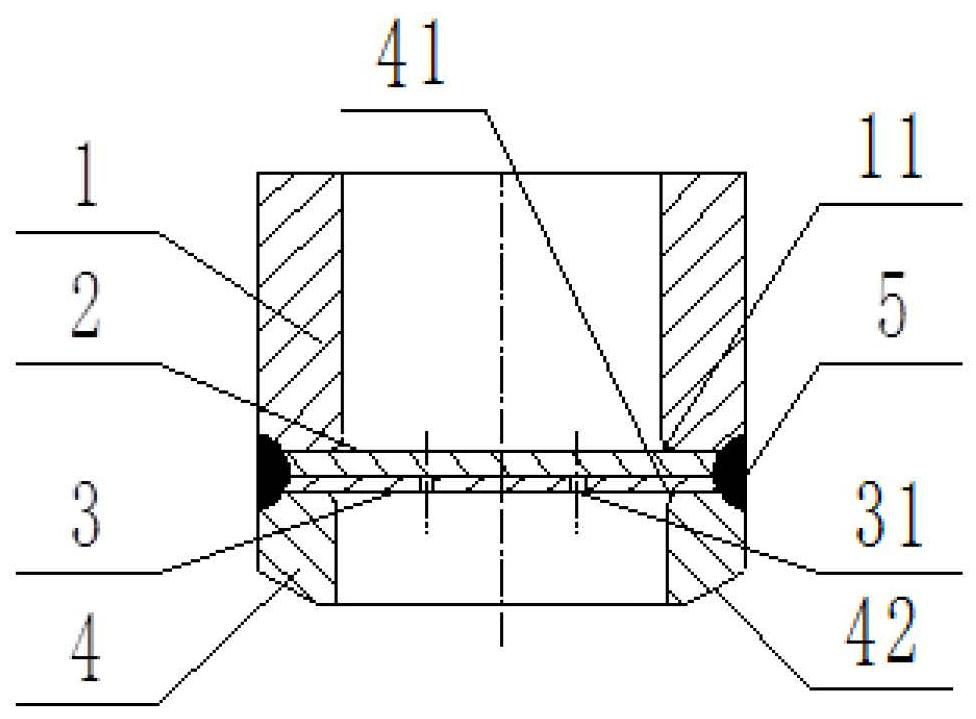

[0032] Such as figure 1As shown, the present invention provides a high back pressure miniature pressure relief switch for petroleum drilling, comprising: an upper pressure ring 1, a rupture pressure relief diaphragm 2, a back pressure resistant auxiliary diaphragm 3 and a sealing ring 4, the rupture relief The pressure diaphragm 2 is arranged at the lower end of the upper pressure ring 1, the back pressure resistant auxiliary diaphragm 3 is arranged at the lower end of the rupture pressure relief diaphragm 2, and the sealing ring 4 is arranged at the back pressure resistant auxiliary diaphragm 2. The lower end of the diaphragm 3, the edge between the upper pressure ring 1, the rupture pressure relief diaphragm 2, the back pressure resistant auxiliary diaphragm 3 and the sealing ring 4 are welded together by argon arc welding; The upper pressure ring 1 is in close contact with the rupture pressure relief diaphragm 2, and the inner surface of the upper pressure ring 1 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com