Accessory For Converting Excavators

a technology for excavators and accessories, applied in mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of two types of expensive machines and the limited use of excavators for earth-moving tasks, and achieve the effect of convenient loading and unloading operations, less time and effort, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

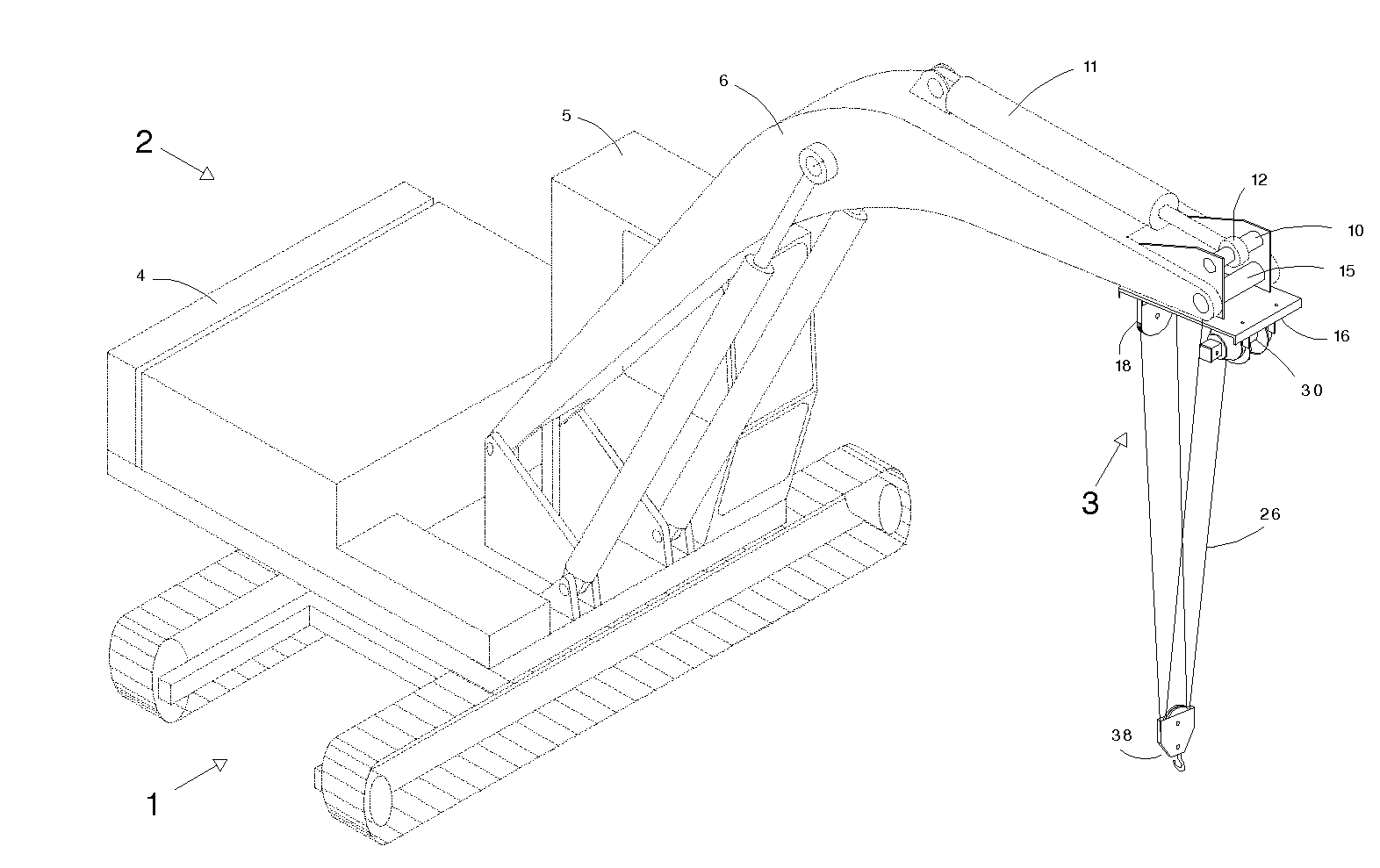

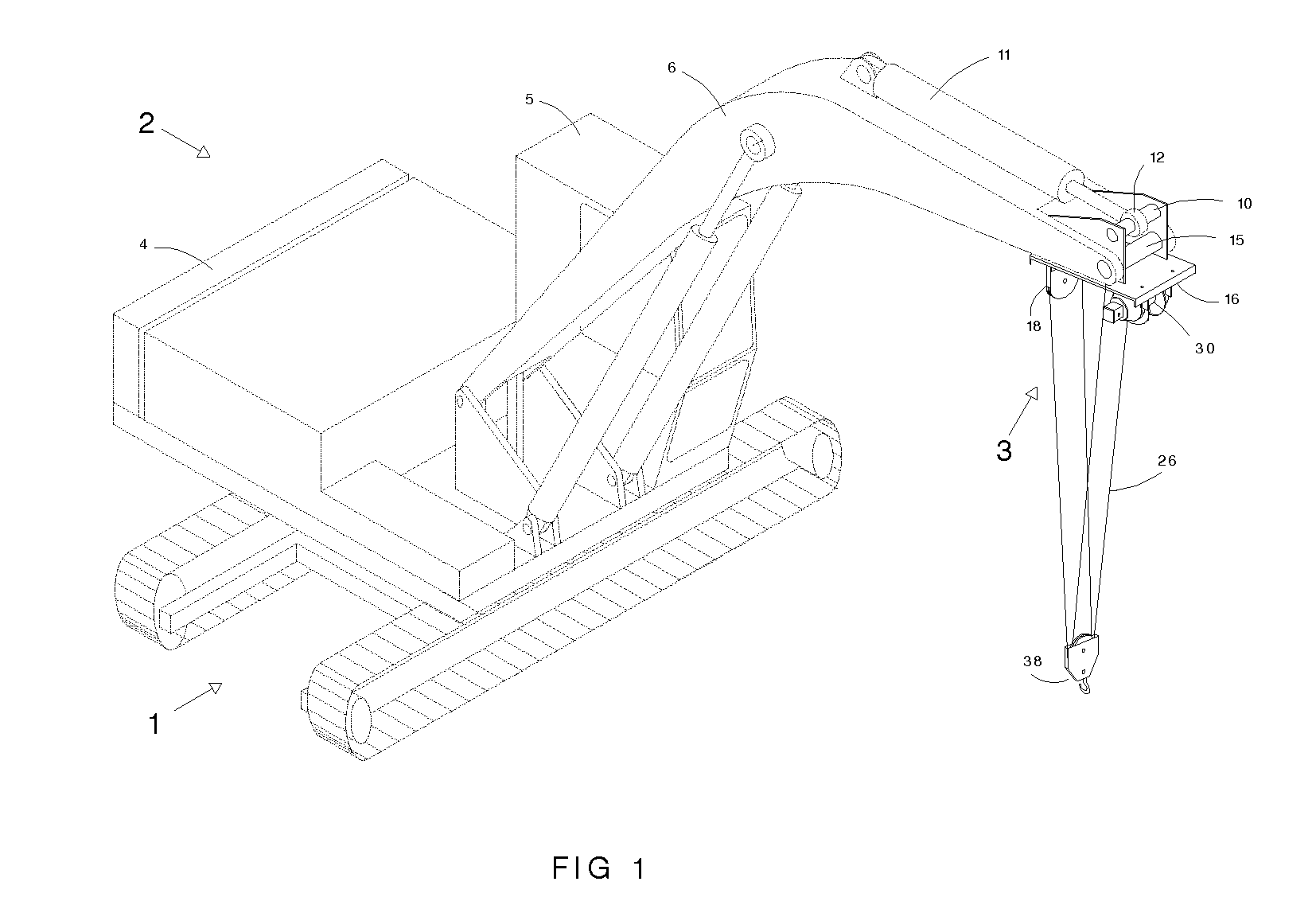

[0032]FIG. 1 shows (in dotted lines) an excavator equipped with the proposed accessory ready to operate in the pipe-laying mode. The jib, the bucket or work tool and the system for activating the bucket movement have all been removed. The upper body (2) is turned at an angle of 90 degrees to the lower body (1). Likewise, the counterweight (4), the operator's cabin (5), the excavating arm cylinder (11), the boom (6), the pin (15) that connects both the jib and the accessory (3) used in the pipe-laying mode to the top of the boom (6) are all visible.

[0033]The accessory (continuous lines) consists of a frame, a winch (30), the sheave (18) and a sheave with a lifting hook (38).

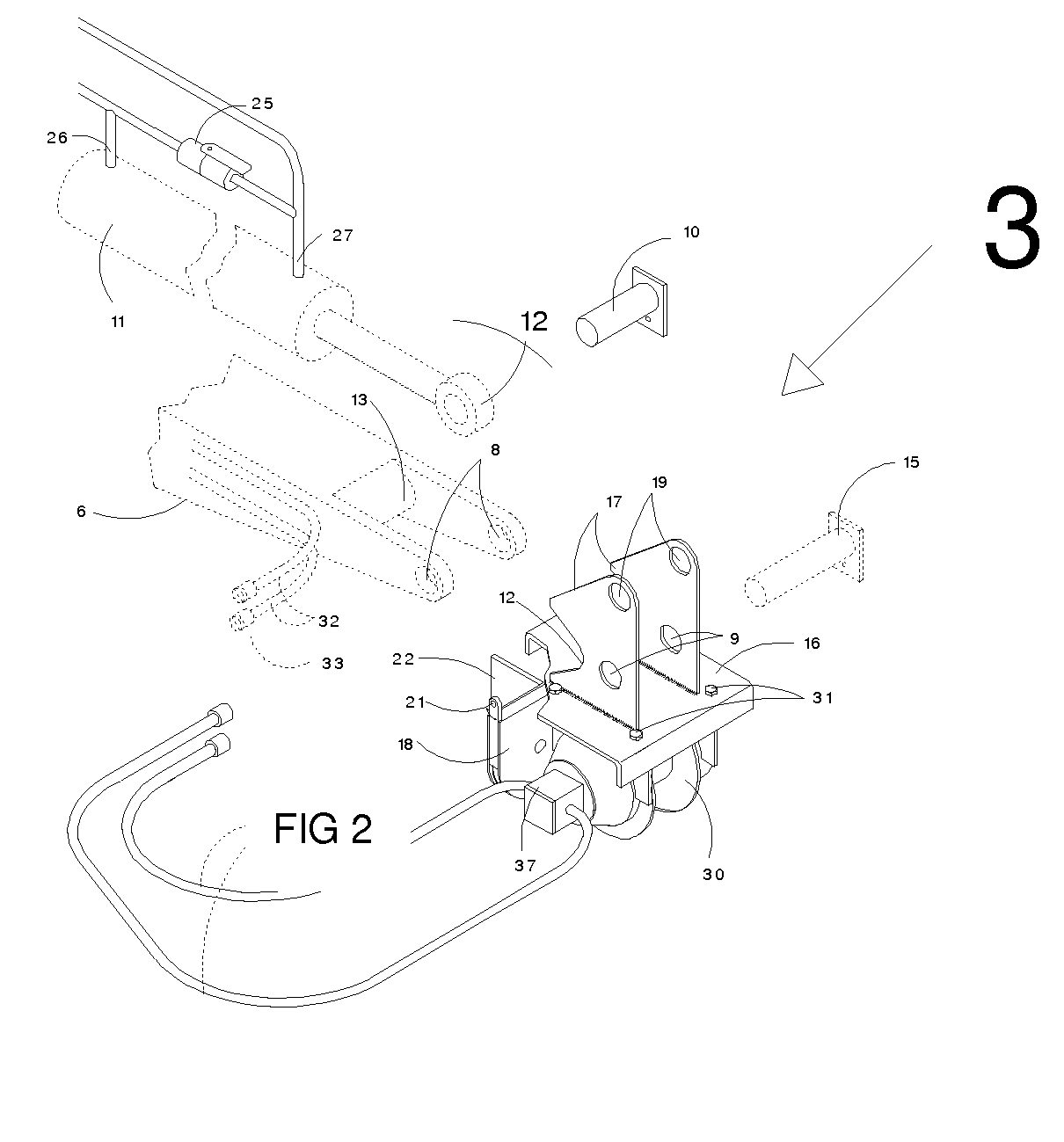

[0034]FIG. 2 shows in greater detail (in dotted lines) the top of the excavator boom (6) in pipe-laying or crane mode, the jib hydraulic cylinder (11) and the hydraulic fluid supply and return lines (32) of the bucket operating cylinder. Likewise, the rapid couplings (33) for connecting the hydraulic fluid flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com