Tee joint forming die and tee joint forming method

A technology for forming molds and tees, which is applied in the direction of manufacturing tools, broaching machines, broaching devices, etc., can solve the problems of affecting the flow rate of air-conditioning and refrigeration system pipes, thinning of product bending parts, and poor consistency of tee forming. Appearance quality, reduced product scrap rate, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

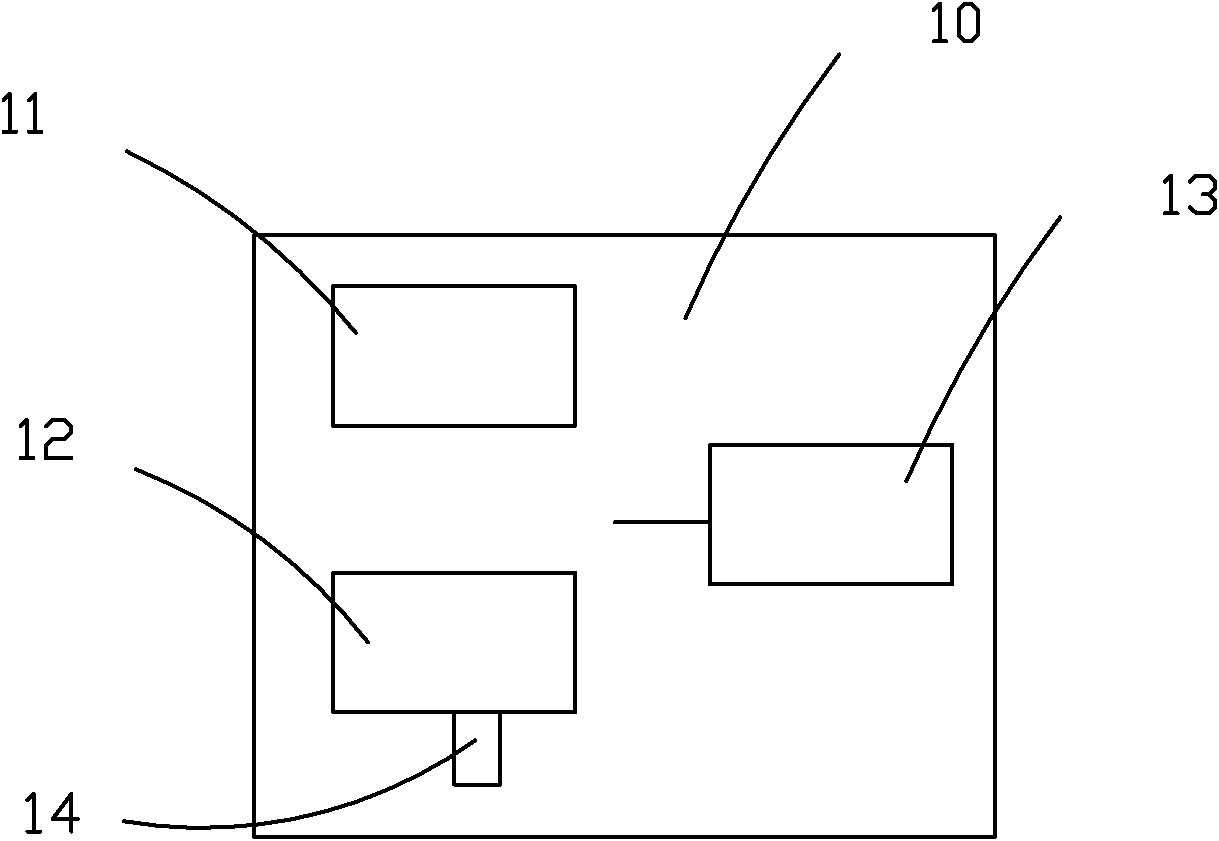

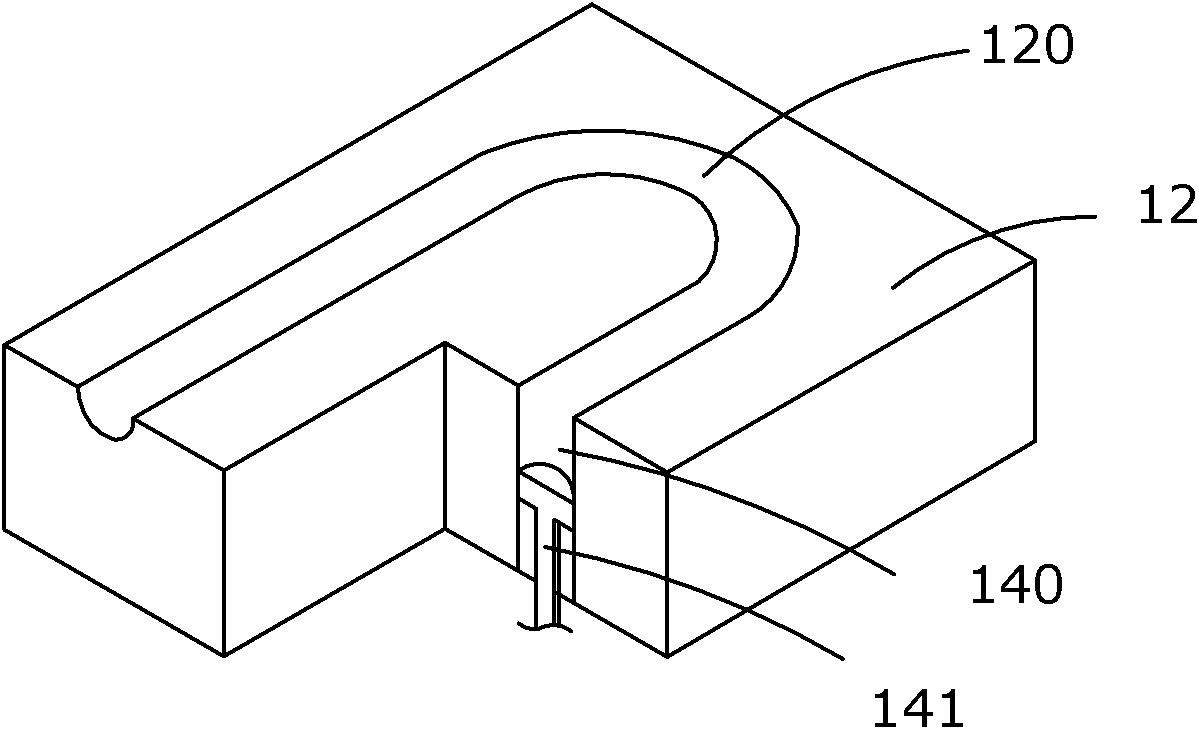

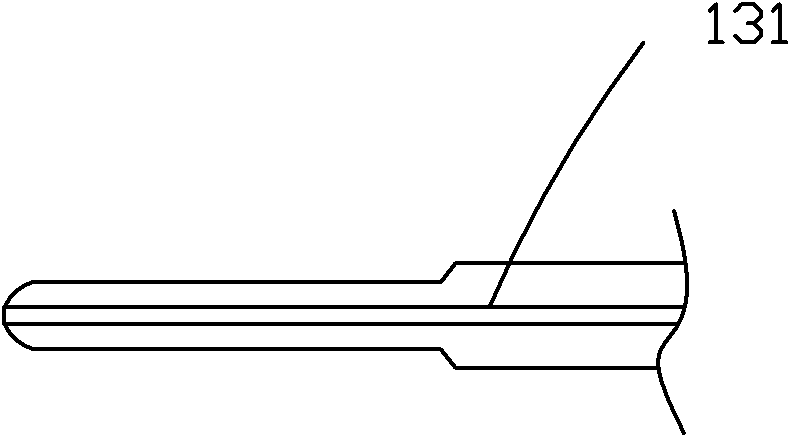

[0032] The tee forming die of the present invention is composed of an upper die 11 and a lower die 12 . See figure 1 , The three-way forming equipment also includes a hydraulic press 10, a hydraulic cylinder 13, a thimble 131, a support cylinder 14 and a control system. The upper die 11 is installed on the upper cylinder of the hydraulic press 10 and is controlled by the control system to move up and down in the vertical direction. The lower die 12 is placed on the platform of the hydraulic press. The support cylinder 14 is used to control the extrusion length of the three-way branch pipe. The function of the thimble 131 is to The two main ports of the workpiece clamped and fixed by the upper and lower molds are completely blocked, and the liquid filling process is carried out to squeeze the three-way workpiece to form the workpiece into a three-way. The thimble structure can be that one is connected to the hydraulic cylinder, and the other is a sealed entity, and the liquid ...

Embodiment 2

[0041] Figure 4 , Figure 5 It represents a three-way processing mold structure in which the direction of the branch pipe and the main pipe are perpendicular to each other. see Figure 4 , A patrix 11 is provided with a U-shaped groove group consisting of eight U-shaped grooves, and the U-shaped grooves are arranged symmetrically in two rows, so that one-time processing of three links can produce 8 pieces at the same time, greatly improving labor productivity. Each of the four corners of the upper mold has a screw 21 to fix the upper mold on the hydraulic press, and a positioning pin 22 is respectively arranged on both sides of the U-shaped groove group of the upper mold. When the lower and lower molds are closed, the positioning pins 22 of the upper mold Insert it into the positioning pin hole of the lower mold to ensure accurate clamping of the upper and lower molds. See Figure 5 , the lower mold 12 is provided with a U-shaped groove group consisting of eight U-shaped ...

Embodiment 3

[0043] Figure 6 It shows a Y-shaped tee processing mold structure in which the branch pipe and the main pipe are on the same plane, and the direction of the main pipe port and the branch pipe port is opposite. As shown in the figure, upper mold 11 is provided with three Y-shaped grooves arranged side by side. The Y-shaped grooves are composed of U-shaped grooves and a straight groove connected to the bottom of the U-shaped grooves. The structure of the lower mold is the same as that of the upper mold. When the upper and lower molds are closed, the semicircular straight grooves of the upper and lower molds surround the three-way branch lumen for processing branch pipes. When the tee is processed, the U-shaped tee workpiece is placed in the U-shaped groove of the lower mold, the upper and lower molds are closed, and multiple thimbles are inserted into the cavity formed by the U-shaped grooves of the upper and lower molds at the same time to block the hole of the tee workpiece. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com