Output shaft chrome plating method and output shaft chrome plating fixture

A technology of output shaft and chrome plating, which is applied in electrolysis process, electrolysis components, etc., can solve problems such as uneven thickness of inner circle chromium layer, chrome collapse at the edge of small hole, chrome leakage at window and end face, etc., so as to shorten the processing cycle and reduce the The repair rate and the effect of preventing chromium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

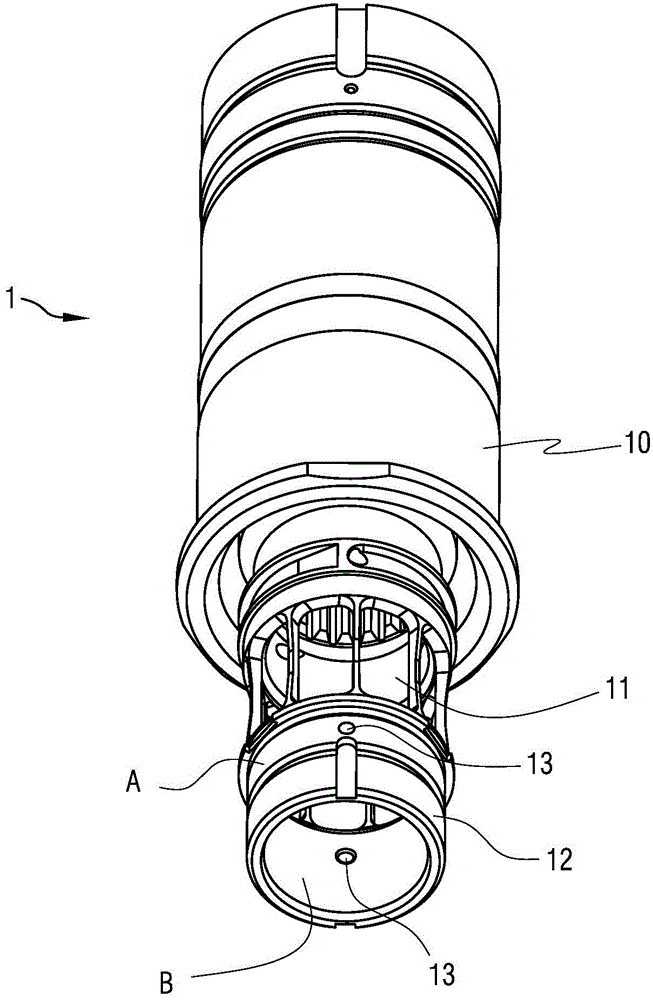

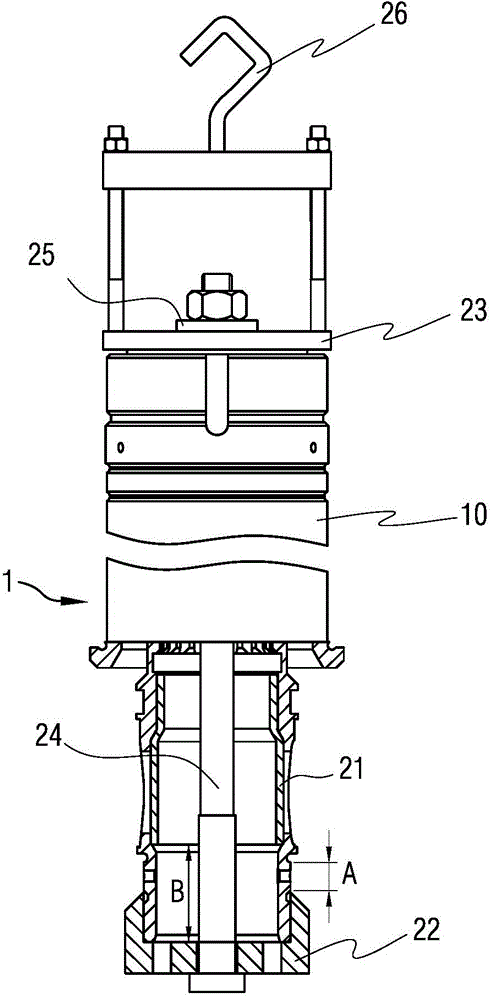

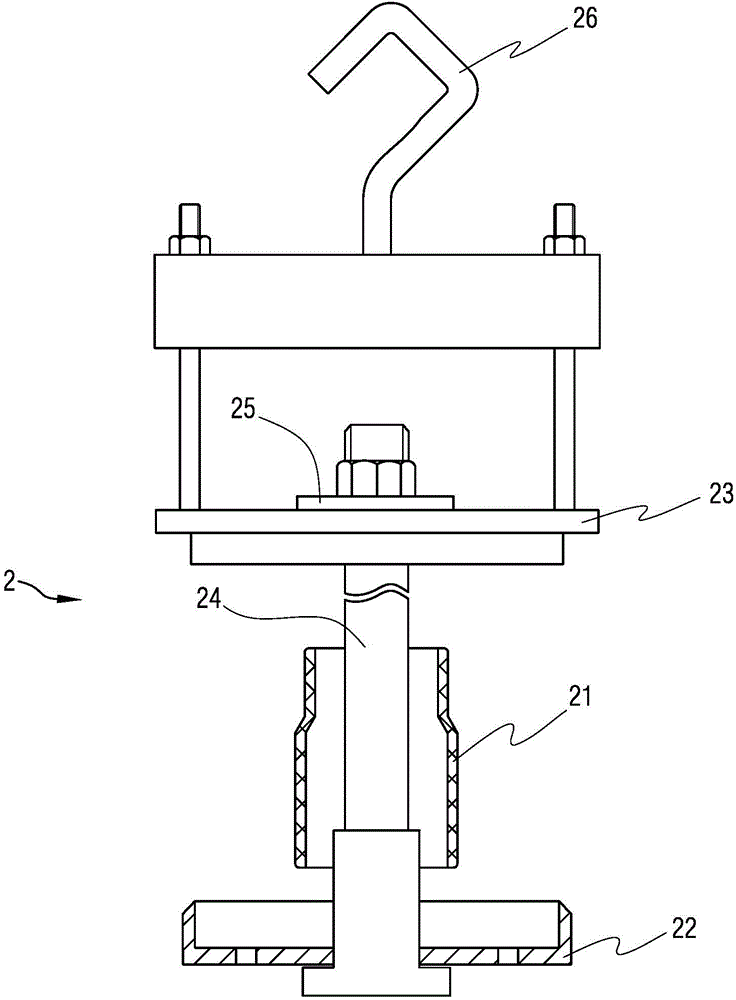

[0023] As described in the Background of the Invention section, the present invention provides a figure 1 The chrome plating method and fixture of the output shaft 1 shown. Specifically, figure 1 The shown output shaft 1 includes a cylindrical main body 10, the first end of the main body 10 has a chrome-plated outer circle area A and a chrome-plated inner circle area B; the chrome-plated outer circle area A and the chrome-plated inner circle There is a non-chrome-plated window area 11 formed by a plurality of windows above the area B; a non-chrome-plated outer circle 12 is provided on the outer side of the first end portion; the chrome-plated outer circle area A is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com