Strong resistance and strong evasion floor heave governing construction method of high-stress large-deformation soft rock drift

A large-deformation, high-stress technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of high repair rate, large amount of engineering, slow construction speed, etc., achieve large deformation buffer space, strong engineering practicability, and improve The effect of stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

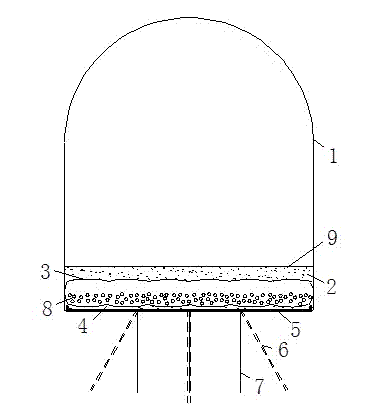

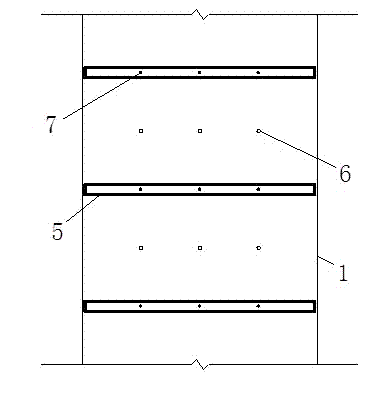

[0013] Attached below figure 1 And attached figure 2 Further illustrate the construction steps of the present invention.

[0014] (1) Considering the cross-section design size of the roadway 1, over-excavate the roadway floor 9 to the required depth.

[0015] (2) Arrange 18# channel steel beams 5 or I-shaped steel beams 5 of similar size on the floor of the roadway after over-excavation. The length of the steel beams 5 is determined according to the width of the roadway 1, and the row spacing of the steel beams 5 is 2000mm.

[0016] (3) Fix the steel beam 5 on the base plate with the high-strength threaded steel anchor rod 7, the diameter of the high-strength threaded steel anchor rod 7 is 20mm, the length is 1600mm, the distance between the anchor rods is 1000mm, and each anchor rod is anchored with a resin anchoring agent .

[0017] (4) Concrete 4 with a thickness of 50mm is poured, and the bottom plate of the roadway is closed.

[0018] (5) After the floor concrete 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com