Permanent magnet brushless motor with separated Hall position transducer and motor stator

A permanent magnet brushless motor and Hall position technology, applied in the field of motors, can solve problems such as immature technology, and achieve the effects of reduced repair rate, long service life, and convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

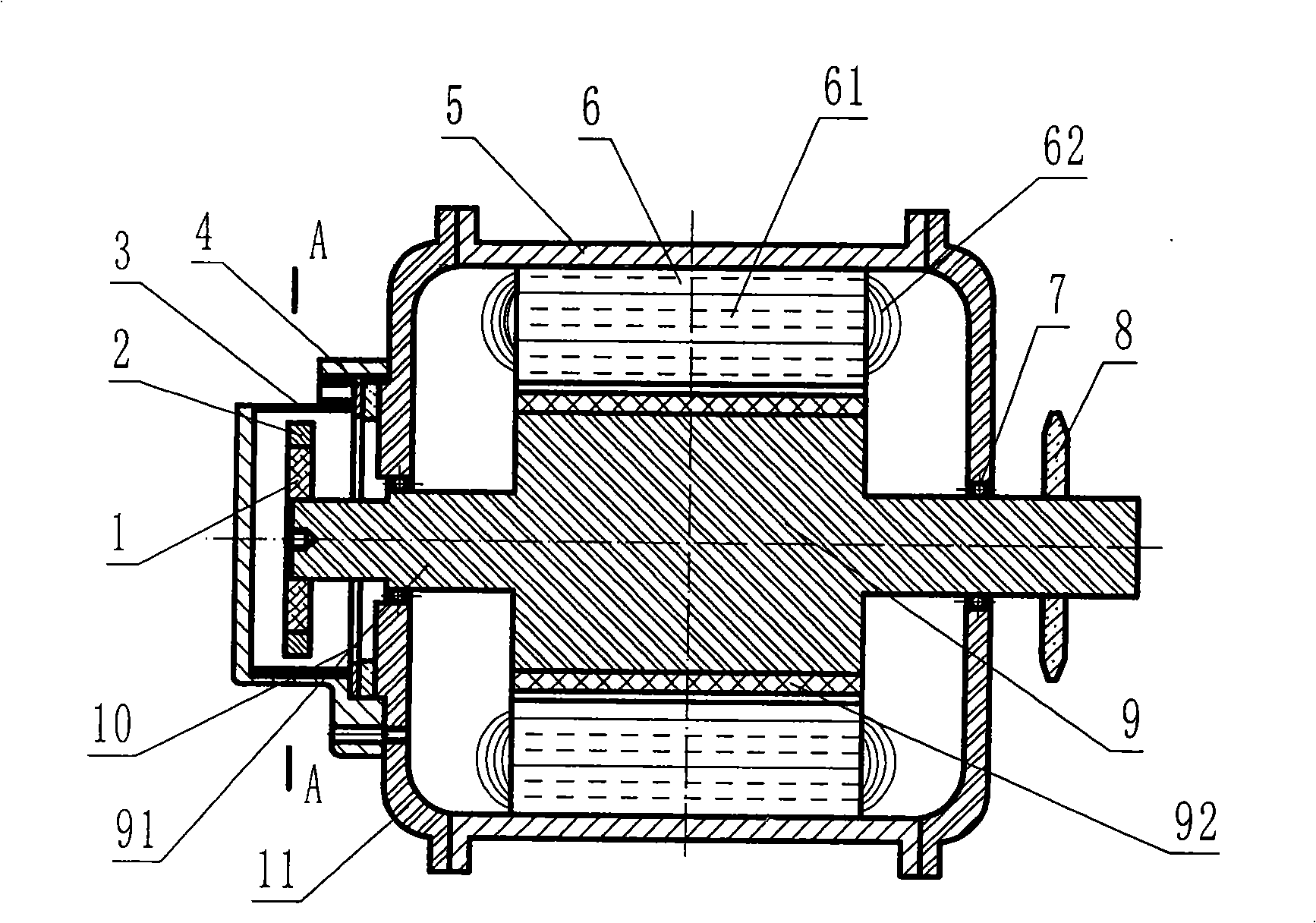

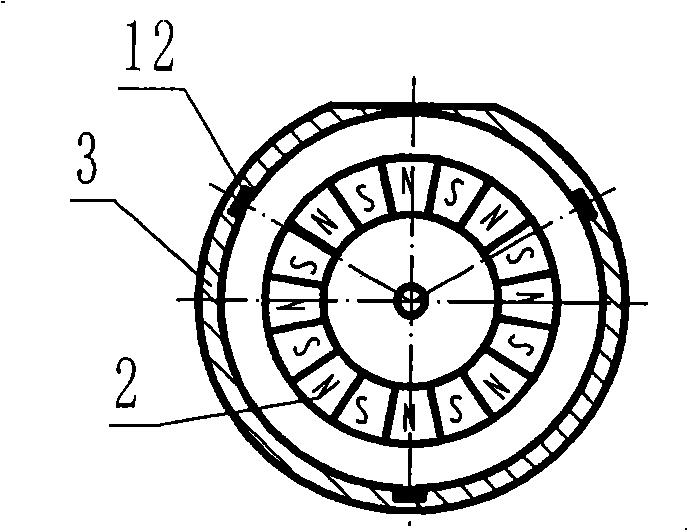

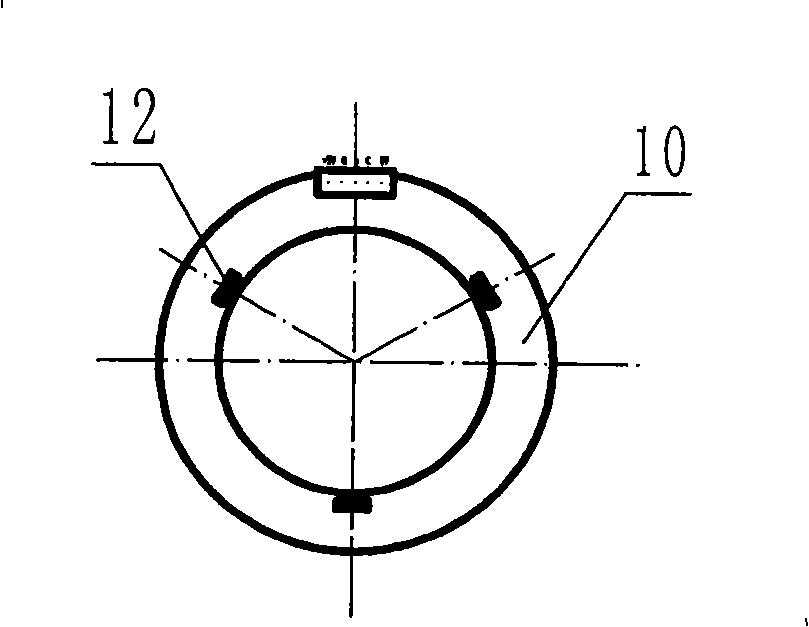

[0034] see Figure 1 ~ Figure 4 , the permanent magnet brushless motor placed separately from the Hall position sensor and the motor stator, including the permanent magnet rotor 9 of the motor, the motor stator 6, the motor shaft 91, the motor housing 5, the Hall position sensor 12 and the controller (not shown in the figure ), and a hall position sensor commutation sensing device placed separately from the motor stator 6, the device is provided with: a permanent magnet commutation rotor 1 and a matching commutation hall position sensor bracket 3, the permanent The magnetic commutation rotor 1 is connected and synchronized with the permanent magnet rotor 9 of the motor, the Hall position sensor bracket 3 is fixedly connected with the motor stator 6, and the Hall position sensor 12 is fixed on the Hall position sensor bracket 3 to be connected with the permanent magnet commutation The corresponding phase position of rotor 1. The permanent magnet commutation rotor 1 corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com